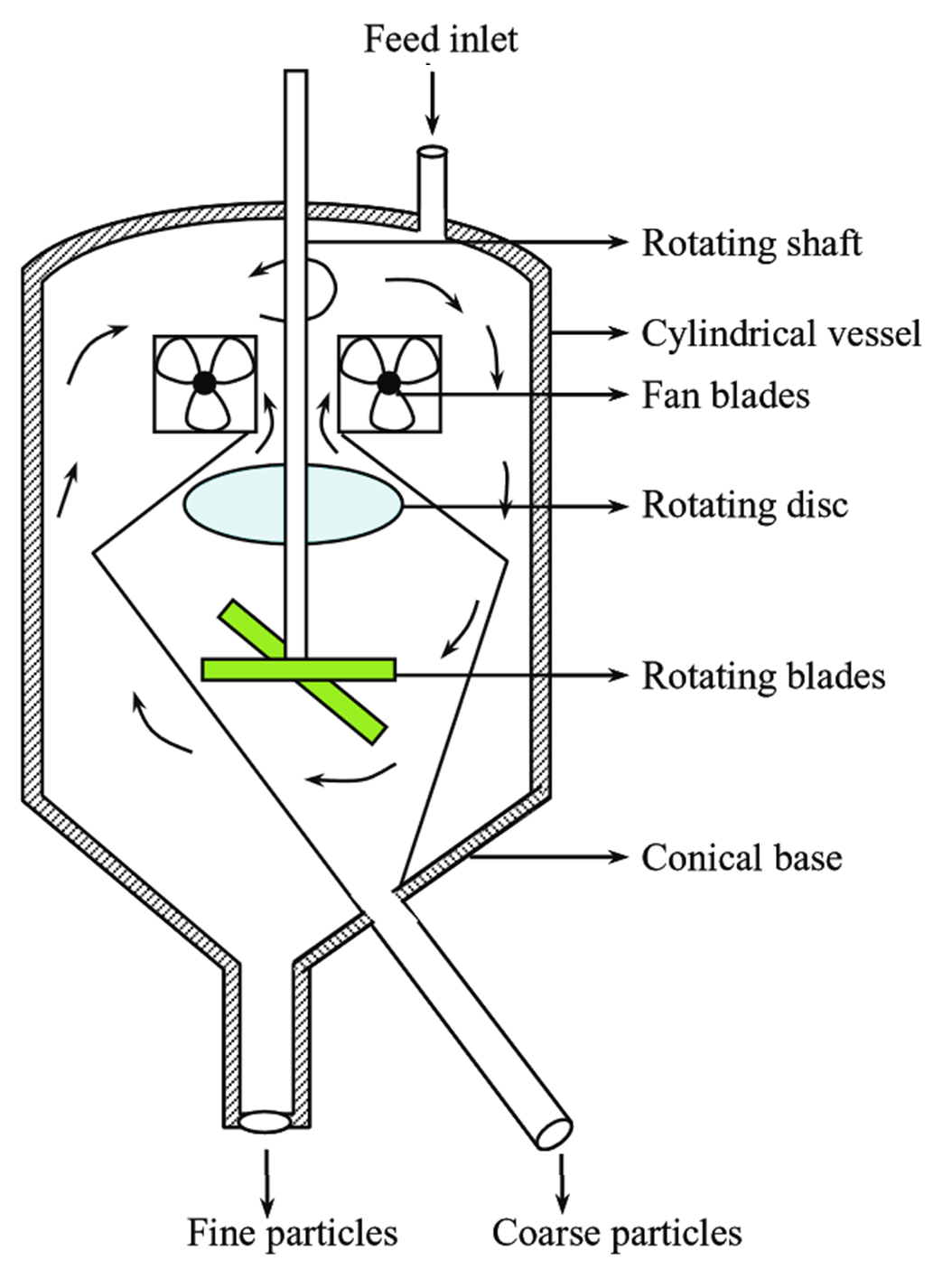

Figure 1: Air Separator.

Working Principle of Air Separator

Air separator works on the same principle as that of the cyclone separator. In this equipment, air current and centrifugal force are used in combination to enable the separation of particles.

Construction of Air Separator

Air separator consists of a cylindrical vessel tapered at the base (see Figure 1). A central shaft with rotating disc and blades is present at the centre of the vessel which is rotated by means of a motor. The equipment also consists of a set of fan blades to produce a current of air. Feed is introduced into the vessel by means of feed inlet provided at the upper portion of the vessel. The conical base is provided with two outlets, one for fines and the other for coarse particles.

Working of Air Separator

Inside the cylindrical vessel, air current and centrifugal force is produced by means of fan blades and motor driven central shaft with rotating disks and blades respectively. Once the feed is admitted into the air separator through the feed inlet, it falls on the rotating disk. Speed of rotation can be controlled in order to separate the particles of definite size. As the blades rotate, the particles also rotate along with the blades. Fine particles are carried by the air and once the velocity of air is reduced, these particles fall at the conical base and are collected through the outlet. Coarse particles fall downwards as they are too heavy to be picked by air stream and are collected from a separate outlet.

Applications of Air Separator

- Air separators are used for the separation of fine particles.

- The equipment can be attached to a ball mill or hammer mill. Oversized particles are separated by means of air separator and returned to the size reduction equipment for further size reduction.