In this topic, you study the theory and diagram of Fluid Friction Damping.

This damping is similar to air friction damping except that air is replaced by a high viscosity oil.

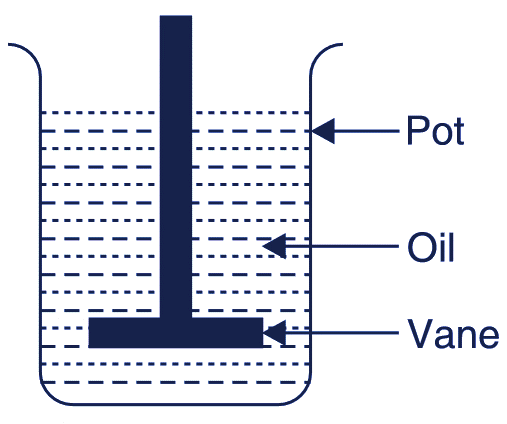

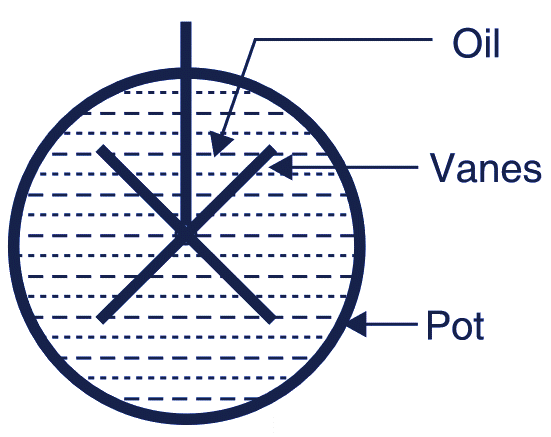

In this method one disc Fig. 1 (a) or more than one wanes Fig 1 (b) are attached with the spindle of the instrument. When the system moves, a frictional force is produced, which is in opposition to the motion and thus checks the movement. The damping torque can be increased by :

- Using high viscosity oil.

- Using more discs or vanes.

(a)

(b)

Fig. 1. Fluid Friction Damping.

Advantages of Fluid Friction Damping

Fluid friction damping has an advantage that the oil can be used for damping as in oil. It does not need care as for the air friction method, as clearance between wanes and the walls of the oil pot has no effect on the working of the instrument. This method is suited for electrostatic instruments, where the movement is suspended rather pivoted.

Disadvantages of Fluid Friction Damping

- This method is not suitable for portable instruments because the oil may over now or spill out.

- For the same reason, the instrument must be used always in the vertical position.

- The “creeping” of oil affects the accuracy of the instrument. Moreover, the instrument cannot be kept clear and it will affect its sensitivity.