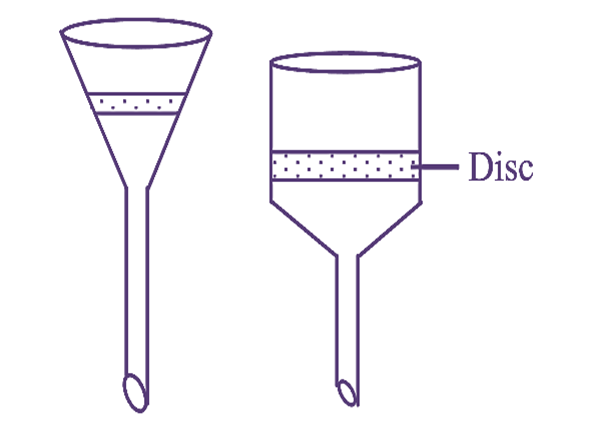

Figure 1: Sintered Glass Filter.

Working & Construction of Sintered Glass Filter

The sintered glass filter is manufactured by powdering high-grade borosilicate glass (see Figure 1). The finest particles are separated arid sintered into discs in suitable moulds. The discs are fused into Buchner-type funnel.

Sintered glass filters are available in different grades. Grade 5 (maximum pore size not more than 2 µm) is used for removing bacteria. Grade 3 removes foreign organic matter. These filters inhibit microbial growth if left for more than 18 hours. Sintered metal (bronze or stainless steel) filters have also been developed. They possess high mechanical strength but may react with the solutions to be filtered.

A stream of water is passed in the reverse direction of the filter so as to clean it. Concentrated sulphuric acid (H2S04) containing 1 to 2

Advantages of Sintered Glass Filter

- Negligible adsorption of medicaments.

- The volume of filtrate retained in the medium is less than compared to ceramic types.

- If desired, holders can be fused into glass filtration units, thus reducing the number of possible leakage points. This facilitates cleaning.

- Cleaning the filter is easy.

Disadvantages of Sintered Glass Filter

- Removal of toxins and pyrogens is not possible.

- Leakage of non-sterile air occurs if vacuum is used.

- Prolonged filtration causes clogging of the filter and growth of bacteria.

- Candles and fibrous pads adsorb the constituents of the solution.

- They are expensive.

- The surface area for filtration is small.