Range: up to 40,000 r.p.m.

Accuracy: ±1

Centrifugal tachometer is the only mechanical tachometer having ability to detect the variations in the speed.

Centrifugal Tachometer Principle of Working

When a body revolves about an axis, it experiences a radially outward force. This force is called as centrifugal force. This centrifugal force is a function of rotational speed. Therefore, it is used to measure instantaneous speed by means of centrifugal force.

Construction of Centrifugal Tachometer

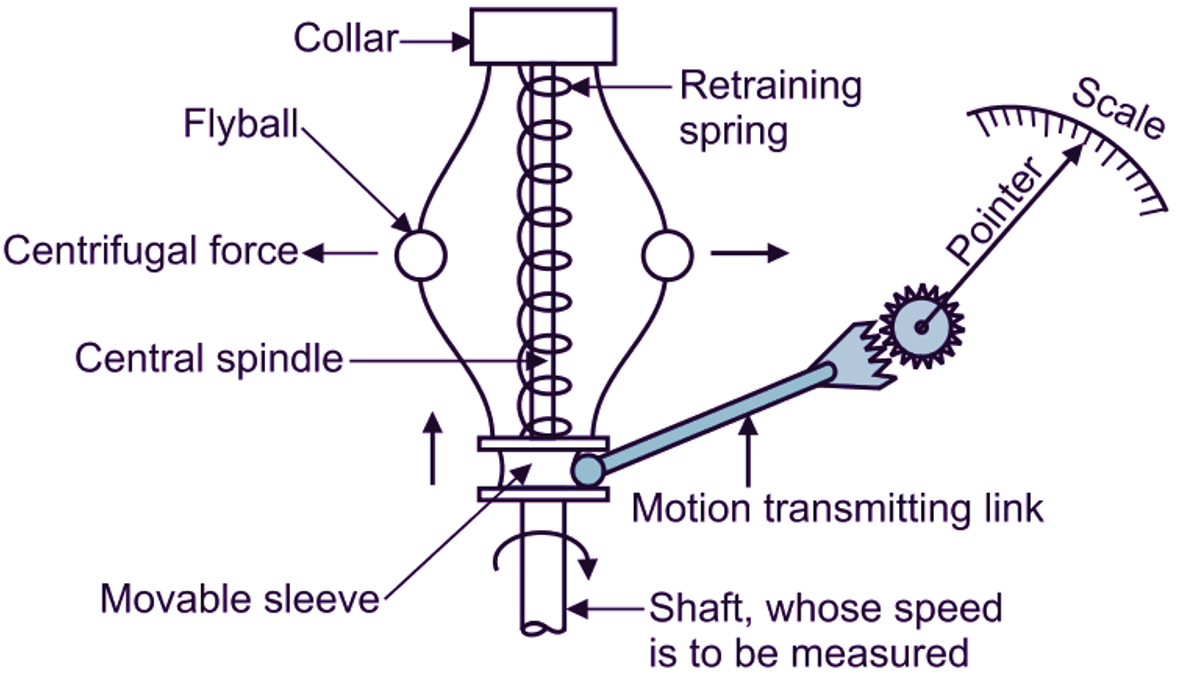

Two fly balls of small weights are arranged about a central spindle. Driver shaft, whose speed is to be measured, is connected to this spindle.

Fig. 1: Centrifugal Tachometer.

Working of Centrifugal Tachometer

As soon as driver shaft is connected to this central spindle, central spindle starts rotating. Due to rotation of central spindle, a centrifugal force is developed, which causes the fly balls to move outwards in radial direction, i.e. away from the spindle. When fly ba Is move away from central spindle, spring wounded on the spindle is compressed. Value of this compression or decrease in length of spring becomes a function of rotational speed and accordingly, the pointer is moved on a calibrated scale, which is a measure of shaft speed. As soon as, driver shaft is disconnected from centrifugal tachometer, the spring is restored to its original length. Fly balls move towards the central spindle and occupy their original position.

Advantages of Centrifugal Tachometer

- It has accuracy of ±1

- It is used to measure speed over wide range.

- Constant speed is shown.

- Simple to operate.

- Easy in maintenance.

Disadvantages of Centrifugal Tachometer

- High speed may damage the instrument.

- It cannot be placed horizontally. It needs to be placed in vertical direction only.