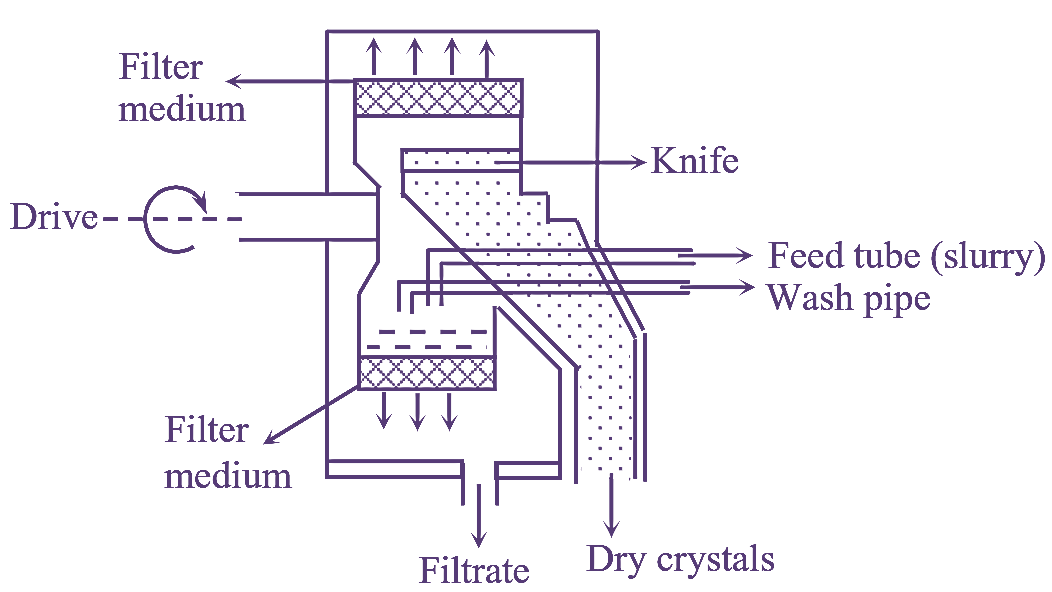

Figure 1: Semi-Continuous Centrifuge.

Working Principle of Semi Continuous Centrifuge

Perforated semi-continuous centrifuge, also known as short cycle or automatic batch centrifuge works on the principle of filtration. The separation occurs through a filter medium (i.e., perforated wall) based on the difference in the densities of solid and liquid phases.

Construction of Semi Continuous Centrifuge

- It consists of a vertical perforated basket which rotates on a horizontal axis (see Figure 1).

- The slurry to be filtered is introduced from the feed tube.

- Wash pipe (for washing the filter cake) is also introduced parallel to the feed pipe.

- The feeder controls the thickness of the feed and automatically stops its supply.

- When the discharge of crystals is desired, the hydraulic cylinder is attached in such a way that the discharge chute enters the basket from its sides.

Working of Semi Continuous Centrifuge

- Feed is introduced in the basket through the feed tube.

- The basket is allowed to rotate along the horizontal axis.

- Due to the process of centrifugation, solids get retained in the filter in the basket and the filtrate leaves the basket from its outlet. The solid crystals are washed and the washed water is drained out which leaves from the outlet. The feeder maintains the feed thickness i.e., a thickness of 50-70 mm is preferred.

- When the hydraulic cylinder is attached along with the discharge chute, the knife is lifted. It cuts the filter cake such that a layer of crystals is left back. This layer of crystals now sewed as a filter medium in the next cycle.

- The feeder and the hydraulic cylinder makes the process semi-automatic, hence the name semi-automatic/semi- continuous centrifuge.

- The crystals obtained contain 2-4

Advantages of Semi Continuous Centrifuge

- Semi-continuous centrifuge is semi-automatic.

Disadvantages of Semi Continuous Centrifuge

- Crystals may break while discharging.

- Designing and operation of the centrifuge is complicated.

- Increased labour requirement.

- Higher power consumption.