Radial drilling machines are most suitable for drilling on large and heavy workpieces and can drill holes up to 50 mm in diameter. The radial and vertical motion of the arm. horizontal motion of drill head over radial arm makes the machine more versatile.

Parts of Radial Drilling Machine

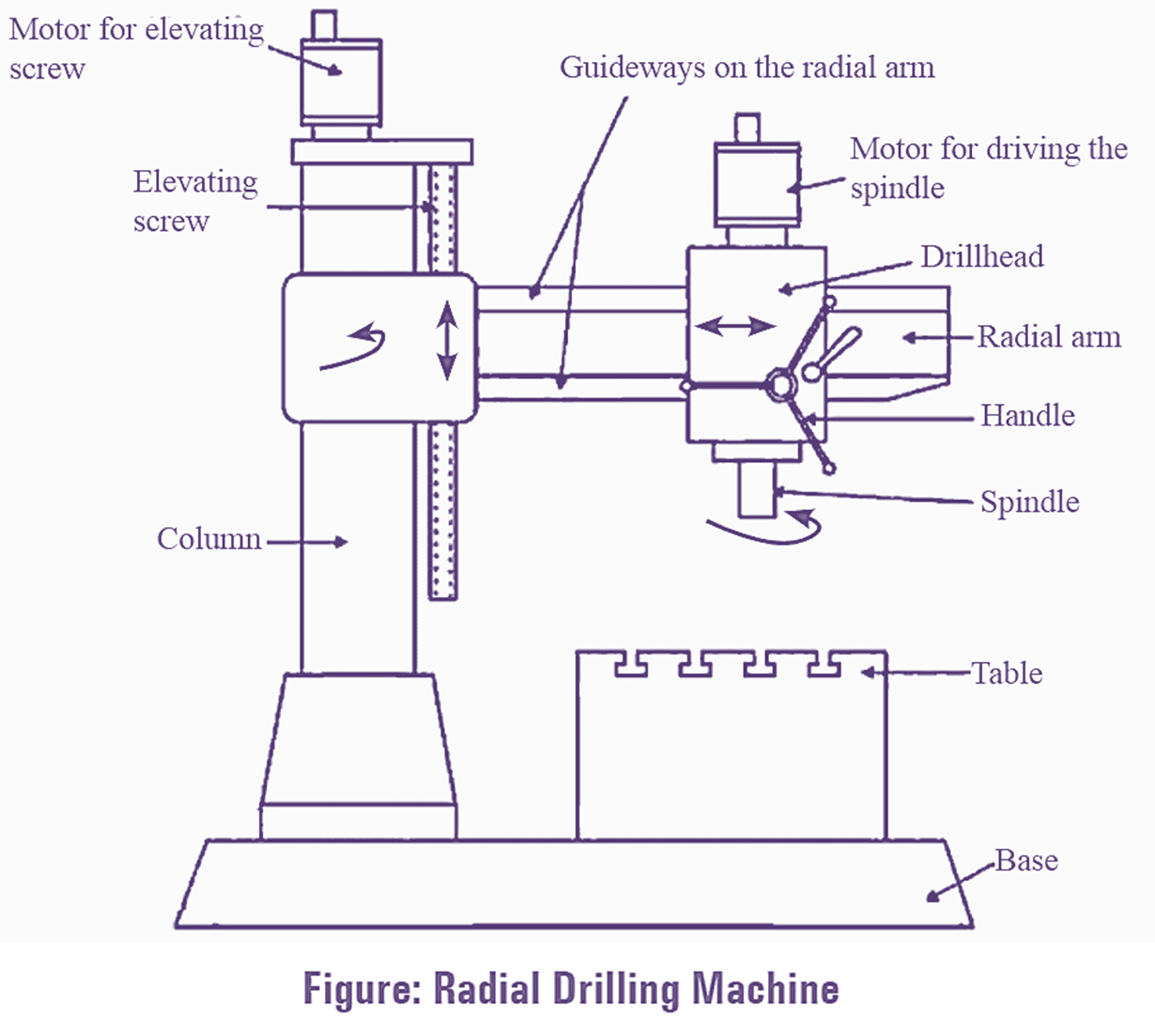

The main parts of a radial dulling machine are as follows,

Base:

It is a heavy rectangular structure made of graded steel whose upper surface is accurately finished and provided with T slots to clamp work holding devices or to mount heavy works directly. On one end of the base has a vertical column is supported and on another end is mounted with a work table. The base is designed in such a way that it can tolerate heavy vibrations produced while drilling.

Column:

It is a vertical cylindrical structure mounted on the base and is equipped with the motor on top of the column and an elevating screw to provide vertical motion to radial arm in either direction.

Radial Arm:

It is a horizontal extension mounted on the vertical column and can slide vertically on the guideways provided on the column and also can swing around the column tip to 180° or more. Guideways are provided oui front vertical face upon which drill head is slid.

Drill Head:

It is a heavy rigid casting mounted on the guideways of the radial arm and can slide along the guideways to alter the position of the spindle according to the workpiece. It acts as a housing for all the mechanisms of speed and feed.

Spindle Speed and Drive Mechanism:

In most of the cases, a constant speed motor is directly mounted on top of the drill head and spindle obtains multiple speeds and feeds through motor via gear trains. In some cases, the motor is mounted on another side of the radial arm to partially balance the weight of the drill head. And is connected to spindle through bevel gears.

Advantages of Radial Drilling Machine

- The arrangement is simple and any improvements or modifications can be done easily.

- More than two holes can be drilled at a time with the help of proper jigs.

- The various operations such as tapping. reaming. boring, counter-boring, trepanning, spot facing, counter-sinking, etc.. can also be done on this machine.

- It does not requires highly skilled operator.

- The cost of operation is less and is a quick process.

- The work table and base of machine has capacity to accommodate different sizes and various types of jobs.