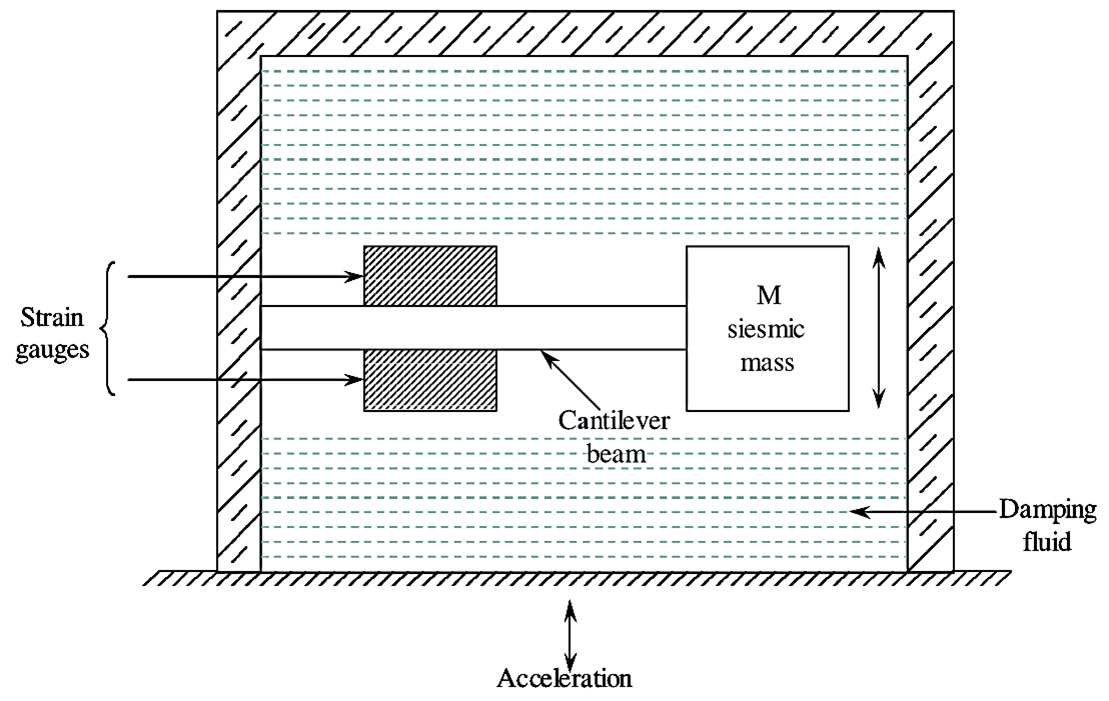

Fig. 1: Strain Gauge Accelerometer.

Working Principle of Strain Gauge Accelerometer

When acceleration to be measured is applied to a cantilever beam whose movable end is attached to a seismic mass, the mass vibrates, which causes the cantilever beam to deflect and get strained. This strain is proportional to the vibrational displacement of the seismic mass and hence the applied acceleration.

Construction and Working of Strain Gauge Accelerometer

A strain gauge accelerometer employs cantilever beam, seismic mass, two bounded strain gauges and damping fluid (see Figure 1). One end of the cantilever beam is attached to the frame of the accelerometer and the other end (movable end) is attached to a seismic mass. Two strain gauges are placed on the cantilever beam nearer to fixed end. Then the housing is filled with some viscous fluid iii order to provide damping.

Now the accelerometer is attached to the device or object whose acceleration is to be known. In the presence of vibration or acceleration vibrational displacement of seismic mass takes place due to which cantilever beam deflects and get strained. When the beam gets strained the strain gauges are also strained (or senses the strain of the beam). Therefore the resistance of the strain gauges will change. This change in resistance is measured by connecting the strain gauges by means of leads in the Wheatstone bridge circuit. The output voltage of the bridge gives the value of change in resistance which in turn gives the value of strain and hence the acceleration or vibration.