In this topic, you study Metal Halide Lamp – Working Principle, Construction & Circuit Diagram.

Metal halide lamps are basically compact high-intensity discharge lamps producing high light output and operating under the conditions of high pressure and temperature.

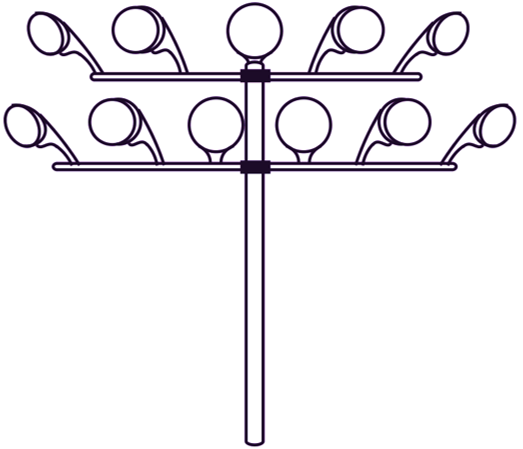

Fig. 1: Metal halide lighting pole at a sport field

Construction of Metal Halide Lamp

Metal halide lamp (Fig. 1) has a metal base and a glass shield to protect the inner components. Inside the glass shield, a series of support and lead wires hold the inner fused quartz or alumina arc tube with its embedded tungsten electrodes. The compact arc tube contains a high-pressure mixture of argon, mercury and a variety of metal halides (iodides or sometimes bromides of different metals).

Operation of Metal Halide Lamp

The argon gas in the lamp is easily ionized and facilitates striking of the arc across the two electrodes when voltage is first applied to the lamp. The heat generated by the arc then vaporizes the mercury and metal halides which produce light as the temperature and pressure increase. The mixture of halides affects the nature of light produced. Sometimes, a phosphor coating is provided on the inner side of the outer glass bulb (shield) to improve the spectrum and diffuse the light. Like other gas discharge lamps, metal halide lamps require electrical or electronic ballasts to regulate the arc current flow and deliver the proper voltage to the arc.

Applications of Metal Halide Lamp

Because of their availability in numerous sizes (150, 250, 575 and 1200 W ratings) and configurations, these lamps are now increasingly used for industrial, commercial and domestic applications. They are most often used in athletic facilities. They are preferred to mercury vapour lamps in instances where natural light is desired.

Advantages of Metal Halide Lamp

- Metal halide lamps are more efficient than fluorescent lamps and substantially more efficient than incandescent lamps.

- Longer lifespan.

Disadvantages of Metal Halide Lamp

In general, a cold metal halide lamp requires some starting or warm up time. It cannot immediately begin producing its full light because the temperature and pressure in the inner arc tube require time to reach full operating levels. However, now the lamps having ‘instant restriking’ capabilities, have also been developed. In this case, the lamp, ballast and socket are built to withstand 30 kV re-ignition pulse supplied via a separate anode wire.