In this topic, you study Hysteresis Loss.

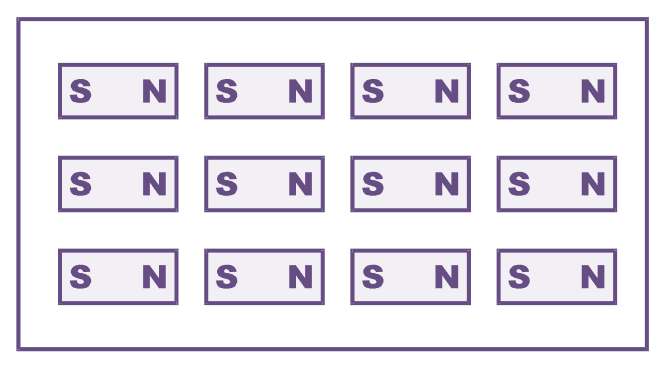

When a magnetic material is magnetized, the magnetic axes of the various domains are oriented so that they coincide with the direction of the externally applied magnetomotive force (see Figure 1). This process always requires some energy.

Figure 1.

This energy is stored in the magnetic field that is built up. But due to characteristic property of hysteresis exhibited by magnetic material, all the energy that is stored in the magnetic field is never returned to the circuit when the mmf is removed and the field is allowed to collapse.

The loss of energy which ultimately appears as heat in the specimen of magnetic material is known as hysteresis loss. The repeated process of magnetization and demagnetization when the magnetic material is carried through a cycle of magnetization always causes disturbance in the alignment of various domains and thereby produces hysteresis loss.

The magnetic circuits (or magnetic cores) in many electrical equipments are subjected to a varying (or alternating) magnetic flux.

The hysteresis loss which is produced in the magnetic circuit under such condition being high, it always reduces the efficiency of the electrical equipment and causes undesirable temperature rise due to heat that results.

The hysteresis loss in the magnetic material depends upon the following factors and varies in direct proportion with them.

- The area of the hysteresis loop. This area in turn depends on the nature (composition) of the magnetic material and the peak flux density to which the material is magnetized.

- The frequency i.e. number of cycles of magnetization per second.

- The volume of the magnetic material.

It can be shown that quantitatively, the hysteresis loss in joules per cubic metre of material in one cycle is equal to the area of the hysteresis loop. Here it is important to remember that while calculating the actual loop area, scale factors of B and H must be taken into consideration.

Hence, hysteresis loss in the electrical equipments is reduced by using the magnetic material for the core with a narrow hysteresis loop. Silicon steels (silicon-iron a loys) are commonly used for this purpose.

In practice, hysteresis loss for ferromagnetic material is often found with reasonable accuracy using following empirical law devised by Steinmetz on the basis of experimental studies. The results are more accurate when the maximum flux density is between 0.1 and 1.2 T.

\[\text{Hysteresis loss }{{\text{P}}_{\text{h}}}={{K}_{h}}B_{m}^{1.6}\text{ f}\text{.v watts}\]

Where,

Kh = A characteristic constant called Steinmetz hysteresis co-efficient for the material

Bm = Maximum flux density, in teslas

f = Frequency i.e. number of cycles of magnetization per second

v = Volume of the magnetic material, in cubic metres.

Equation (1) also suggests following additional measures to reduce the hysteresis loss :

And additional measures to minimize the hysteresis loss may include proper mechanical handling and heat treatment for the magnetic material, adoption (if possible) of low frequency and low working flux density.