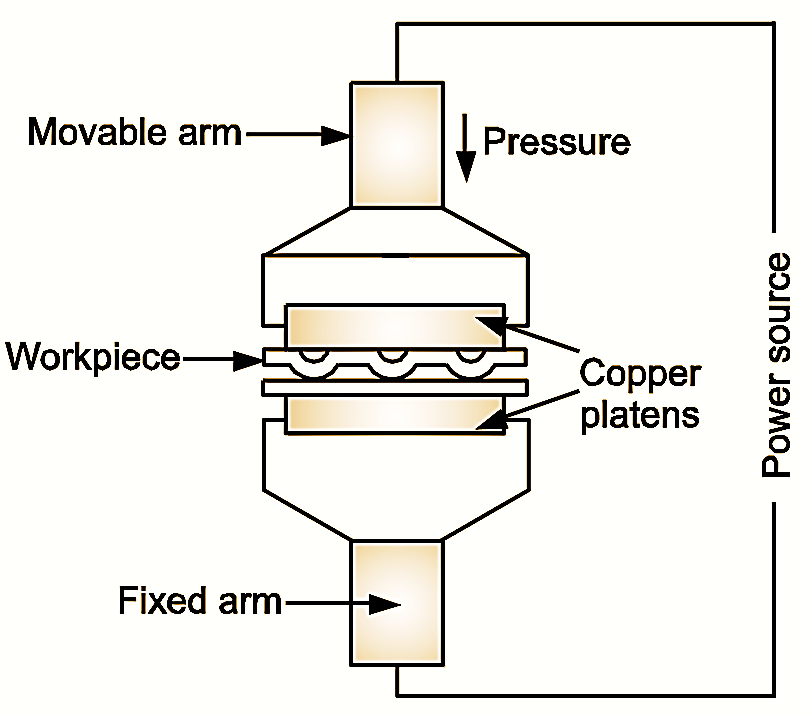

This process is a modification of spot welding, in which the current and pressure are localised at the weld points. In this process, the projections are formed In the sheets to be welded by embossing in a punch press. The welding is done in a press type machine with electrodes in the form of platens which can distribute the current and pressure equally on the sheets. The advantage of this type of welding is that a number of spot welds can be made simultaneously (see Fig. 1).

Fig. 1: Projection Welding.

Electrodes have a longer life, as only flat surfaces of platens are used instead of pointed electrodes as in case of spot welding. Sheet metal parts used in automobile and air planes are welded by this method. However, all metals can not be welded by this process. Brass and copper collapse under pressure and hence can not be projection welded. Current and pressure requirement for this type of welding is heavy.

Advantages of Projection Welding

- Many number of weld joints can be performed at a time.

- Rust, coating, oil etc. are not affected in this welding process.

- Electrode life is longer than spot welding electrode, because it has lesser wire resistance property.

- It has better heat control for different material composition and thickness.

- Welding obtained is uniform and appears better than spot welding.

Limitations of Projection Welding

- The initial cost is high as press type machines are required for this type of welding.

- This process is economical only for large scale production.

- Brass and copper cannot be projection welded.

Applications of Projection Welding

- In sheet metal welding.

- In ship building works.

- In automobile workshop.

- In refrigeration works.