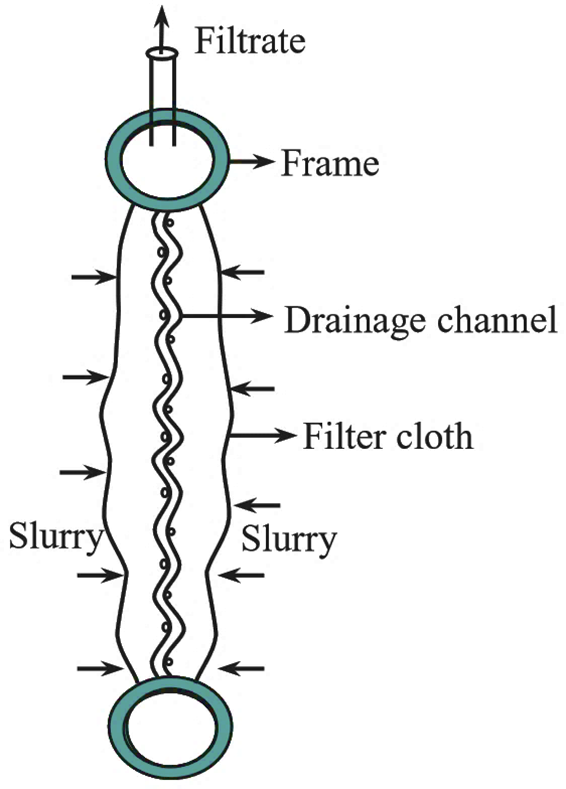

Figure 1: Leaf Filter.

Working Principle of Leaf Filter

The mechanism involved in the working of leaf filter is surface filtration (screen filtration), in which the retention of solid particles occurs due to the larger size of solid particles than the pore size of the filtering medium. To enhance the filtration rate, pressure or vacuum can be applied.

Construction of Leaf Filter

Leaf-filter consists of the following parts (see Figure 1).

- The frame may be round, rectangular or square in shape.

- The drainage channel is connected to the frame.

- Filter cloth acts as a filter medium by retaining the solid particles of slurry. The entire unit (i.e. frame, drainage channel) is covered with the filter medium.

- The outlet which discharges the filtrate. This is connected to the inside of the frame.

Working of Leaf Filter

Leaf filter is dipped in the feed and a receiver and vacuum system is connected to the filtrate outlet. As the leaf-filter is immersed in the feed, the filtrate passes through the filter cloth and enters into the drainage canal. It then gets collected in the receiver. The solid particles are deposited on the filter medium. The filter cake can be washed simply by immersing the filter in a vessel containing water. Then, the filter cake is removed by reverse airflow.

Disadvantages of Leaf Filter

- Leaf filters are suitable only for dilute solutions i.e. when the concentration of solids present in slurry is less than 5%.

- Leaf filter is used only for batch processes hence it is associated with a good deal of downtime, which is not productive.

- The design of leaf filter is complicated

- Efficient washing of cake in leaf filter consumes more amount of water.

- It is expensive.

Applications of Leaf Filter

- Leaf filters are widely used in metallurgical industry.

- They are employed for the recovery of valuable precipitates.

- Leaf filters are widely used when large volumes of solid is to be filtered per unit volume recovered.

- Leaf filters are employed satisfactorily for dilute suspensions.

Modification of Leaf Filter

Sweetland Filter

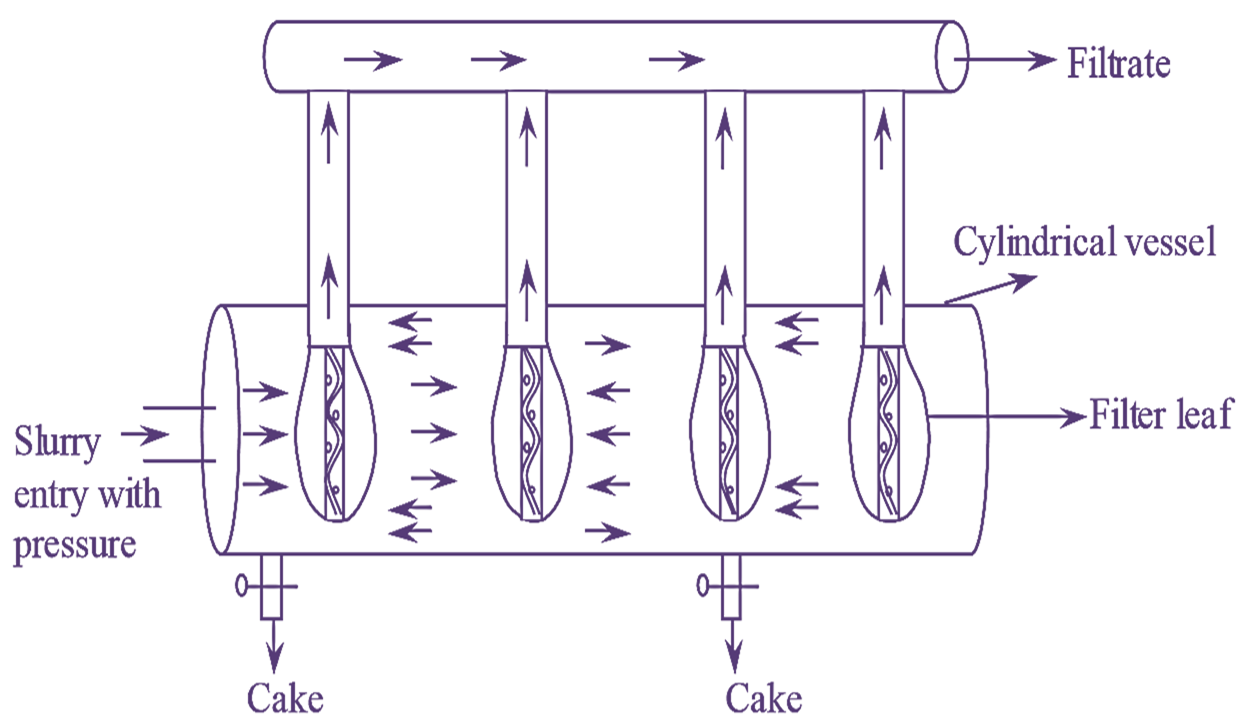

The Sweetland filter is cylindrical in shape (see Figure 2). It consists of assemblies of leaf filters to provide large filtering area. These leaf filters are connected to a common outlet through which the filtrate leaves. The leaf filters are held at the top with a common outlet with their lower part swinging free.

Figure 2: Sweetland Filter

Advantages of Sweetland Filter

- Ease of hand1iig

- Less floor space

- Minimum labour.

- Efficient washing

- Versatile as the filtration area can be varied by number of units, operated under pressure or vacuum.

- Pressure up to 800 kilopascals can be applied.