Thermocouple vacuum gauge operates on the principle of thermo-dynamics, which states that, “At low pressures, Thermal conductivity (Heat conductivity) decreases with decreasing pressure”.

Due to this property, thermocouple vacuum gauge can measure very low pressures, i.e. vacuum pressure (pressure below atmospheric pressure). Basically, thermocouple vacuum gauge measures the temperature of a heated element, called as heating filament surrounded by residual gas, connected to a vacuum system, whose pressure is to be determined.

Construction of Thermocouple Vacuum Gauge

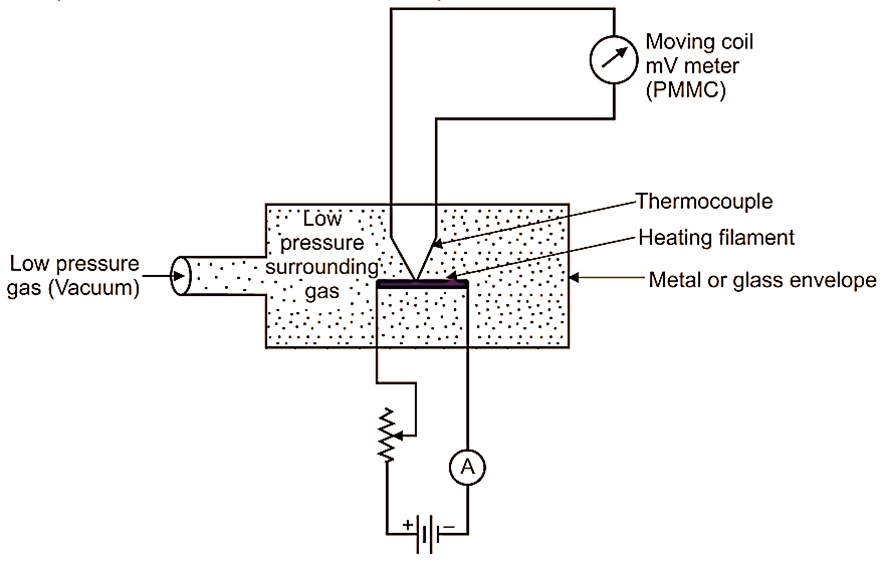

Thermocouple vacuum gauge consists of a heating filament and a thermocouple. Heating filament is in contact with the thermocouple at its centre. The heating filament is a tungsten wire of diameter 0.025 mm. This wire can be heated to a temperature of 50°C to 400°C by a current of 10 to 100 mA, which is known and remains constant. The thermocouple is welded to this heating filament to measure its temperature. Both, Heating filament and Thermocouple are enclosed in a glass or metal envelope. This envelope is connected to the vacuum pressure, which is to be measured.

Fig. 1: Thermocouple Vacuum Gauge

Working of Thermocouple Vacuum Gauge

At a pressure below 1.33 × 106 mm of Hg, the temperature of heating filament is a function of pressure of surrounding gas. Heating filament is heated by a constant current. Therefore, temperature of heating filament will increase. For a given magnitude of current, temperature of heating filament depends upon its rate of heat dissipation to surrounding medium, i.e. gas by means of conduction and convection. After heating, the heating filament is placed or connected to vacuum or low-pressure surrounding gas medium. Now since, the heating filament is surrounded by vacuum or low-pressure gas, thermal conductivity (i.e. ability of heating filament to give away heat to surrounding medium) of heating filament will also decrease. In such conditions, the heating filament will be hotter. We obtain an output voltage reading, which is a function of temperature of heating filament and hence, the function of pressure of surrounding gas. Output voltage of thermocouple is measured by a moving coil (Permanent Magnet Moving Coil, i.e. PMMC), which is directly calibrated to read pressure of the gas.

Conclusion

Higher the gas pressure inside a vacuum system, cooler will be the filament. Conversely, lower the gas pressure inside a vacuum system, hotter will be the filament.

Advantages of Thermocouple Vacuum Gauge

- Rigid construction.

- Cheaper or inexpensive gauge.

- Capable to show readings consistently and continuously.

- Can read very low pressure from 1.33 × 10-6 bar to 1.33 × 10-3 bar (i.e. 0.133 Pa to 13.3 Pa).

- Output can be obtained in digital form.

Limitations of Thermocouple Vacuum Gauge

- Chance of burnout, if exposed to atmospheric pressure.

- Needs individual and frequent calibration for different gases.

- Dependent on electrical power to operate.

- Narrow reading range.

Application of Thermocouple Vacuum Gauge

- Used to measure low pressure of range of 1.33 × 10-6 bar to 1.33 × 10-3 bar.