Investment Moulding process is also known as lost-wax process or precision casting. In this process, expendable pattern of wax polystyrene plastics or frozen mercury is used for making the casting mould. The term investment refers to the refractory mould surrounding the refractory covered wax pattern.

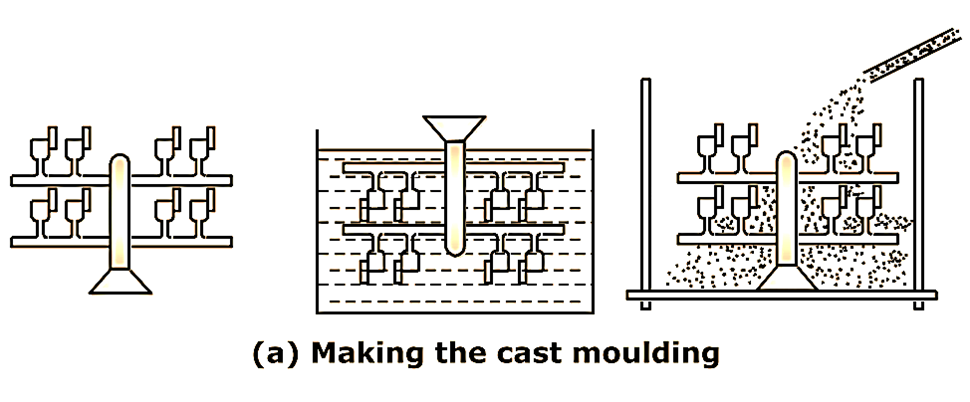

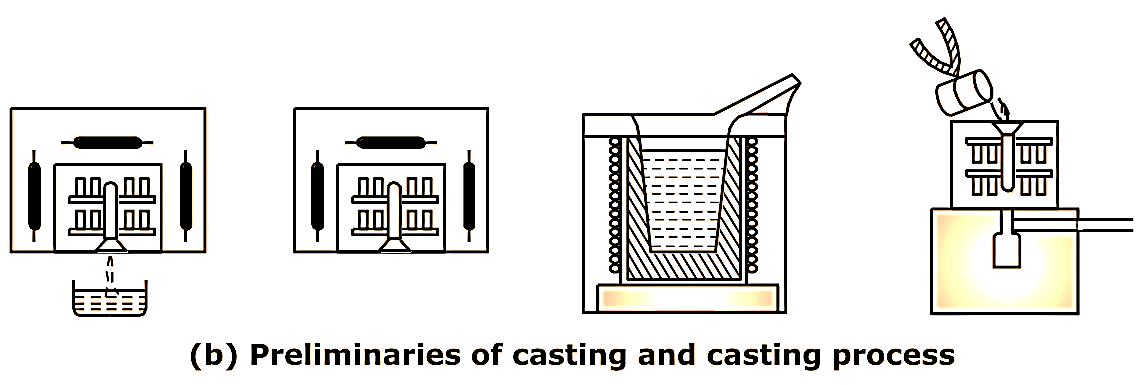

Fig. 1: Investment moulding in stages

In this method, first a die or master mould of metal gelating or alloy of low melting point is prepared from the master pattern. Molten wax or polystyrene plastic is injected into the die under pressure and expendable pattern of wax or plastic is obtained. The injection pressure is used in about 5 N/mm2 for wax and about 90 N/m2 for polystyrene plastics. The wax pattern and gating system are joined together by heating the surfaces to be joined with hot wire. Patterns and gating system of plastics are joined together by moistening the surfaces to be joined with solvent like carbon tetrachloride. This expendable pattern is then used to prepare the casting mould. This pattern is coated with slurry consisting of silica flour and small amount of kaolin and graphite are mixed in water. After this, coarse sand is shaken over the pattern. The sand adheres to the wet slurry and builds up a quartz shell.

The pattern is then used in conventional sand mould but it is not withdrawn. This is the reason why a high precision is obtained in this casting method. The mould is dried in air; then preheated in an oven till the wax melts and flows out through sprue. The mould is then reheated to about 1000°C to improve its resistivity and finally cooled down to temperature desirable for casting the particular metal or alloy. This method is used to cast turbine blades, automobile, sewing machine parts etc.

Advantages of Investment Casting

- Casting can be made to very close dimensional tolerances.

- The casting produced have very good surface finish, so further machining is eliminated.

- Castings are free from most of the usual defects.

- Castings of intricate shapes can be easily cast.

Disadvantages of Investment Casting

- Size of the castings produced is limited. This method is not suitable for casting large size parts.

- Increased cost of production due to cost of expendable pattern.

- Time required for casting is more.

Applications of Investment Casting

- Parts of air craft engine.

- Nozzle, vanes and blades of turbine.

- Jewellery items.

- Parts of machine tool, accessories, instruments etc.