Bimetallic thermometers use two fundamental principles:

- All metals expand or contract with change in temperature.

- Temperature coefficients of expansion are not same for all metals and therefore, their rates of expansion or contraction are different. This property of difference in rates of thermal expansion is used to produce deflections proportional to temperature changes.

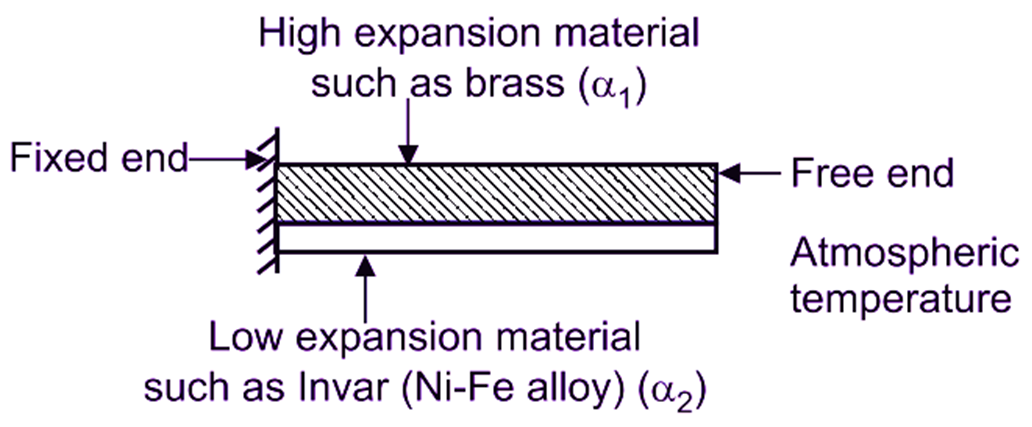

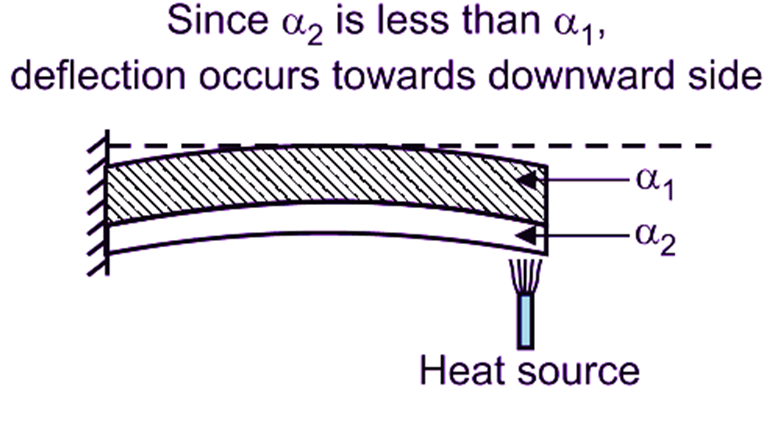

A bimetallic thermometer consists of a bimetallic strip, which is constructed by bonding together with two thin strips of two different meta s, such that, they cannot move relative to each other. Bimetallic strips can be arranged in various forms like flat, spiral and single helix and multiple helix configurations. As the temperature applied to the strip increases, there will be deflection of free end of strip. Length of both metals will change according to their individual coefficient of thermal expansion. Let ‘a’ be the notation used for coefficient of thermal expansion. As one end of bimetallic strip is fixed, the strip will bend at free end, but towards the side of metal having low coefficient of thermal expansion. Reverse will happen, if there is decrease in temperature. Deflection of free end is directly proportional to two quantities,

- Square of length of metal strip and,

- Change in temperature.

Fg. 1 shows a bimetallic strip in the form of a straight cantilever beam. With one end fixed, the temperature change causes the free end to deflect.

(a)

(b)

Fig. 1: Plain Bimetallic Thermometer (a) Atmospheric condition, (b) A heat source is placed at free end

Factors Affecting the Response of Temperature Sensing Element of Bimetallic Thermometer

- Values of heat transfer coefficient.

- Thermal conductivity of temperature sensing element, whether low or high.

- Change in physical dimensions due to change in temperature may have an adverse effects on measured reading and accuracy of measuring instruments.

- Surface area per unit mass of temperature sensing element.

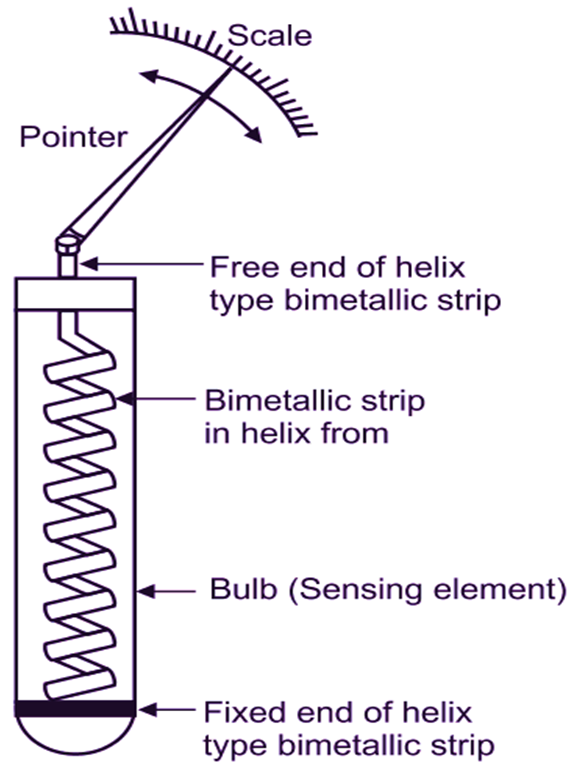

HELIX BIMETALLIC THERMOMETER

Operating Range: 30°C to 300°C

Fig. 2 Shows Helix bimetallic thermometer, in which, a bimetallic strip is wound in the form of helix. One end of helix is fastened to the casing of bulb and another end is connected to pointer. When the bimetallic helix is heated, difference in thermal expansion of metals causes it to unwound. Due to this, pointer moves or sweeps over a circular scale to indicate the measured value of temperature.

Fig. 2: Helix Bimetallic Thermometer

Applications of Helix Type Bimetallic Thermometer

- Used in industries to measure temperature.

- Used in refineries, hot tanks, hot water heaters etc.

Advantages of Helix or Spiral Type

Bimetallic Thermometer over Plain Bimetallic Thermometer plain Bimetallic Thermometer is unsuitable for use in industrial applications due to following reasons,

- Less deflection of pointer, and

- Low sensitivity.

In case of Plain Bimetallic Thermometer, deflection of pointer is very small and limited due to small length of bimetallic strip used. This is because deflection of free end is directly proportional to square of length of metal strip. i.e. 1-2. Therefore, to have more deflection and to measure high temperatures, length of bimetallic strip needs to be increased considerably. But, such a longer plain bimetallic thermometer will occupy more space and its practical use is not feasible. This difficulty is overcome in case of helix or spiral type bimetallic thermometers.

Sensitivity can be increased by increasing the length of strip. Therefore, if the required length of strip is too long, then it can be shaped to a spiral or helix form, so that, the instrument will be compact in size. This arrangement permits a very long length of strip to be contained into a fairly small space.

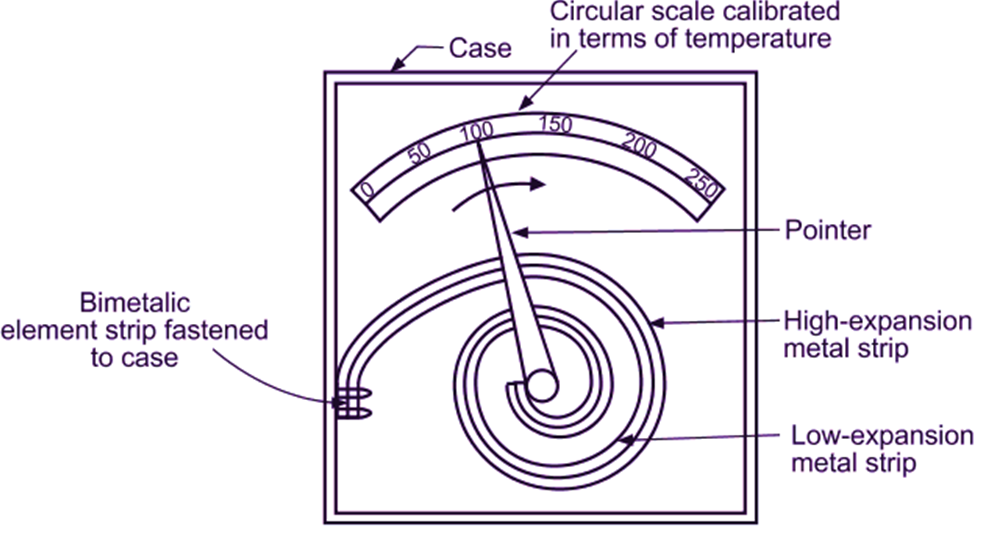

SPIRAL BIMETALLIC THERMOMETER

Operating Range: 30°C to 550°C

Fig. 3 shows a spiral bimetallic thermometer instrument. Here, the spiral bimetallic (strip) element is attached to the pointer mounted in housing with a scale. When the spiral bimetal is heated, it bends in the direction of metal having ow thermal coefficient of expansion, and rotates in clockwise direction. Thus, the pointer attached to it also moves on calibrated scale, indicating the temperature reading.

Fig. 3 Spiral Bimetallic Thermometer Instrument

Applications of Spiral Bimetallic Thermometer Instrument

- Homes and offices for measuring ambient air temperature.

- Commercial and Industrial applications.

Advantages of Bimetallic Thermometers

- Low cost.

- Easy to install and maintain.

- Good accuracy up to ± 0.5

- Wide temperature range.

- Ability to withstand, if subjected to a higher temperature, which is 1.5 times more than the design temperature, for which, it is manufactured.

- Not easily broken.

- Simple and compact instrument.

- Robust construction.

Disadvantages of Bimetallic Thermometers

- Bimetallic thermometers do not have ability to measure temperatures, which are rapidly changing. Therefore, they are not recommended to use for measurements of fast-changing temperatures.

- Materials of bimetallic thermometers may be subjected to permanent deformation or distortion, due to which, they may not be restored to original dimensions. Under such conditions, temperatures measured and indicated may be wrong or incorrect.

- Low speed of response.

Applications of Bimetallic Thermometers

- ON or OFF type thermostats.

- Temperature control systems.

- Control switches in domestic ovens, electric irons, refrigerator etc.

- Industrial applications, such as, refineries, oil burners etc.

- Lamp flashers.

- Time delay circuits.