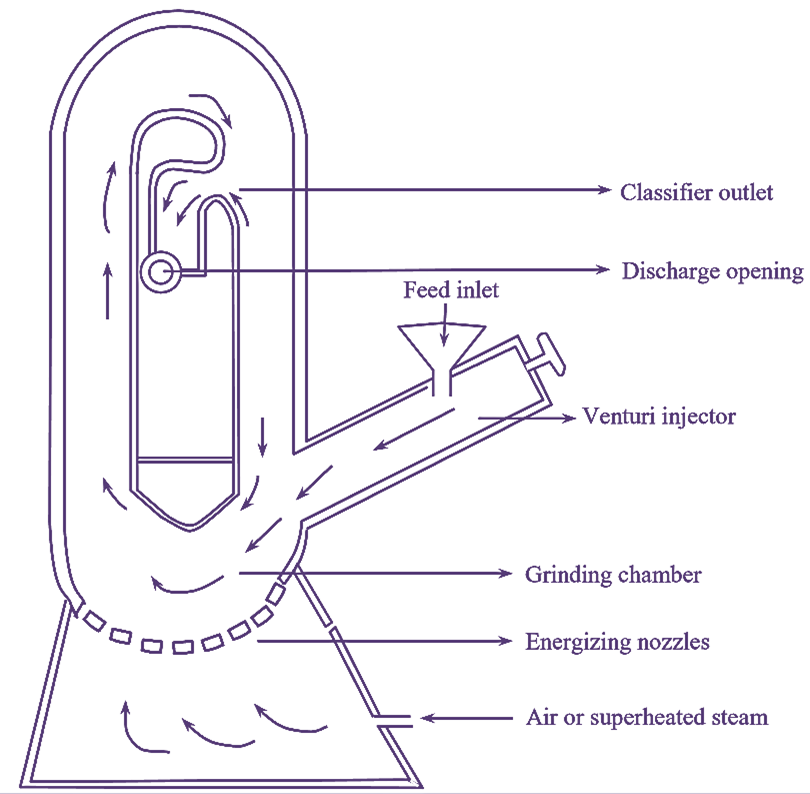

Figure: Fluid Energy Mill.

Fluid Energy Mill is used for ultrafine dry grinding and is suitable for thermolabile substances.

Working Principle of Fluid Energy Mill

Fluid energy mill is also known as jet mill. It works on the principle of impact and interparticle attrition to achieve the desired particle size.

Construction of Fluid Energy Mill

It consists of a grinding chamber which is an oval loop of pipe. It has a diameter of about 25-200 m and its height is 1.2-2.4 m. A feed hopper is attached near the bottom of the oval loop, with a venturi injector in between. At the bottom of the oval loop, energizing nozzles are arranged which suspend compressed air or superheated steam at a pressure of 7 atm. There is a bend at the upper side of the loop. Towards the inner side of the bend, a discharge opening is present, which ends in a cyclone separator. A product collector is attached to the cyclone separator.

Working of Fluid Energy Mill

Feed from the hopper passes through the venturi injector and enters the grinding chamber. Energizing nozzles suspend air or superheated steam at a pressure of 7 atm in the grinding chamber. Due to this, the feed particles experience an impact when they strike against the walls of the grinding chamber. This accounts for some of the particle size reduction due to the collision of particles with each other. Particles get segregated at the bend due to the swirl generated by the high speed of air stream, where oversized particles are thrown against the outer wall and finer particles are thrown at the inner wall of the loop. Finer particles are discharged through the discharge opening into the cyclone separator, where the product is separated from the dust particles and is collected in the product collector. Up to 6000 kg of feed can be milled per hour. Oversized particles undergo recirculation in the grinding chamber until they are sufficiently reduced and leave the chamber via the discharge opening.

Advantages of Fluid Energy Mill

- Feed particles are easily size reduced to ultra-fine particles of 30 mm or lesser in size.

- It is a fast process and up to 6000 kg of feed is milled per hour.

- Thermolabile substances like antibiotics, enzymes, hormones, vitamins etc., can be easily milled as the milling process does not produce heat.

- The mill lacks moving parts, hence, there is no abrasion of the mill and therefore no contamination of the feed.

- Surface of the product particles are smoother and less angular in shape than by other methods.

- Repeated micronizing of feed produces finer particles of spherical shape.

- Size reduction of very sensitive materials can be earned out by the use of inert gases.

- Other than size reduction, the mill may also be used for dehydration of wet feed.

- The mill is of immense help in the size reduction of poorly water-soluble compounds.

- All the components of the mill that are in touch with the product are made up of stainless steel. This helps in maintaining quality as per pharmaceutical requirements.

- Cleaning of the mill is easy.

Disadvantages of Fluid Energy Mill

- The mill is expensive.

- Premilling of the feed is required.

- Soft and fibrous materials are not size reduced with ease.

- Heavy particles or particles with larger diameters need successive milling operations.

- The process requires higher pressures that in turn need more gaseous fluid.

- Energy consumption is very high.

Applications of Fluid Energy Mill

- Non-sticky solids are size reduced.

- Heat-sensitive substances like antibiotics and vitamins are size reduced.

- Hard materials are size reduced.