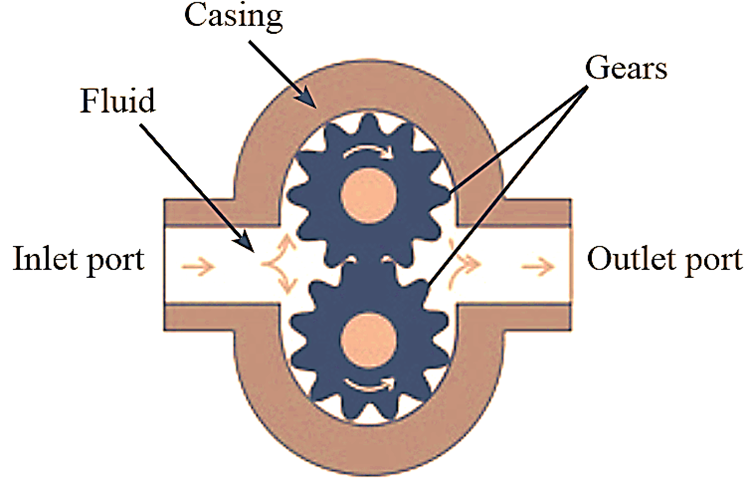

Gear pump is the positive displacement pump in which the suction is created by rotation and meshing of two gears. The fluid enters into the pump through the inlet and is transferred through the outlet port. It pumps the hydraulic fluid through two similar inter meshing spur gears, mounted in a casing, by displacement.

Figure 1: Gear Pump.

Types of Gear Pump

Based on the arrangement of gears, gear pumps are classified into two types. They are,

- External gear pump

- Internal gear pump.

External Gear Pump

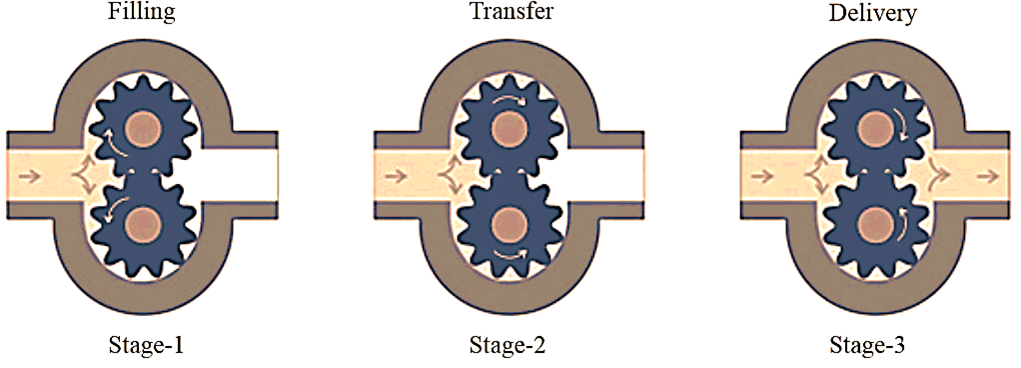

Figure 2: External Gear Pump.

In this type of gear pump, two similar gears mesh externally and are rotated in opposite direction. One of the gears is known as driver gear and is connected to a electric motor. Whereas, the other gear is known as driven gear, which is in constant mesh with the driver gear.

Working of External Gear Pump

The working of external gear pump consists of three stages (Figure 3),

Stage-1: When the gears start rotating and are in mesh, a suction pressure is created at the inlet port. This allows the fluid to enter into the pump. At inlet of the pump, the rotation of gears causes the teeth out of mesh i.e., the teeth starts coming out of meshing (disengaging). This enhances the volume expansion of fluid and also reduces the pressure less than the atmospheric pressure.

Stage-2: Due to the continuous rotation of the gears, the fluid is transferred to the discharge side. The fluid moves through the gear teeth and housing of the pump and finally to the discharge end.

Stage-3: At the discharge end, the gear teeth comes into mesh. Therefore, the volume is decreased and the pressure is increased such that the fluid is forced out of the pump.

Advantages of External Gear Pump

- These pumps are bi-directional i.e., direction of the flow can be changed by changing the direction.

- Very compact

- Less weight

- High volumetric efficiency

- Constant discharge is maintained for a given speed

- It has the ability of self priming.

Disadvantages of External Gear Pump

- Liquids should be free from dust and dirt i.e., they should be clean.

- Requires relief valves.

- Pumping rate can be changed using variable speed drives.

Why gear pumps cannot be used as a variable displacement pump?

There is no chance of changing the design parameters in the gear pump after finalizing the gear pair dimensions. Therefore, the displacement cannot be changed and it cannot be used as a variable displacement pump.