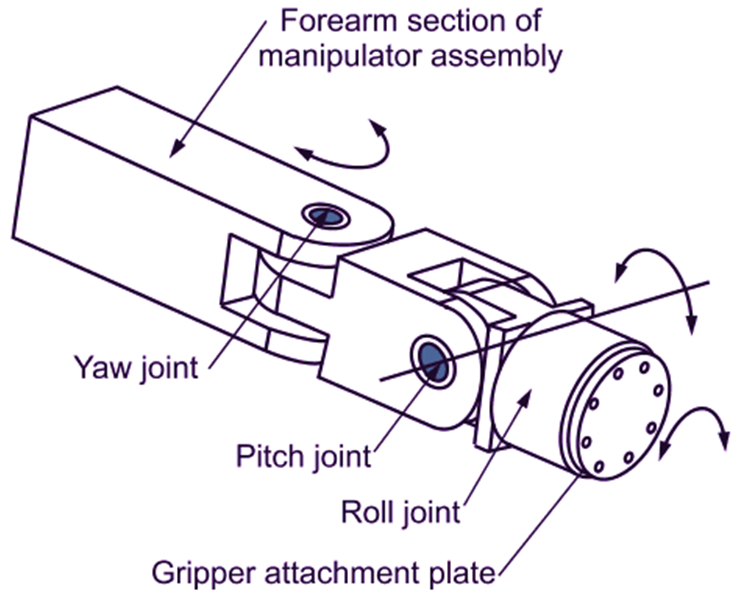

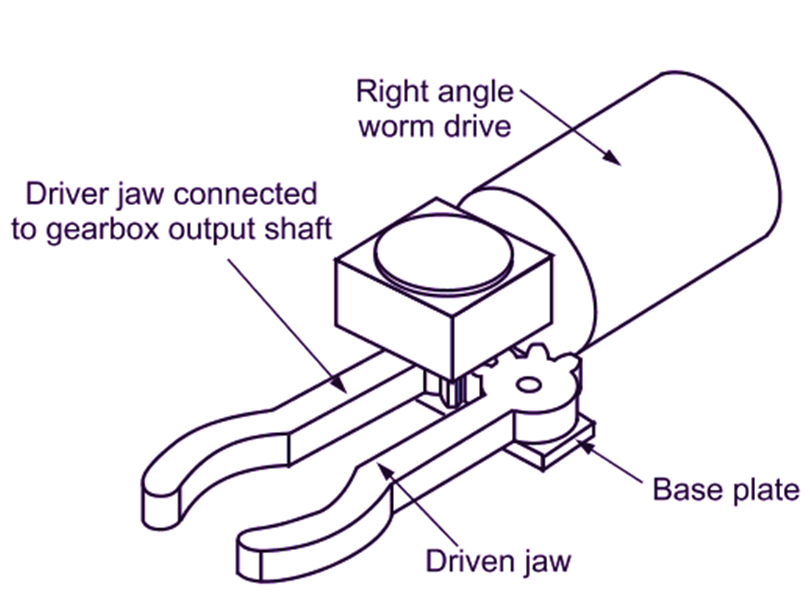

Grippers are mainly used in a robot for grasping/holding an object. The grasped objects will be moved to the preferred place with the help of a robot. A gripper can be defined as ‘a robot end effector that performs the operation to grasp temporarily, retain for required duration and re ease subsequently an object of a particular geometrical shape’. The gripper can be attached to the manipulator through a gripper plate as shown in Fig. 1. The grippers are capable of carrying work parts, bottles, tools and so on. It can work by means of magnetic, mechanical, vacuum cups etc. It is often used to pick up dangerous or suspicious items for the robot to carry. Some can turn doorknobs and others are designed to carry only very specific things like beer cans. Closing too tightly on an object and crushing it is a major problem with autonomous grippers. There must be some way to tell how hard is enough to hold the object without dropping it or crushing it. Even for semi-autonomous robots where a human controls the manipulator, using the gripper effectively, is often difficult. For these reasons, gripper design requires as much knowledge as possible of the range of items the gripper will be expected to handle. Their mass, size, shape and strength, etc. all must be taken into account. Some objects require grippers that have many jaws, but in most cases, grippers have only two jaws. There are several bast types of gripper geometries. A simple gripper with two jaws geared together is shown in Fig. 2. Grippers can be classified into mechanical groper, vacuum based, magnetic type, adhesive gripper etc.

Fig. 1: Manipulator Arm Showing Gripper Attachment Plate.

Fig. 2: A Mechanical Gripper.

Mechanical Gripper

The mechanical gripper can be actuated by means of gear, cam, links, rope and pulley, screw etc.

Vacuum Gripper

Vacuum grippers are vacuum actuated suction cups. The shape of cup depends upon the application for which it is to be used. Vacuum power is used to create grip and so used to lift smooth fragile objects such as plastic sheets, glass or thin metal sheets. But this consumes lot of power. Vacuum End Effector consists of a cup-shaped component and when it comes into contact with the object to be gripped, vacuum is created in the cup which ensures that the part remains attached. This type of end effector is used for delicate parts. The suction cup is connected by the mounting element to the robot arm. The unit consists of pneumatic or electric unit to generate or remove vacuum, valves and other elements to control the vacuum. A monitoring system ensures safe operation of the unit.

Magnetic Gripper

Magnetic End Effector consists of a permanent magnet that moves in an aluminium cylinder. When the actuator drives the magnet towards the front end of the cylinder, it holds ferrous parts. As the magnet is extracted from the cylinder, the magnetic field fades and the parts are released. This type can be used for only ferrous parts and has the benefit of managing parts with asymmetrical form as well as holding a number of parts concurrently.