In this topic, you study AC Servo motor – Working Principle, Circuit Diagram, Construction, Characteristics & Applications.

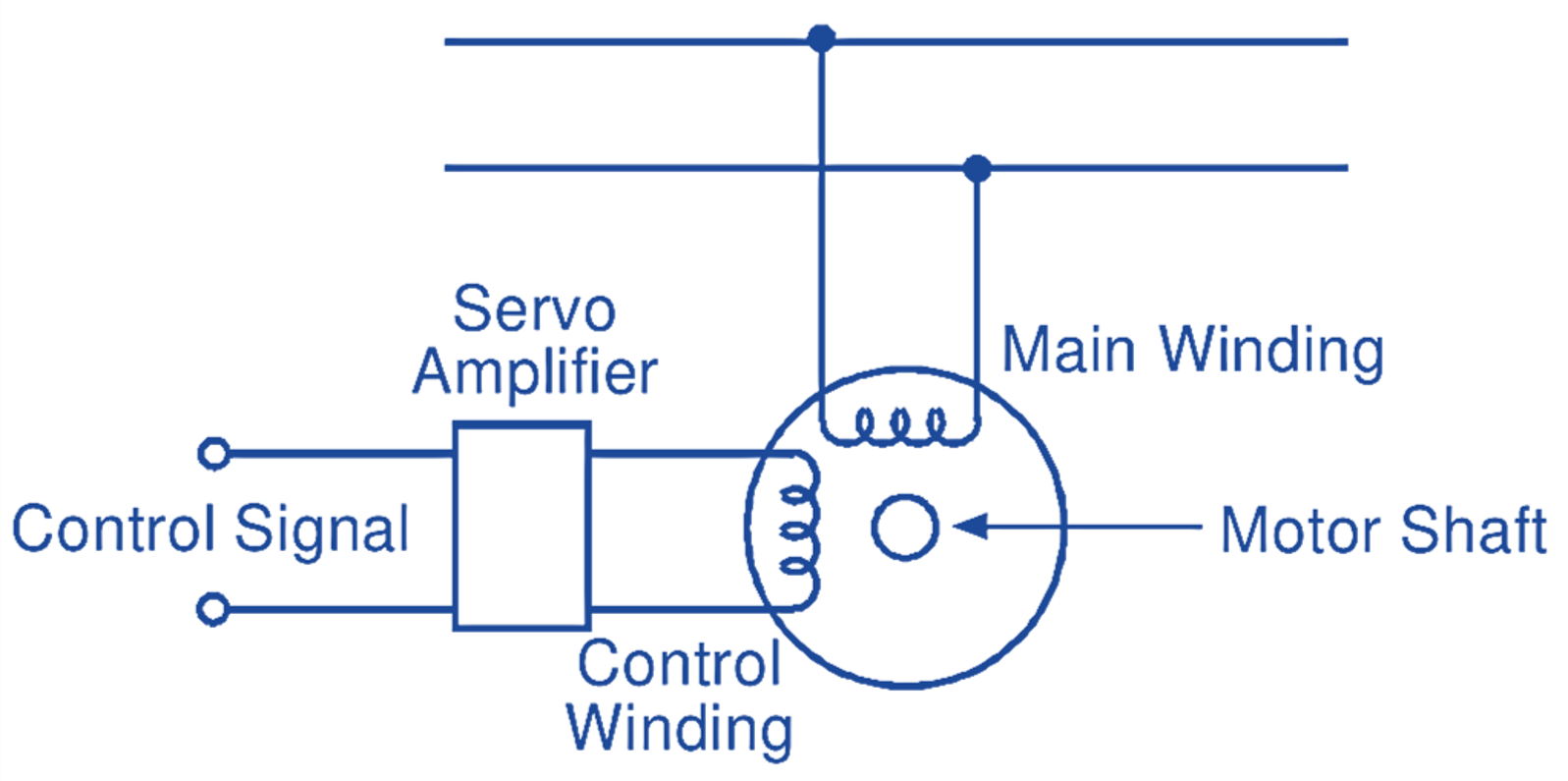

Most of the servo motors used in servomechanisms are ac and AC servo motors are of the two-phase induction motor type. Fig. 1 represents the circuit diagram of AC servo motor.

Fig. 1: Circuit diagram of AC servo motor.

Construction of AC Servo motor

Similar to a normal induction motor, this motor comprises of a stator and a rotor.

Stator of AC Servo motor

The stator of this motor which has a laminated structure, is wound with its two windings placed 90 electrical degrees apart in space. One of the windings called the main winding (also called as reference or fixed phase) is excited from the constant-voltage supply source. The other winding called the control winding (or control phase) is energised by the variable control voltage which is 90 electrical degrees out of phase with respect to the voltage across the main winding. This control voltage is supplied from a servo amplifier.

Rotor of AC Servo motor

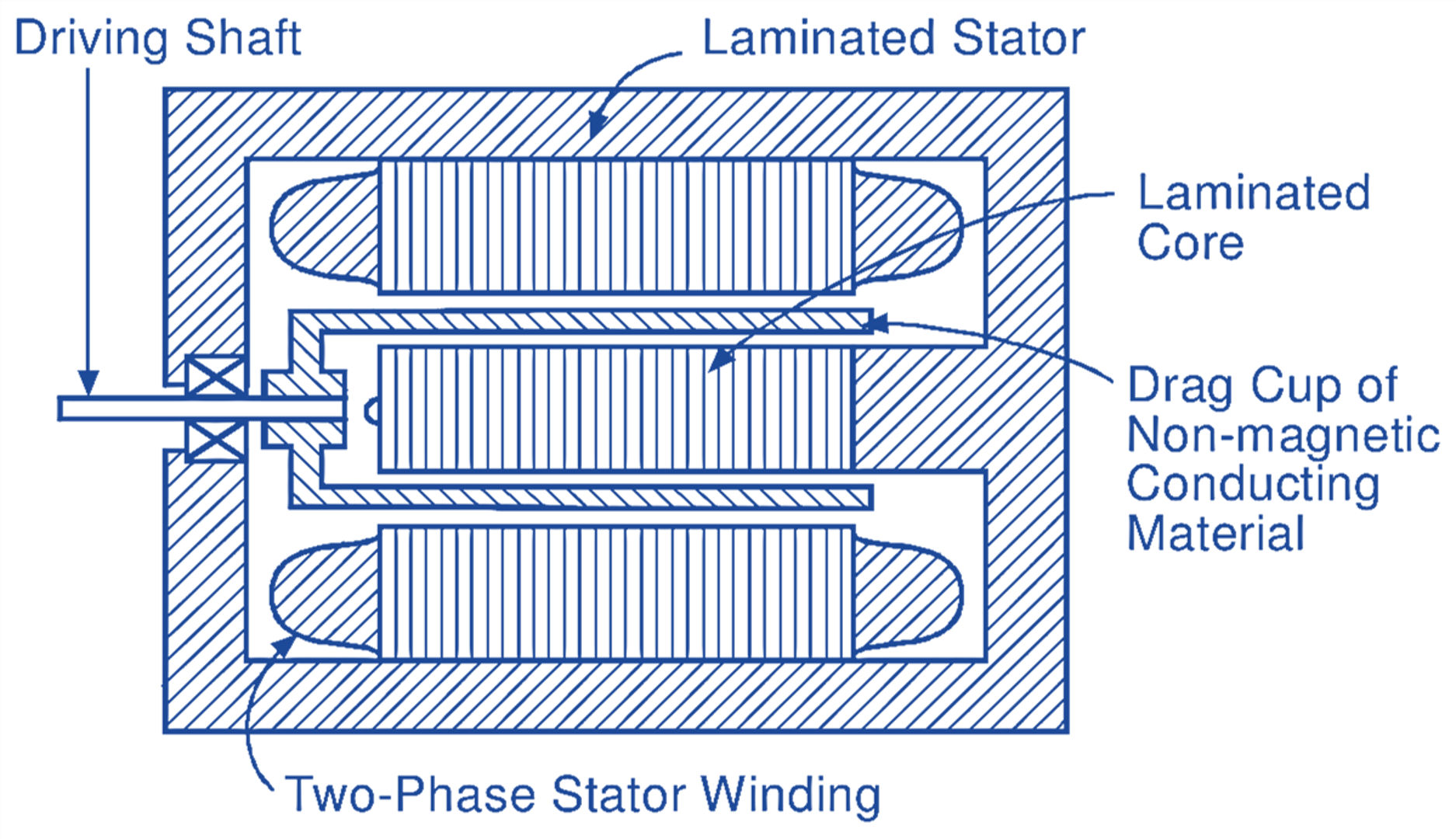

The rotor is usually of the squirrel cage type with small diameter and large length to keep the mechanical inertia as low as possible. It has high resistance in order to obtain a torque-speed characteristic as linear as possible. The inertia of the rotor is further reduced using drag-cup rotor (Fig. 2) for very low power applications. This type of rotor is a special form of squirrel-cage rotor in which conductors are in the form of a drag-cup made of a non-magnetic conducting material such as copper, aluminium, or an alloy. The slotted rotor laminations are replaced by a set of stationary ring shaped laminations that provide a low-reluctance path for the magnetic flux.

Fig. 2: Cross-section of a two-phase servo motor with drag-cup type rotor.

To minimize rotor kinetic energy, servo motors are wound with as many poles as possible so that they operate at low speeds. This also provides corresponding increase in torque. AC servo motors have small air gaps to reduce magnetizing current and consequent losses.

Working Principle of AC Servo motor

The principle of operation of ac servo motor is same as that of an ordinary two-phase induction motor. When two voltages with time phase difference of 90 electrical degrees are applied to the two stator phases 90 electrical degrees apart in space, a rotating magnetic field is produced. As the field sweeps over the rotor, e.m.f.s and hence the currents are induced in the rotor conductors forming a closed path. The rotating magnetic field interacts with these currents producing a torque on the rotor in the direction of field rotation.

Characteristics of AC Servo motor

Torque-Speed Characteristics of AC Servo motor

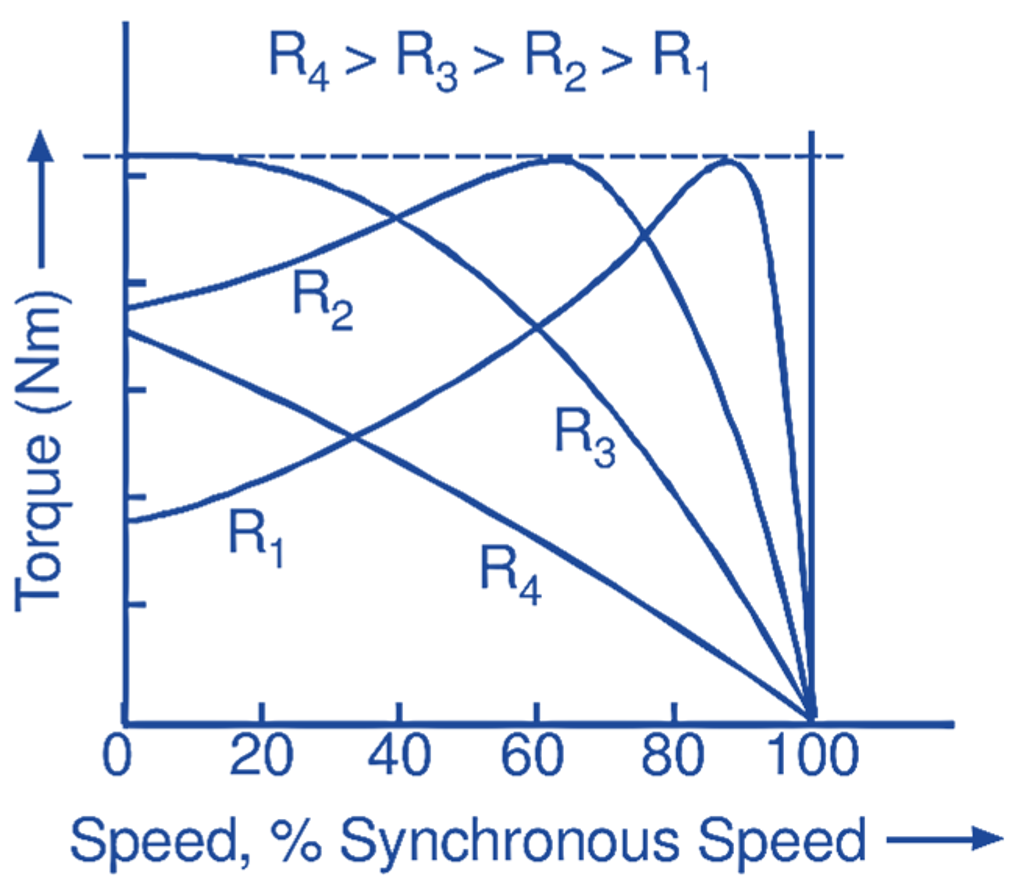

We know that the general shape of the torque-speed characteristic of a two-phase induction motor depends largely on the value of rotor resistance (Fig. 3). Increasing the rotor resistance linearizes the speed-torque characteristics. Because of this, the rotor of the servo motor is built with high resistance so that its torque-speed characteristic is nearly linear.

Fig. 3: Variation of torque-speed characteristics of an induction motor with rotor resistance.

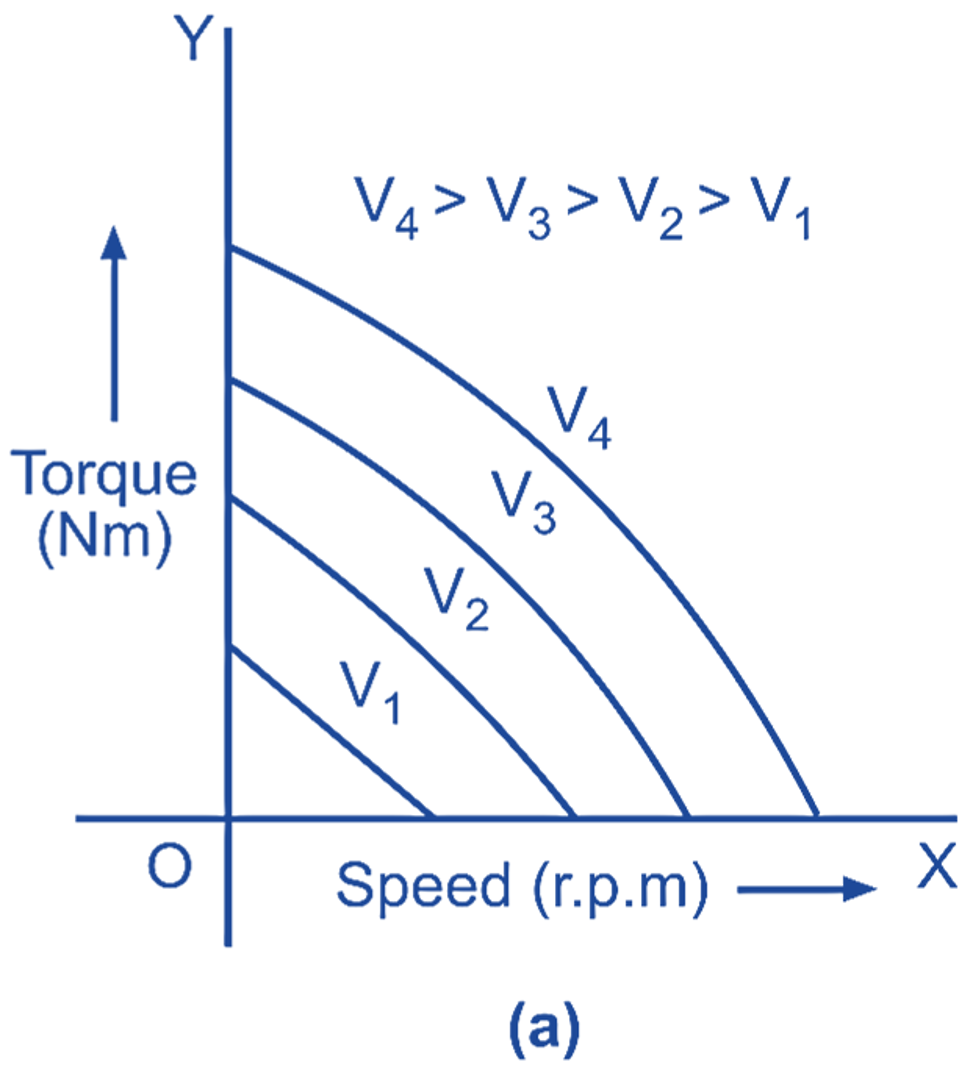

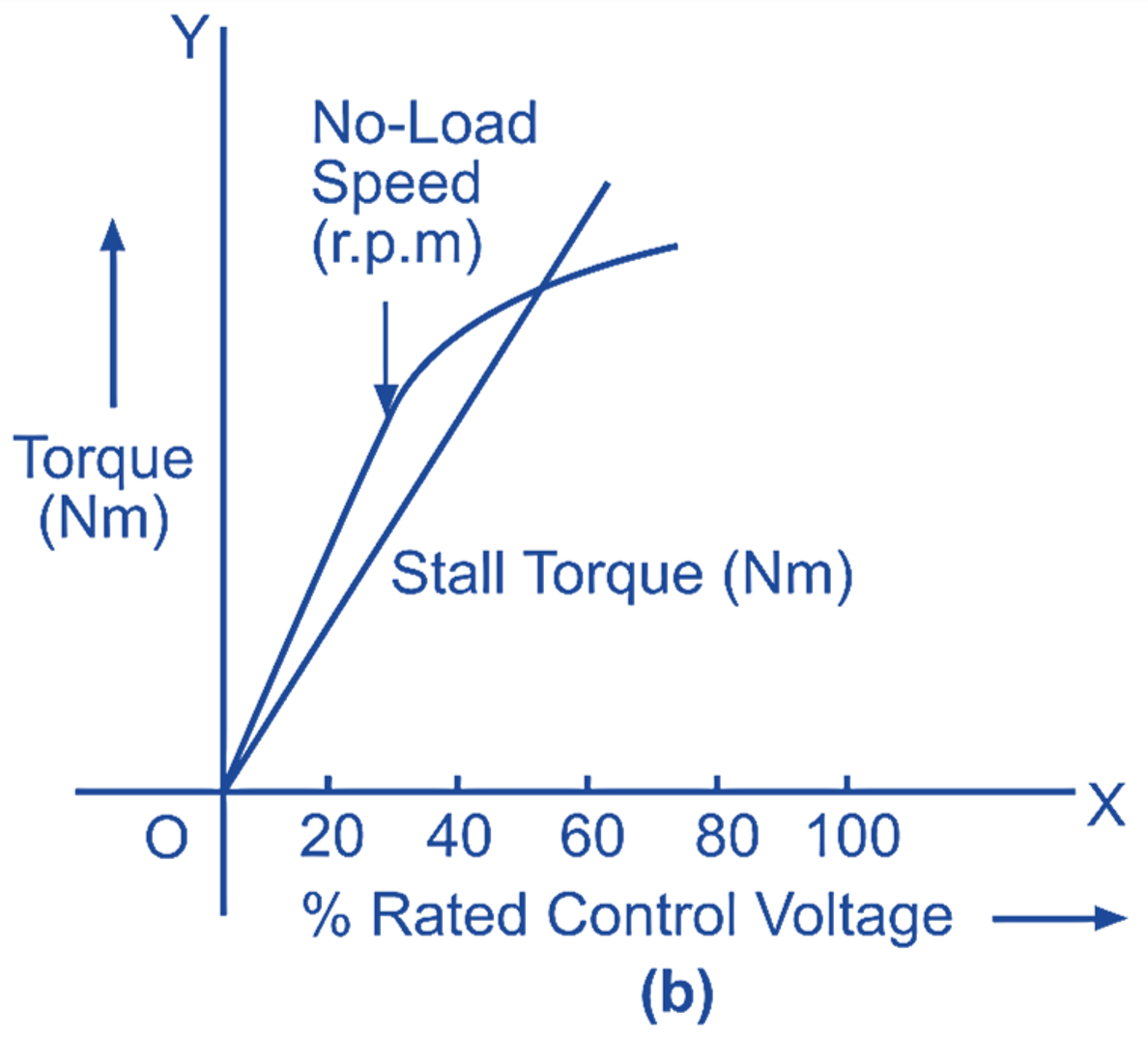

Fig. 4 (a) shows the torque-speed characteristics of a servo motor for various control voltages (V1, V2, V3, V4, etc.). It will be observed that the torque (particularly stall or starting torque) varies almost linearly with speed as well as with control voltage. The torque for any particular value of control voltage is high in the zero speed range and decreases as the motor speeds up. The drop in torque serves as a stabilising feature for the control system. Fig. 4 (b) shows the no-load speed and stall torque versus control voltage curves (with fixed-phase voltage constant).

Fig. 4 (a) Typical torque-speed characteristics of a servo motor (ac) for various control voltages, (b) No-load speed and stall torque versus control-voltage curves.

Other Performance Characteristics of AC Servo motor

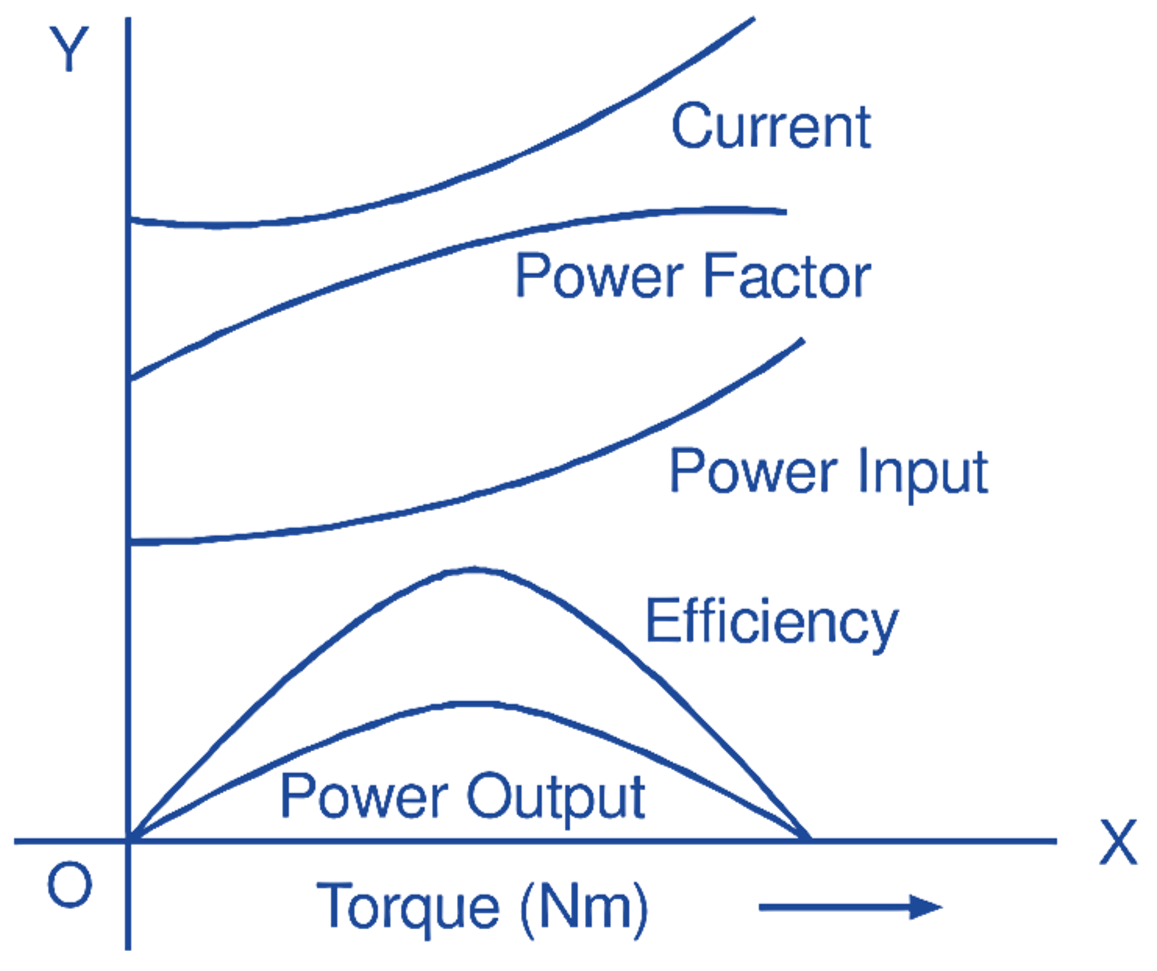

Fig. 5 illustrates some other performance characteristics of a typical ac servo motor.

Fig. 5: Performance characteristics of a typical ac servo motor.

Applications of AC Servo motor

Because of their ruggedness, light-in-weight construction, high torque-to-weight ratio, reliability, freedom from radio noise, and the simplicity of their driving circuits, ac servo motors are widely used particularly in instrument servos, computers, tracking and guidance systems, self-balancing recorders, remote-positioning devices, process controllers, robotics, machine tools, special purpose machines, and in other numerous applications where precision angular motion is required.