Coordinate measuring machine (CMM) is one of the most important equipment used in the contact type inspection process of parts. It is a flexible measuring machine widely used in manufacturing industries for post production inspection of components.

Construction of Coordinate Measuring Machine (CMM)

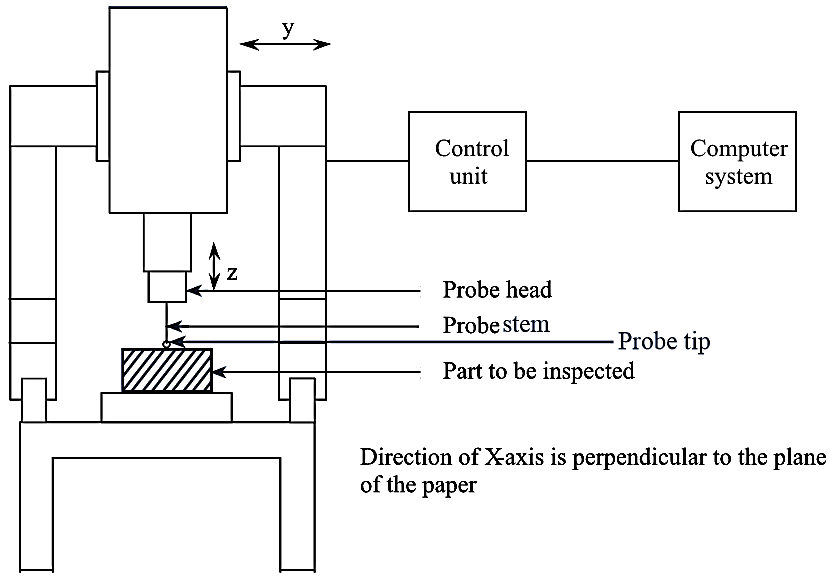

Figure 1: Coordinate Measuring Machine (CMM).

The basic elements of CMM are as follows,

- Rigid mechanical structure

- Probing system

- Control unit

- CMM software.

Rigid Mechanical Structure

It is a rigid structure, and serves as a main operating unit of CI’L where it incorporates the various guideways and probing system. It allows the movement of sensor probe in X-Y-Z direction to position it in required position on the component to be measured. The movements can be controlled either by computer numerical control (CNC) or manually. Air bearings are provided for the liner motion to reduce the vibration and effects caused during high speed and high acceleration conditions. Thermally stable surfaces such as granite tables are used as base for placing the part to be measured. Based on the construction of mechanical structure, different of CMMs are available. They are,

- Cantilever type

- Bridge type

- Colunm type

- Horizontal arn type

- Gantiy type.

Probing System

The measuring head of the CMM is incorporated with the touch trigger probes to record the coordinates (x,y,z) of the points where the probe touches the component to be measured. The stem of the probe is made of tungsten, steel, ceramics and titanium whereas the tip of the probe is made of ruby, silicon nitride and zirconia. These probes are faster and accurate in measurement. For ilon-contact type measurements, an opto-electronic sensors are used instead of touch trigger probes.

Control Unit

It controls the positioning of probe and movements of various spindles in x-y-z directions. It collects data in the form of measured point sets, which is an input for CMM software for further calculations.

CMM Software

It is the operating system of CMM. It consists of various types of application programs. This software enables the CMM to do required calculations on the point sets and this data is exchanged between the other equipment in the CMM. Based on the type of industry, number of application softwares are available.

Working of Coordinate Measuring Machine (CMM)

During its working, the sensing probe is made to contact with the surface of the part. Then, the three coordinate positions are marked with greater accuracy, by moving the probe in required direction (Figure 1). The accuracy may be of 2.6 + L / 300 micrometers, where ‘L’ indicates the measured length in mm. The movement of probe can be obtained either manually or by means of a programmable computer system. The coordinate data can be obtained from the computer, as CMM is monitored using a computer. This reduces the time of inspection process. The major disadvantage is that, it also leads to the wastage of time dime to transportation of components for inspection, as CMMs are placed away from the production machines.

Advantages of Coordinate Measuring Machine (CMM)

- It saves time and maintains consistency in the process.

- High degree of accuracy can be obtained.

- Less skilled operators are required for the inspection

- Reduces the setting up and fixing time.

- Less maintenance is required.

- Process is simple and reliable.

- Eliminates the human errors.

- Highly precise and reduce inspection time.

- More flexible compared to conventional machines.

Disadvantages of Coordinate Measuring Machine (CMM)

- These machines cannot be moved or transferred from one place to other.

- The cost associated with the machine is high.

- It is difficult to restart the system.

- If the probe of CMM cannot reach some contour shapes, some special features are required.

Features of Coordinate Measuring Machine (CMM)

- In CMMs all systematic errors are fed to an integrated computer Thus. an error compensation is built up into the software.

- All CMMs are provided with a dedicated computer with a friendly software.

- Temperature gradients in the machine is compensated by a computer interfaced with the thermocouples. Thus, the accuracy and repeatability of machine is higher.

- By using CMMs with dedicated computers, a 3-D object can be measured from variable datums. This is possible by three-axis programming.

- Due to high flexibility and simple programming, CMMs can be used for any measuring requirement within the capacity of machine.

Applications of Coordinate Measuring Machine (CMM)

- Inspection of gauges and standard parts.

- Air craft and ship building areas.

- Inspection of cast iron and steel in automotive industries.

- Used in machine tool, automobile, electronics, space applications and used for development of new products and construction of prototype

- Used for the testing and inspection of gauges, tools and test equipment

- Used for determining dimensional accuracy of the bought in components and to check the quality of supplied components.

- 100

- Used for sorting tasks to achieve optimum pairing of components with tolerance limits.

- Used to check the dimensional accuracy of NC machine produced jobs