Operating Range: – 150°C to 300°C.

- The term “thermistor” means Thermal-Resistor.

- It is also called as, “Thermally Sensitive Variable Resistor”.

Working Principle of Thermistor

Thermistors work on following principles.

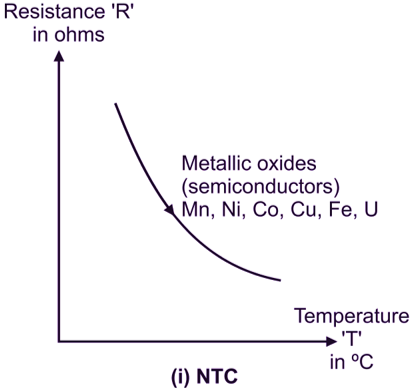

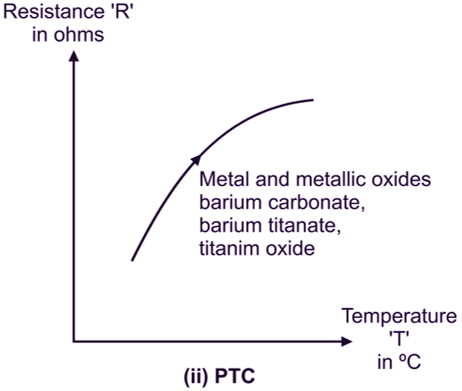

- Negative temperature coefficient (NTC), where resistance of material decreases with increase in temperature. Materials possessing the property “NTC” are composed of metallic oxides (semiconductors) such as, Manganese, Nickel, Cobalt, Copper, Iron and Uranium.

- Positive temperature coefficient (PTC), where resistance of material increases with increase in temperature. Materials possessing the property “PTC” are composed of metals and metal oxides, such as, powdered Barium Carbonate, Barium Titanate and Titanium Oxide. In both cases, relationship of Temperature Versus Resistance is non-linear, i.e. exponential.

Fig. 1: Working Principle Of Thermistors

Construction of Thermistor

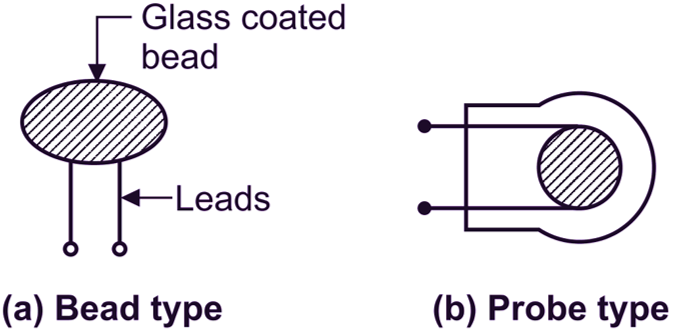

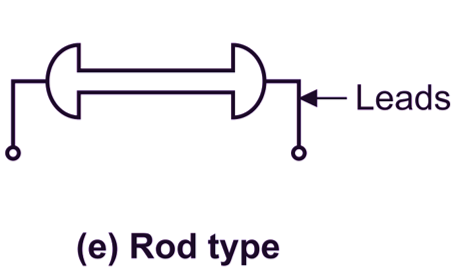

Thermistors working on the principle of NTC are preferred in industrial applications. Thermistor working on the principle of NTC is also called as “Temperature Sensitive Semiconductor”. Thermistors of NTC type are made up of semiconductor materials. They are manufactured by sintering the mixtures of metallic oxides, such as Manganese, Nickel, Cobalt, Copper and Uranium. These metallic oxides are mixed in suitable proportions with binders and compressed into desired shapes and sizes. Therefore, thermistors are available in various sizes and shapes to suit any particular application. Thermistors have lead for connectivity with circuits. Fg. 2 shows various forms or shapes of thermistors, such as, bead, probe, disk, rod, washer type etc.

Bead type thermistor

Bead type thermistor is smallest in size having diameter in the range of 0.01 mm to 1.2 mm. Bead type thermistor is sealed in the tips of solid glass rods to form probe type thermistor.

Probe type thermistor

Probe type thermistors have diameter 2.5 mm (approx.) and ength in the range of 6 mm to 50 mm.

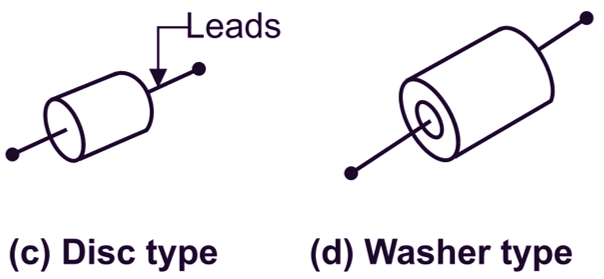

Disc type thermistor

Material used for manufacturing disc type thermistor is pressed under high pressure to obtain it in the form of cylindrical shape having diameters from 2.5 mm to 25 mm. Therefore, a large variety of disc type thermistors having different diameters is available in market. It makes possible to select type of thermistor to suit any particular type of application.

Washer type thermistor

Design of disc type thermistors is modified to obtain washer type thermistors (washer shaped).

Fig. 2: Different Forms of Thermistors

Advantages of Thermistor

- It is more stable.

- Small in size.

- Low cost.

- High sensitivity.

- Fast thermal response.

- Stronger and rigid construction.

- Easily adaptable to electrical read-out devices.

Disadvantages of Thermistor

- It requires external energy source.

- Not suitable for wide range of temperature.

- Need of shielded power lines.

- Cannot be used to measure temperature higher than 300°C.

- Non-linear resistance-temperature relationship.

Applications of Thermistor

- Used as sensor in measurement systems of liquid level, pressure, flow etc.

- Used for measurement of power at high frequency.

- Used for temperature control, temperature compensation and time delay circuits.

- Used for measurement of temperature in Vacuum.

- Used for measurement of temperature of composition of gases.

- Used for measurement of thermal conductivity.

INDUSTRIAL OR PRACTICAL APPLICATIONS OF THERMISTORS

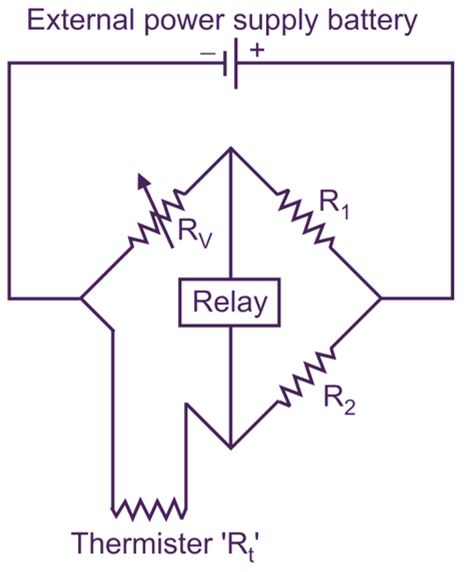

Use of Thermistor for Temperature Control

A sensitive temperature control can be achieved by placing thermistor in one arm of a Wheatstone bridge, a variable resistor in another arm and a polarized relay across the output. Refer Fig. 3. When temperature around the thermistor increases, it becomes warm and operate the relay In one direction. Conversely, when temperature around the thermistor decreases, it becomes cool and operate the relay in opposite direction. Point of temperature control and operation can be changed by changing the value of resistance in variable resistor.

Fig. 3: Use of Thermistor for Temperature

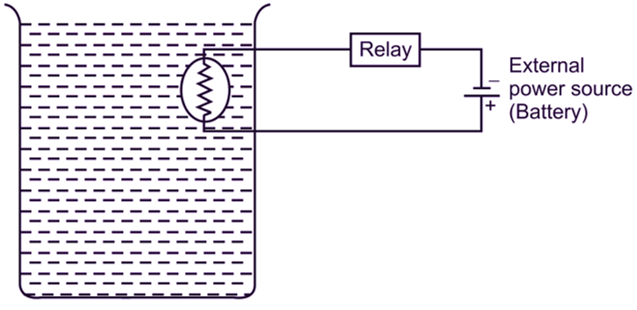

Use of Thermistor for Liquid Level Control

Thermistor can be used as liquid level controller. For this purpose, thermistor is immersed in a liquid tank. Thermistor is connected with a relay and battery as shown in Fig. 4.

Case (i): Liquid level decreases below desired level

When level of liquid decreases below the location of thermistor, then thermistor will be exposed to atmosphere. As thermistor comes in direct contact with atmospheric air, its temperature will increase. Due to increase in temperature, resistance of thermistor will decrease. This will permit enough current to flow through the circuit, and energises the relay to start the liquid pump. Thus, liquid comes in tank and its level rises up to des red level.

Case (ii): Liquid level increases causing overflow

When level of liquid increases, thermistor will be submerged in liquid. Thermistor will be cooled and its temperature will decrease. Due to decrease in temperature, resistance of thermistor will increase. This will reduce the flow of current through the circuit, which makes the relay to stop the liquid pump. This will avoid any possibility of overflow of liquid. Thus, thermistor controls and maintains the desired liquid level in tank.

Fig. 4: Use of Thermistor as Liquid Level Controller

Characteristics of Thermistor

Resistance – Temperature characteristic:

Thermistor follows the relation,

\[{{\text{R}}_{\text{t}}}\text{= a}\text{. }{{\text{e}}^{\text{(b/T)}}}\]

Where, “a” & “b” are constants,

Rt = Resistance of thermistor at absolute temperature “T”.

Voltage – Current characteristic:

If voltage is gradual y increased, the current will increase and the heat generated in thermistor will finally beg n to raise its temperature above surrounding temperature.

Current – Time characteristic:

Current – Time effect provides a simple and accurate way of achieving time delays from milli-seconds to many minutes.