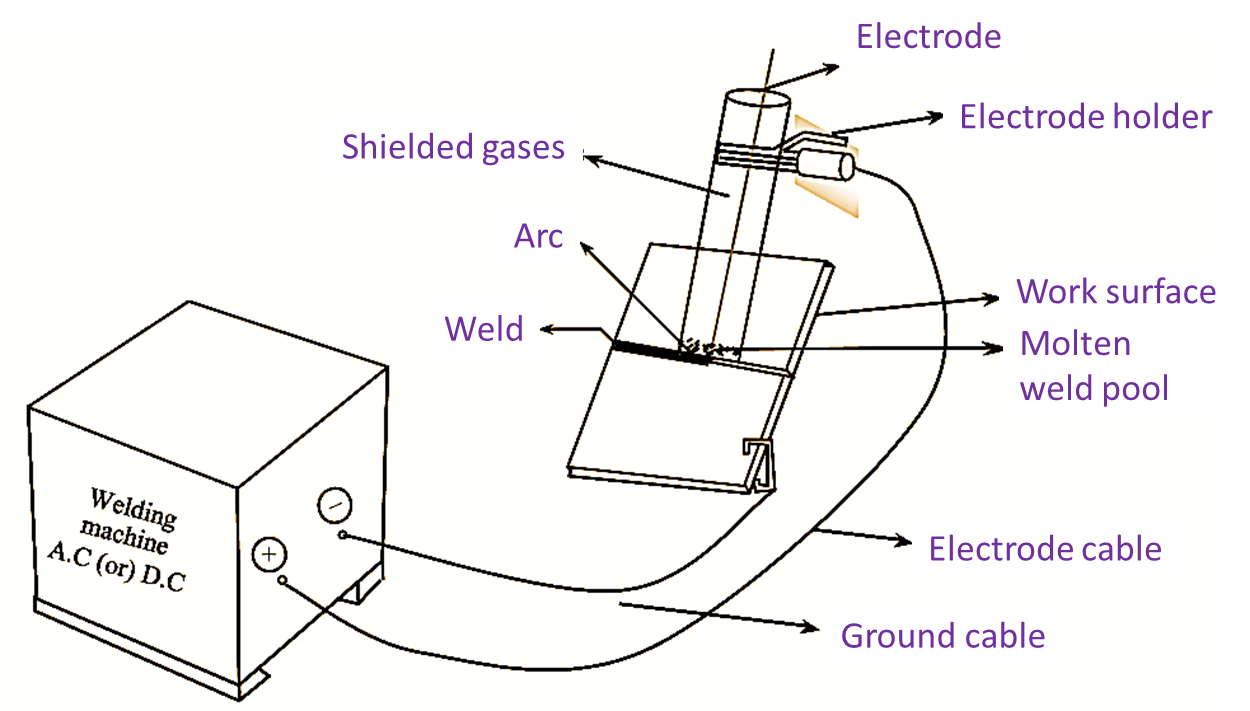

Figure 1: Shielded Metal Arc Welding.

The manual metal arc welding is also known as shielded metal arc welding or metal arc welding process. It is an arc welding process, wherein the welding is done by heating the workpiece with an electric arc set up between a flux coated electrode and the workpiece.

In this type of welding, a metal rod of same metal being welded forms one electrode and serves as a filler rod. Heat required for welding is obtained from the arc struck between a coated electrode and the workpiece. The arc melts the electrode end and the job. Material droplets are transferred from the electrode to the job through the arc and are deposited along the joint to be welded. The electrodes are coated with a covering (flux coated electrodes) to prevent the contamination of molten weld metal, since the flux coating generates a gas shield around the arc, which protects the weld against the foreign matter. Fluxing not only protects the weld but also stabilizes the arc and governs the rate and amount of metal flow in weld. For metal arc welding, both A.C and D.C can be used. However A.C is preferable as compared to D.C since, D.C metal arc welding may result in arc blows.

Advantages of Shielded Metal Arc Welding

- Most of the metals can be welded by this process.

- It can be used for welding at any desired position.

- The equipment used for welding can be easily transported.

- The process is simple and flexible.

Limitations of Shielded Metal Arc Welding

- The filler rod or electrode is to be replaced frequently, which increases the process time.

- Cleaning of slag must be done, after completion of every pass.

- The maximum length over which the weld can be obtained is limited.

Applications of Shielded Metal Arc Welding

- It is commonly employed for welding cast iron, alloy steel and carbon steel.

- Repairing works can be done by using this process.

- Pipes, tanks, cylinders, automobile parts, etc are welded by this method