Horn gap arrester is used at limited places due to its unreliability i.e. it is used as backup protection with the main arrestor.

Construction of Horn Gap Arrester

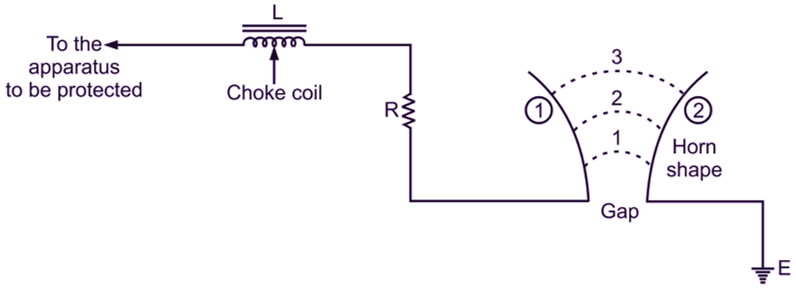

As shown in Fig. 1, (1) and (2) are the rods bent to give horn like construction with the air gap in between the shape of horns widening on the top portion and narrow at the bottom portion. The horns are supported on the insulating base of porcelain. As shown in Fig. 1, one horn connection goes to the apparatus to be protected through a resistance ‘R’ and a choking coil ‘L’. The second horn connection goes to the ground for earth connection. The resistance ‘R’ plays an important part in the circuit. It helps in limiting to follow current to a small value. Inductance of chock coil ‘L’ also helps and protects the equipment by providing high reactance (XL = 2πfL) where f is the transient frequency which is very high. At normal frequency the reactance XL = 2πfL is small as f is only 50 Hz. Hence, chock coil does not allow the transients to enter the apparatus to be protected.

Fig. 1: Horn Gap Arrester

Working of Horn Gap Arrester

The gap between the horns is so adjusted that normal voltage and frequency does not produce arc between the horns. The gap acts as an insulating media. But when over voltage occurs due to surges or transients, the voltage is sufficient to break the insulation of the air-gap and spark (arc) is produced. The air in the gap is heated up and hence goes up and speeded up due to magnetic effect as shown in Fig. 1 the arc moves in stage 1, stage 2 and 3. At position 3, the distance is much more and the surge voltage cannot maintain the arc and it vanishes and normal condition is brought into the circuit. This way the equipment is protected from a voltage surge. The excess charge is conducted through portion 2 of the horn and goes to earth.

Advantages of Horn Gap Arrester

- This is superior than rod-type because arc is self clearing and no chance of short circuit.

- R and L limits the current to small values.

Drawbacks/Limitations of Horn Gap Arrester

- Time of operation is about 2 to 3 seconds, hence not reliable.

- Some materials or birds may fall in the horn gap creating troubles.

- Due to long use, corrosion and pitting takes place, hence setting between the horns for proper air-gap is disturbed and hence performance is affected.

Uses of Horn Gap Arrester

As said earlier its uses are limited due to unreliability and are used for backup protection with the main arrester.