A heat pipe is a heat transfer device in which the transfer of heat between the hot and cold regions takes place in vaporised about condensed forms of working fluid. The condensed fluid in a heat pipe, flows from cold to hot region due to capillary action.

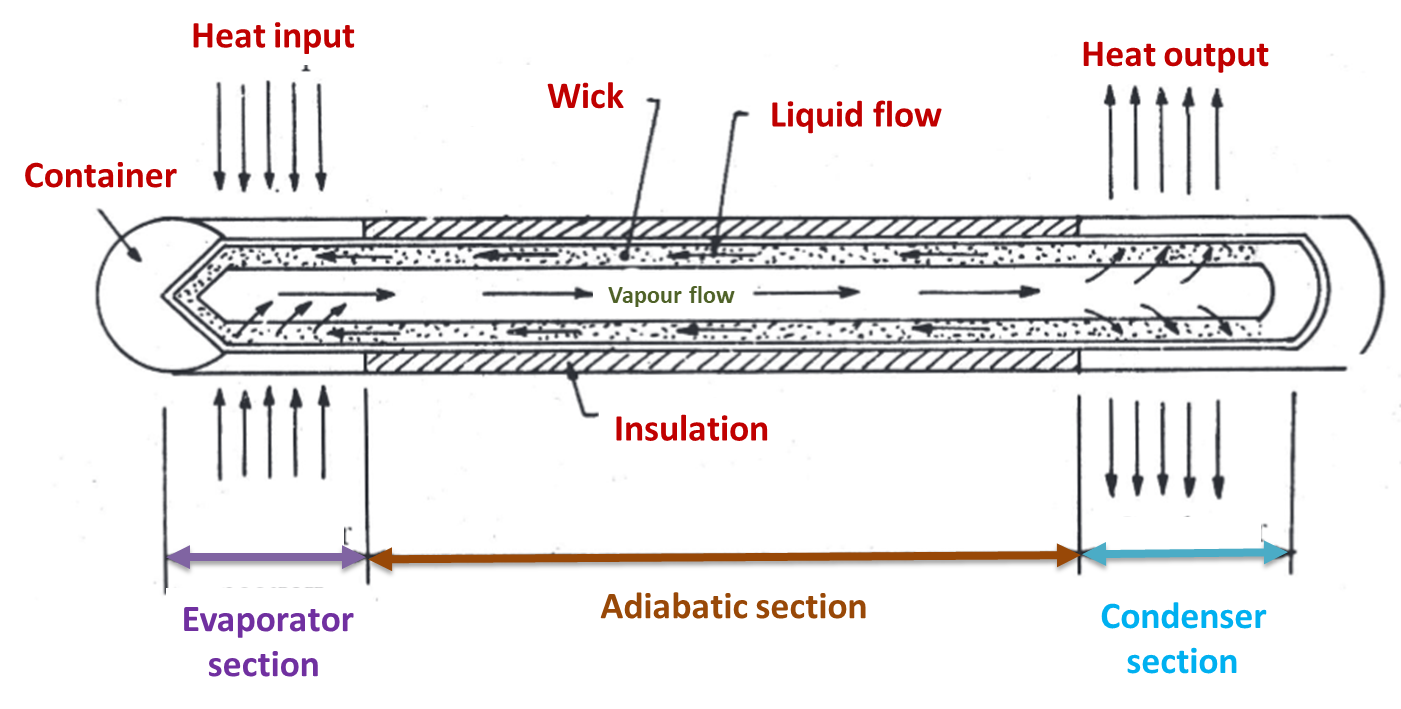

Figure 1: Heat Pipe.

Working of Heat Pipe

The heat pipe is a type of heat exchanger that uses the principles of phase transformation and thermal conductivity, to transfer heat in between two interfaces. These pipes are also called as superconductors due to their impeccable heat transfer capabilities. This device is a sealed container which is usually a pipe-like structure, consists of two ends and is filled with a work in a fluid. One end of the heat pipe is connected to the heat source and the other end is connected to the device to which heat is to transferred and a porous material called a wick is arranged on the inner walls of the pipe. When the evaporator section experiences high temperature, the working fluid gets evaporated and the vapour exerts pressure, this rise in pressure causes the vapour to flow to the condenser region. In this region, the heat is rejected to the sink or the device need to be heated and therefore, the fluid in heat pipe condenses. This condensate is driven back to the evaporator end by the capillary action in the wick. Hence in a heat pipe, the heat transfer occurs through the capillary movement of fluid.

A heat pipe works efficiently when the evaporator end is below the condenser end or when both the ends are in same horizontal line, because the return of working fluid from condenser end is due to both capillary action and gravity. If the condenser end is below the evaporator end, the fluid must flow against the gravity which decreases the rate of fluid flow thereby decreasing the heat transfer rate.

Types of heat Pipes

In general, the shape of heat pipes is not confined to the circular cross-section, there are heat pipes with other shapes also. The different kinds of heat pipes are as follows.

Capillary Heat Pipe with Multiple Tubes

In this kind of heat pipes, there are multiple tubes between evaporator and condenser regions for the flow of vapours. While the flow of condensate solely depends on capillarity. In horizontal heat pipes, internal heat exchange of 10000 W/m2K is achieved whereas the external heat transfer coefficients being only 50W/m2K between fluid inside the heat pipe and external forced air stream. Due to this, surface areas of condenser and evaporator regions must be 30 and 20 times greater than the heat pipe’s cross-sectional area respectively. Heat pipes with circumferentially grooved wicks, are able to transfer heat tip to 80000 W/m2K with water as a working fluid.

Flexibility Heat Pipes

When vibrations are involved, it is difficult to install a heat pipe. To overcome this problem, heat pipes are made with flexible bellows in which the design of the wick is capable to transfer heat under vibrating conditions.

Rotating Heat Pipe

The heat pipes of this kind are designed in a shape of truncated cone. The wider end of pipe is a evaporator region and the other end is a condenser region. As the vapour condenses and reaches the condenser region. As the heat pipe is allowed to rotate on its own axis. Due to the centrifugal force, fluid flows towards the evaporator region. Thus, the rate of fluid flow is proportional to the angular momentum.

Heat Plates

These are not considered as a heat pipes, but their function is similar to heat pipes. The heat plates are arranged with a mesh of wicks and vapour passages alternatively. One end of heat plate act as a condenser region and the other as a evaporator region similar to conventional pipes. A flat heat plate works only when it is oriented horizontally.

Heat Pipes with Gravity Induced Fluid Flow

In this kind of heat pipes, the wick is designed relatively smaller and is only for providing thermal insulation between vapour and liquid. And. the flow of fluid from the condenser region to evaporator region is entirely due to gravity.

Heat Pipe with the Osmotic Flow

In this kind of heat pipe, the sugar solution is used as a working fluid. When the evaporator region is exposed to heat, the water in the sugar solution gets vapourised and travels towards the condenser region where it transfers its latent heat by condensation. A semi-permeable membrane (cellulose) is arranged in between vapour region and fluid flow as a result osmotic pressure is developed on the condensate, due to which water flows into the sugar solution and the cycle is repeated. This kind of heat pipes can be arranged with condenser end lower than the evaporator end, because the gravitational pull is smaller than the osmotic pressure where this arrangement is not possible with conventional capillary heat pipes. The major drawback is that the flow rate of fluid through the membrane is very slow and thus the capacity of this heat pipe is smaller.

Electro-osmotic Heat Pipes

An electric field is applied along the heat pipes with the osmotic flow, due to the electro-osmotic effect the speed of the fluid increases along the wick. This effect only occurs when fluids with high dielectric nature are used as a working fluid. In few designs, where fluids flowing up to 500 mm against gravity this phenomenon is observed and it is almost impossible to observe in conventional heat pipes which solely depend on capillarity.

Inverse thermosiphon heat pipes

The evaporator region of this kind of heat pipes is above the condenser region. A return tube with an auxiliary heater on one end is arranged between condenser and evaporator regions. The other end of the return tube is dipped in the condenser region. The condensed vapour enters into the return tube, where the auxiliary heater heats the liquid and vapour bubbles are produced. Due to the density difference between pure fluid surrounding the return tube and vapour or liquid column in return tube, the fluid flows from condenser region to evaporator region.

Applications of Heat Pipe

The following are the applications of heat pipe.

- These pipes are used in industrial plants for heat recovery purpose.

- In aerospace for temperature stabilisation and cooling of space craft.

- These pipes are used for cooling of electronic components.

- These pipes carry heat from ovens and furnaces.

- Heat exchangers.

- In solar thermal applications such as.

- Solar distillation.

- Solar cooking.

What are the characteristics of fluids used in heat pipes?

The fluids used in the heat pipes must possess the following characteristics.

- The fluids must be chemically stable and does not react with the heat pipe material.

- Purification and degasification of fluids must be easy.

- The cost of fluid should be economical.