In this topic, you study the theory and diagram of Controlling Force or Torque in Indicating Instruments.

Controlling force or torque is required:

- To stop the moving pointer at the required position on the scale. If there is no controlling force, the pointer will go on moving. The pointer stops, when controlling torque equals the deflecting torque.

- To bring back the pointer to its zero position, when the deflecting torque is removed. Note that controlling torque acts in opposite direction to the deflecting torque.

The system producing controlling torque is called the “control system” of the instrument.

Production of Controlling Torque

Two methods are used to provide the controlling torque.

- Spring control,

- Gravity control.

Spring Control

In this method two springs of phosphor bronze (Cu = 85

The control torque depends upon the twisting of the springs. The twisting (or stretching) force of the spring is proportional to the angle (θ) through which the pointer moves. In order to avoid angular displacement the spring is made of many turns. The springs provide necessary torque. In addition they are also used to provide electrical connections to the instrument.

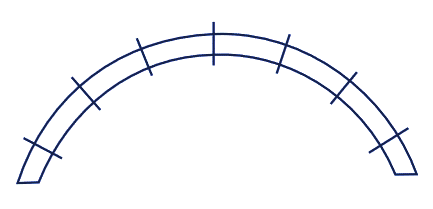

Fig. 1. Spring Control.

When the instrument is not in use. the two springs are in natural condition and controlling torque is zero. However, when deflecting torque (Td) is produced and the pointer moves. one of the springs gets twisted while the other is unwound. The resultant twist produces the controlling torque (TC). The twist goes on increasing with increase in the deflection and so does the controlling torque. The position. when the two torques become equal (Td = TC ) the pointer stops. If the controlling torque is represented by Tc and the pointer’s deflection by θ, we can write down. See Fig. 1.

TC ∝ θ

The pointer stops on the scale when

TC = Td

The deflection is proportional to current I, i.e.

Td ∝ I ∝ θ

Design of Spring: Usually flat springs are used as the space required by these is less. For the flat spring, the controlling torque developed is equal to.

where,

E = young modulus of spring material in N/m2

b = width of spring in m

t = thickness of spring in m

θ = deflection of the pointer in redians

l = length of spring in m

As E, b, t, and l are constants

TC ∝ K θ

where K is another constant called “spring constant.

Note that for design of spring :

- The ratio of length to thickness of the spring (l / t) should be about 2500 so that the spring is not overstressed.

- The fatigue of the spring may be reduced by proper annealing and ageing.

- To eliminate the effect of temperature changes on the length of the springs two springs coiled in opposite directions may be used when one spring is unwound, the other is twisted.

Advantages of Spring Control

(a) The instrument may be placed in any position, i.e., horizontal as well vertical.

(b) As the springs have negligible weight there is no increase in weight of the instrument.

Fig. 2. Uniform Scale.

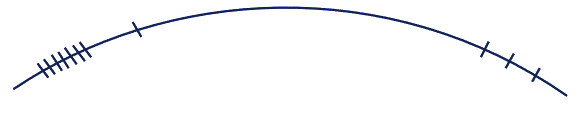

(c) The permanent magnet moving coil (PMMC) spring controlled instruments have a uniform scale (Because Td ∝ I). See Fig. 2.

Disadvantages of Spring Control

(a) Inspite of good design, the change of temperature effects the length of the springs and also the controlling torque.

(b) Due to fatigue, the springs deteriorated with time and hence accuracy is lost.

Gravity Control

In this method, the principle of natural downward pull due to gravity is employed. A small weight W is placed on an arm attached to the moving system. The position of the weight may be adjusted according to the need. This moving weight produces the necessary controlling torque.

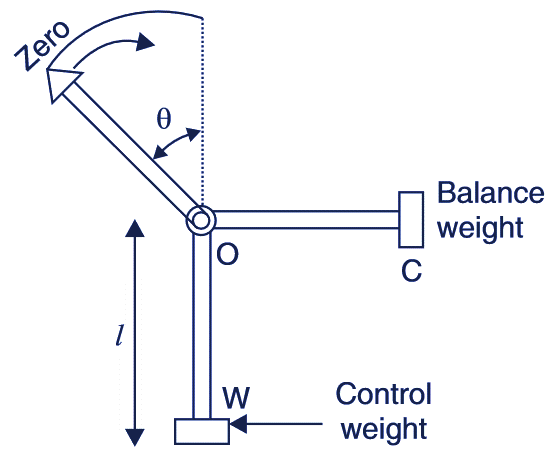

At zero position of the pointer. the control weight W is in the vertical position and therefore no controlling torque is produced. However under the action of the deflecting torque. the pointer deflects through an angle 0 from its zero position as shown in Fig 3. When pointer moves from A to B the weight moves from C to D Fig. 4. But due to gravity, the control weight would try to come back to its original vertical position and produces the necessary controlling torque. The pointer stops when the controlling torque becomes equal to the deflating torque, ie.

TC = Td

Fig. 3. Gravity Control

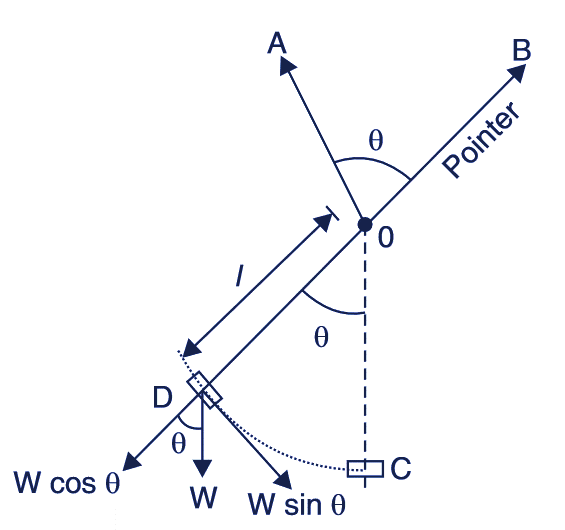

The Fig, 4. shows that the pointer deflects through an angle θ and so the control weight. The two components of the deflected weight will be W Cos θ and W Sin θ, only the component W Sin θ provides the controlling torque and helps to restore its original vertical position, i.e. Controlling torque,

TC = W Sin θ × l = W l Sin θ

or TC ∝ W Sin θ, as W and l are constants. Hence the controlling torque is proportional to the sine of the angle of deflection of the moving system and also therefore scale of a gravity instrument will not be uniform; but crowded generally in the beginning. See Fig. 5.

Fig. 4. Effect of Gravity Control.

Fig. 5. Non-uniform Scale.

Advantages of Gravity Control

- It is a simple and cheap method.

- It is not affected by temperature changes.

- It is free from fatigue.

- By adjustment of the weight, controlling torque can be varied.

Disadvantages of Gravity Controlled Instruments

- These have a non uniform scale and thus readings become difficult.

- The instrument must be kept always in vertical position and hence they are not portable and their use is limited for indoors, otherwise there will be a serious error.

- The control weight adds to the weight of the instrument. It decreases the torque weight ratio and reduces sensitivity of the instrument,

Due to these reasons. gravity control is not suited for indicating instruments in general and portable instruments in particular. The system is obsolete now.