Range: – 2000 to 3000 r.p.m.

Construction of Revolution Counter and Timer

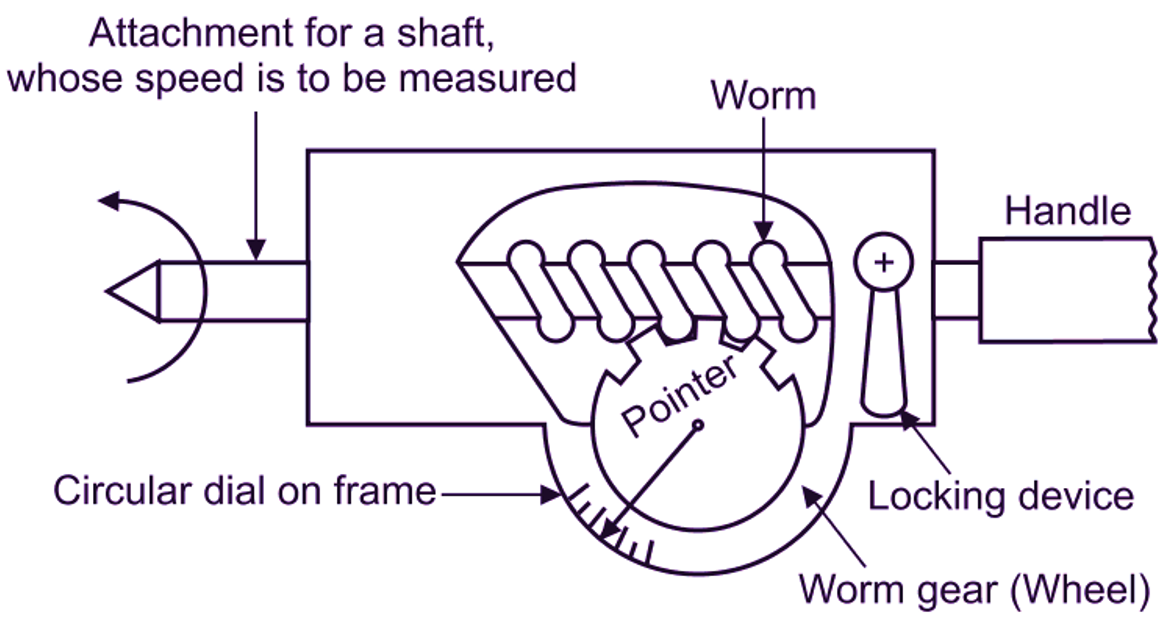

Revolution counter and timer consists of a worm and a worm gear (wheel) in mesh. The shaft, whose speed is to be measured, is connected to worm. When the rotating shaft is engaged hence, it drives or rotates the worm gear (wheel) in mesh. Arrangement is made in such a way that, one revolution of worm causes the worm gear (wheel) to rotate by one tooth. This arrangement employs a timing device, which counts the number of revolutions measured during certain time interval. A pointer is attached to worm gear.

Working of Revolution Counter and Timer

When the rotating shaft drives worm, the worm gear (wheel) starts to rotate. Rotation of worm gear (wheel) actuates the pointer and makes it to move over calibrated dial (scale). Movement of pointer is a measure of shaft speed. This movement of pointer can be directly calibrated to give number of revolutions made by the shaft within a specified time. It is done by using a separate timer and stopwatch. Thus, the revolution counter and timer gives the total number of revolutions over a given time, i.e. average rotational speed rather than an instantaneous rotational speed.

Fig. 1: Revolution Counter and Timer

Advantages of Revolution Counter and Timer

- Simple to operate.

- Simple in construction.

- Mostly used to measure speed of shaft, pulley, gear etc.

Disadvantages of Revolution Counter and Timer

- It is limited to low speed measurements.

- More chances of error.

- It gives average speed, instead of instantaneous speed.

Application of Revolution Counter and Timer

Suitable for speed measurement at definite time intervals, such as, in case of low speed engines.