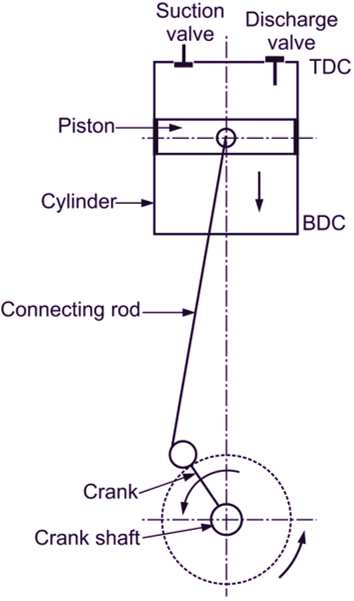

Reciprocating compressor may be defined as, “the compressors, in which, the vapour refrigerant is compressed by the reciprocating motion of piston (back and forth) “. Fig. 1. shows a single stage single acting reciprocating compressor. To prevent the piston from striking the valve plates, all reciprocating compressors are designed with a small amount of clearance between the top of the piston and the valve plate, when the piston is at the top dead center (top of its stroke). The volume of this clearance space is called as clearance volume.

Clearance volume is defined as, “the volume of cylinder, when piston is at top dead centre position”. The vapour refrigerant, which remains in the clearance space at the end of each discharge stroke, is called as clearance vapour.

Fig. 1: Reciprocating air compressor

Working of Reciprocating Compressor

Let us consider that, the piston is at top dead centre position. Refer Fig. 1.

Suction stroke

When the piston is at TDC, both, the suction and discharge valves are closed. The suction valve is held closed, because of the high pressure of the compressed vapour refrigerant trapped in the clearance space, in the previous cycle. This high pressure acts in upward direction on the suction valve, keeping it closed. On the other hand, the discharge valve is held closed either by its own weight or by spring pressure. When the piston moves downward from TDC towards BDC (i.e. during suction stroke), the high pressure vapour refrigerant trapped in the clearance space expands. Thus, the volume of cylinder (above the piston) increases and pressure inside the cylinder decreases. When the pressure inside the cylinder becomes slightly less than the suction pressure or atmospheric pressure, the suction valve gets opened and the vapour refrigerant flows into the cylinder. This flow of refrigerant through suction valve in to the cylinder (i.e. suction of vapour refrigerant) continues till the piston reaches bottom dead center position. This completes suction stroke.

Compression stroke

Now, when the piston moves from BDC towards TDC, i.e. in upward direction, the volume inside cylinder (above the piston) decreases and pressure inside the cylinder increases up to a set value, so that, it can overcome the spring pressure acting on the top of discharge valve. Now, discharge valve gets opened and compressed vapour refrigerant is discharged into the condenser. Thus, vapour compression cycle continues further.

Applications of Reciprocatin Compressor

- Reciprocating compressor is most Widely used type Of compressor, being employed in almost all fields of refrigeration.

- Reciprocating compressor is used with refrigerants, which require relatively small displacement and gets condensed at relatively high pressures.

- Reciprocating compressors are suitable for refrigerants such as R-12, R-22, R-500, R-502 and R-717 (ammonia).

- Reciprocating compressor has been used very successfully in both low temperature as well as ultra-low temperature installations.

- Reciprocating compressors are available in sizes ranging from 9 W in small sized domestic units to around 1000 kW or more in large industrial installations.

- Due to availability in wide range of sizes and designs along with good durability and efficiency under a wide variety of operating conditions, reciprocating compressors are popular in the field of refrigeration.

Single Acting and Double Acting Reciprocating Compressor

Reciprocating compressors may be either single acting or double acting. In single acting compressors, compression of vapour refrigerant occurs only on one side of the piston and only once during each revolution of crankshaft, whereas, in double acting compressors, compression of vapour occurs alternately on both sides of the piston and thus, compression occurs twice during each revolution of crankshaft. Single acting compressors are used now-a-days for all refrigeration applications.