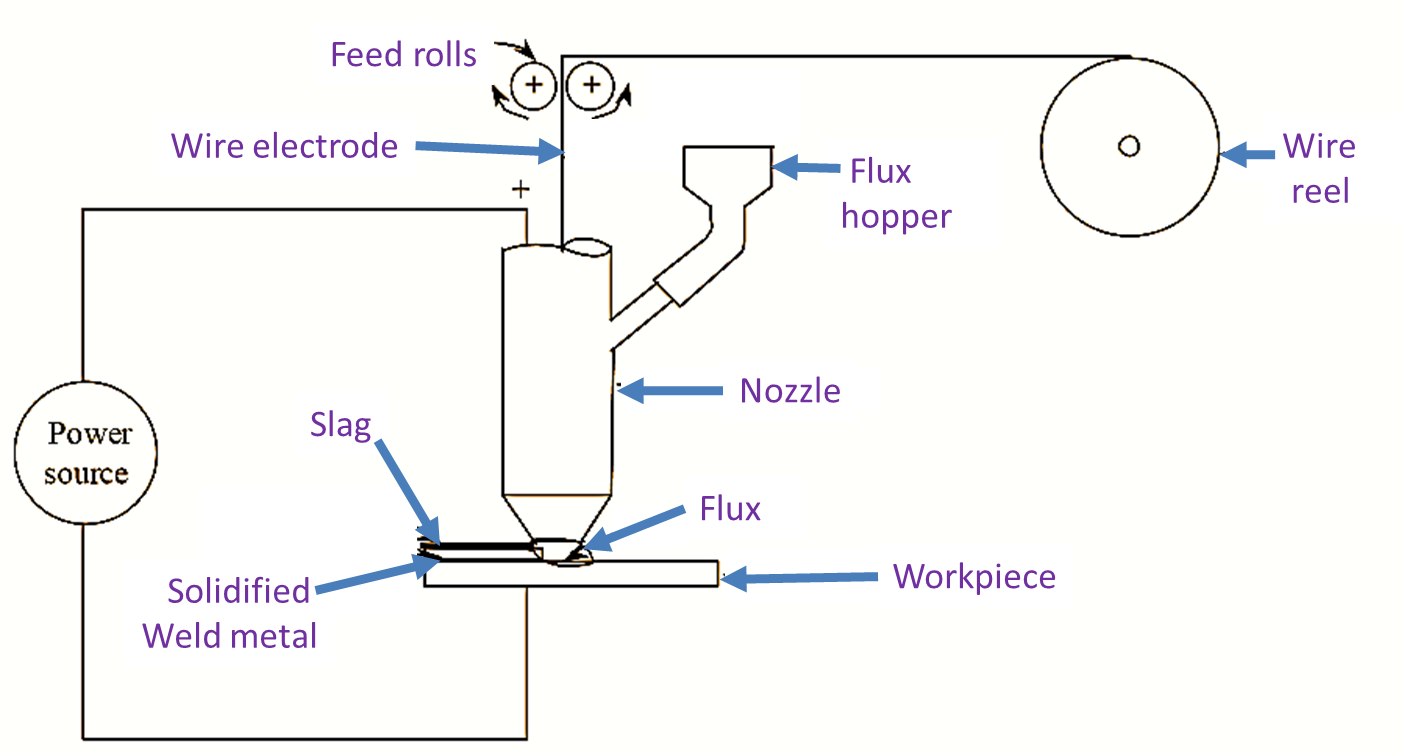

Figure 1: Submerged Arc Welding.

Submerged Arc Welding is used for producing long continuous welding (1.5 – 10 mm) in the form continuous wire is used, a bare consumable metal electrode is used, instead of a coated flux. As the name implies, the arc, end of the electrode and molten weld metal remains submerged under a layer of granular flux, which is fed from a hopper through a nozzle. The wire electrode is fed from a wire reel to the granular flux through feed rolls. A power source is applied between the workpiece and the nozzle. The flux acts as a shield, protecting the molten metal pool from atmospheric contaminations, until it gets cooled, as shown in the following figure.

Advantages of Submerged Arc Welding

- It involves higher welding speeds, which increases the production rate.

- It possess a very high metal deposition rate.

- This process is applicable for both indoor and outdoor welding works.

- It provides consistently high quality welds.

- It requires less operator skills.

- The welding fume and radiation emitted by this process is very less.

Advantages of Submerged Arc Welding

- It is restricted to only flat or horizontal welding position.

- It requires a special attention in aligning the electrode position.

- It is not suitable for welding of metals with less than 5 mm thickness.

Differences between Arc Welding and Submerged Arc Welding

| Arc Welding | Submerged Arc Welding |

| The arc produced is not surrounded. | The arc produced is beneath a layer of flux |

| The process is operated manually | The process can be automated |

| The flux is supplied from coated electrodes | The flux is provided in the form of coarse powder |

| Rate of deposition is low | Rate of deposition is high |

| Penetration is less | It causes deep penetration |

| The quality of weld is not high | The quality of weld is high |

| Slow welding speed | High welding speed |

| Welding of thick plates requires several passes. | Thick plates can be welded in a single pass. |

| Sparks, smoke and flash exists. | Sparks, smoke and flash are eliminated. |

| Poor repeatability | High repeatability |

| Overhead weldings can also be processed | It is restricted only to flat and horizontal welding |

| It can be employed for welding thin and thick sheets | Plates of less than 5 mm thickness cannot be welded. |