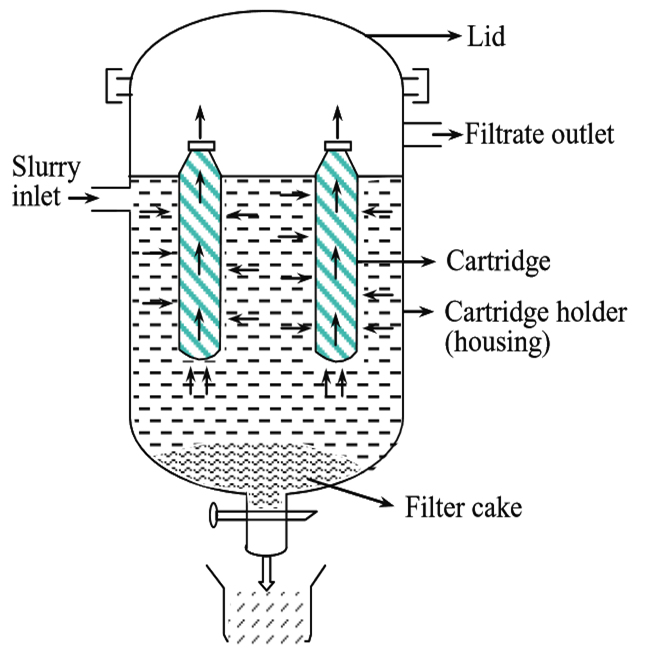

Figure 1: Assembly of Cartridge Filter.

Working Principle of Cartridge Filter

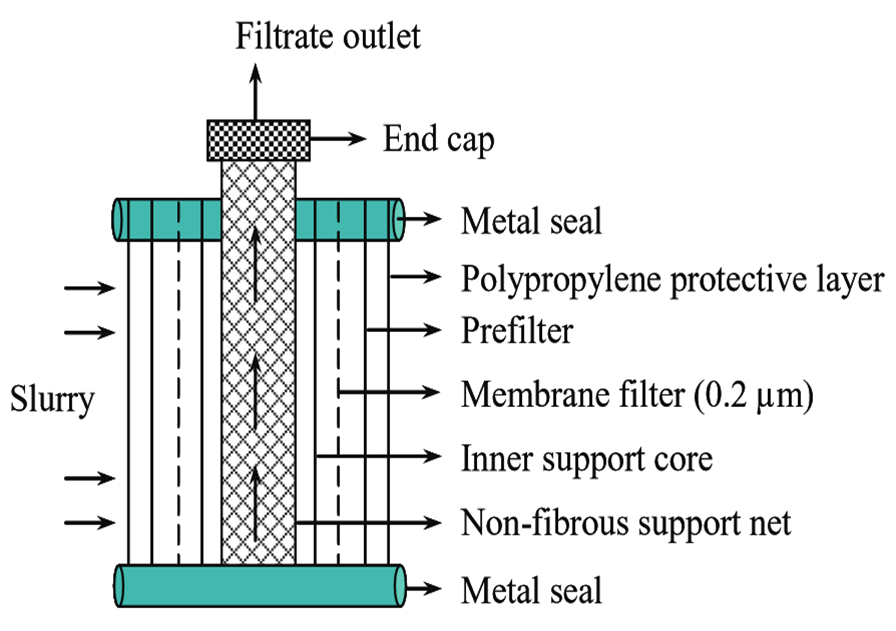

The prefilter and membrane filters are combined into a thin porous membrane. The principle involved is surface filtration (see Figure 1).

Construction of Cartridge Filter

Figure 2: Cartridge Filter Unit.

The cartridge filter is cylindrical in shape, wherein the filter media is replaceable (see Figure 2). The filter media is double layered with a prefilter and a membrane filter. The membrane filter is the actual filter for filtration. Both the filter media are covered by a polypropylene protective layer. Cartridge filters are placed in housing and covered with a lid. The housing has a slurry inlet and filtrate outlet.

Working of Cartridge Filter

As the slurry is introduced into the housing, it is filtered through the cartridge filter by surface filtration and by the mechanism of straining. The filtrate drains to the centre and is collected through the filtrate outlet.

Advantages of Cartridge Filter

- Along with filtration, simultaneous sterilization with autoclaving can be carried out with stainless steel construction.

- Nowadays, cartridges are available with self-cleaning devices.

- The construction allows dismantling.

- Applicable for continuous filtration thereby reducing the chances of contamination.

Disadvantages of Cartridge Filter

- High labour cost is required for dismantling the machine and also for its cleaning.

- The components of the machine cannot be bought from different manufacturers because they differ from manufacturer to manufacturer.

Applications of Cartridge Filter

- Filtration of parenteral and ophthalmic solutions.

- Filtration of 1000-15,000 liters of sterile solution per hour is possible.