In this topic, you study DC Servo motor – Theory, Circuit Diagram, Types, Characteristics & Applications.

Except some minor differences in constructional features, a dc servo motor is essentially an ordinary dc motor (usually shunt). To meet the requirement of low inertia, dc servo motors are designed with large length-to-diameter ratio for their armatures. Further, to attain linear torque-speed characteristics, they are generally separately excited.

Types of DC Servo motor

DC servo motors can be controlled by using either the current of the field winding or the armature current. Accordingly, they are classified as:

- Field controlled dc servo motors,

- Armature controlled dc servo motors.

Field Controlled DC Servo motor

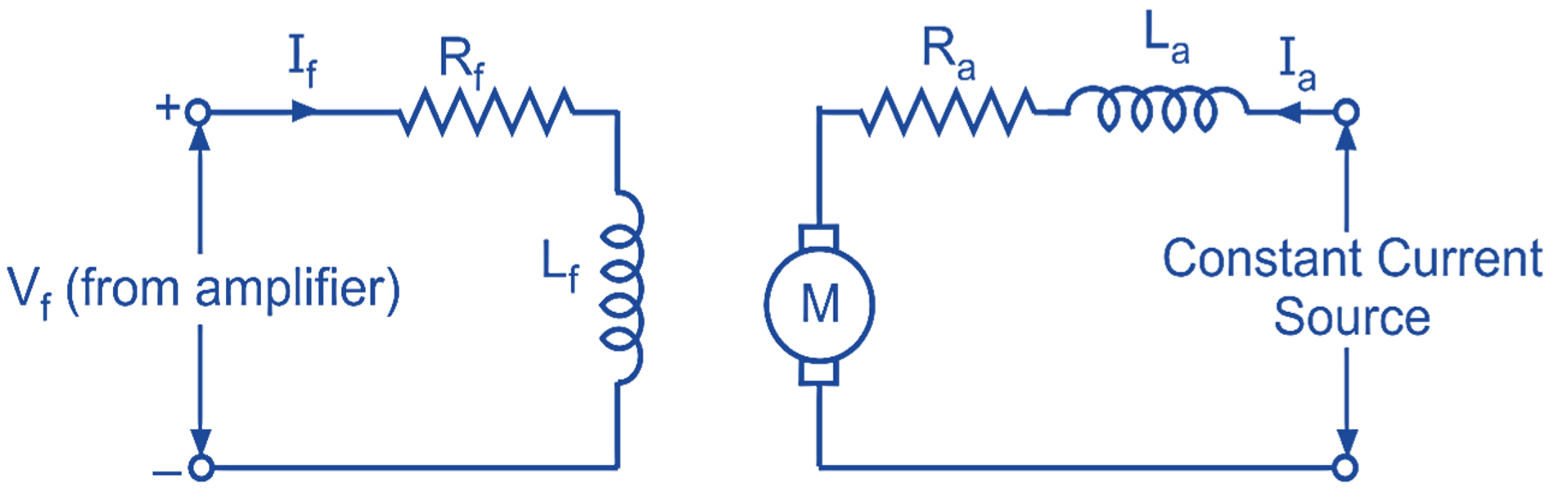

In this type of motor, the output (i.e. control signal) from the servo-amplifier is applied to the field winding keeping the armature current constant (Fig. 1).

Fig. 1: Field controlled dc servo motor

Even though the power required for field control is only a fraction of the power required for armature control, it is less common. This is because the time constant of the field circuit (Lf / Rf) is large compared with the armature circuit time constant (La / Ra). Consequently, field control does not give as rapid response as armature control. Also, the torque-speed characteristics under field control is not as linear as under armature control. Field control is normally used for small size motors as only a low power servo-amplifier is required, while the armature current which is not large can be supplied from an inexpensive constant-current source.

Armature Controlled DC Servo motor

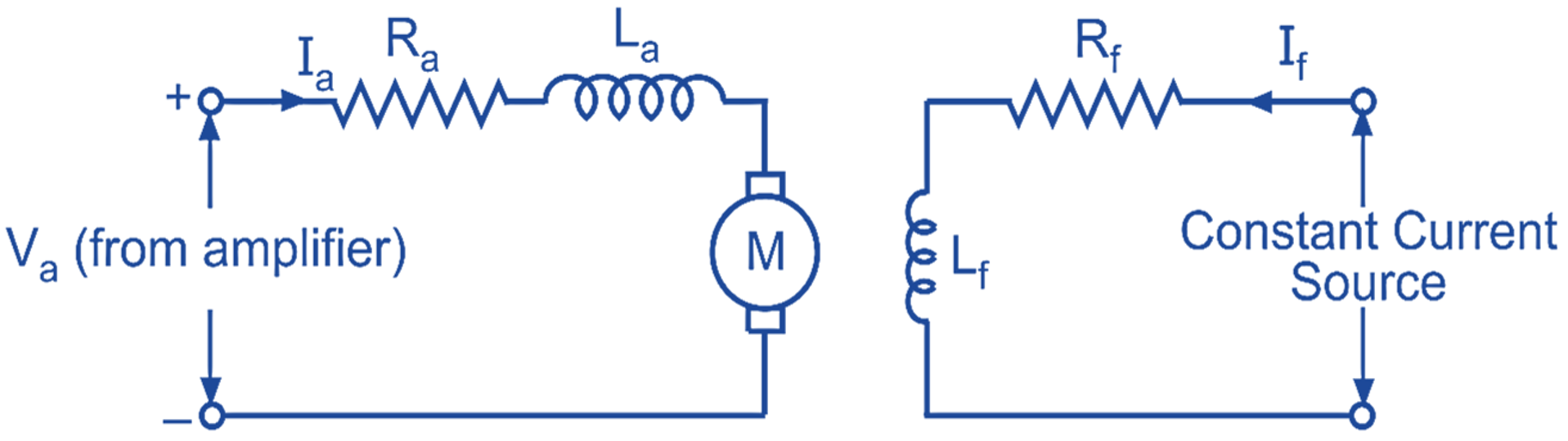

Fig. 2 illustrates this type of dc servo motor. In this case, the output (i.e. control signal) of the servo-amplifier is applied to the armature winding and the field current is kept constant. As already mentioned earlier in comparison with field control, armature control gives nearly, ideal linear performance with rapid response. For large size motors, use of armature control becomes on the whole more economical.

Fig. 2 : Armature controlled dc servo motor

The constant field in the above case can be supplied using a permanent magnet. Such a motor is then called the permanent-magnet motor. Since no field coils are required, these motors are rugged, relatively less expensive, and have better efficiency and overall performance (with straighter speed-torque characteristics).

Characteristics of DC Servo motors

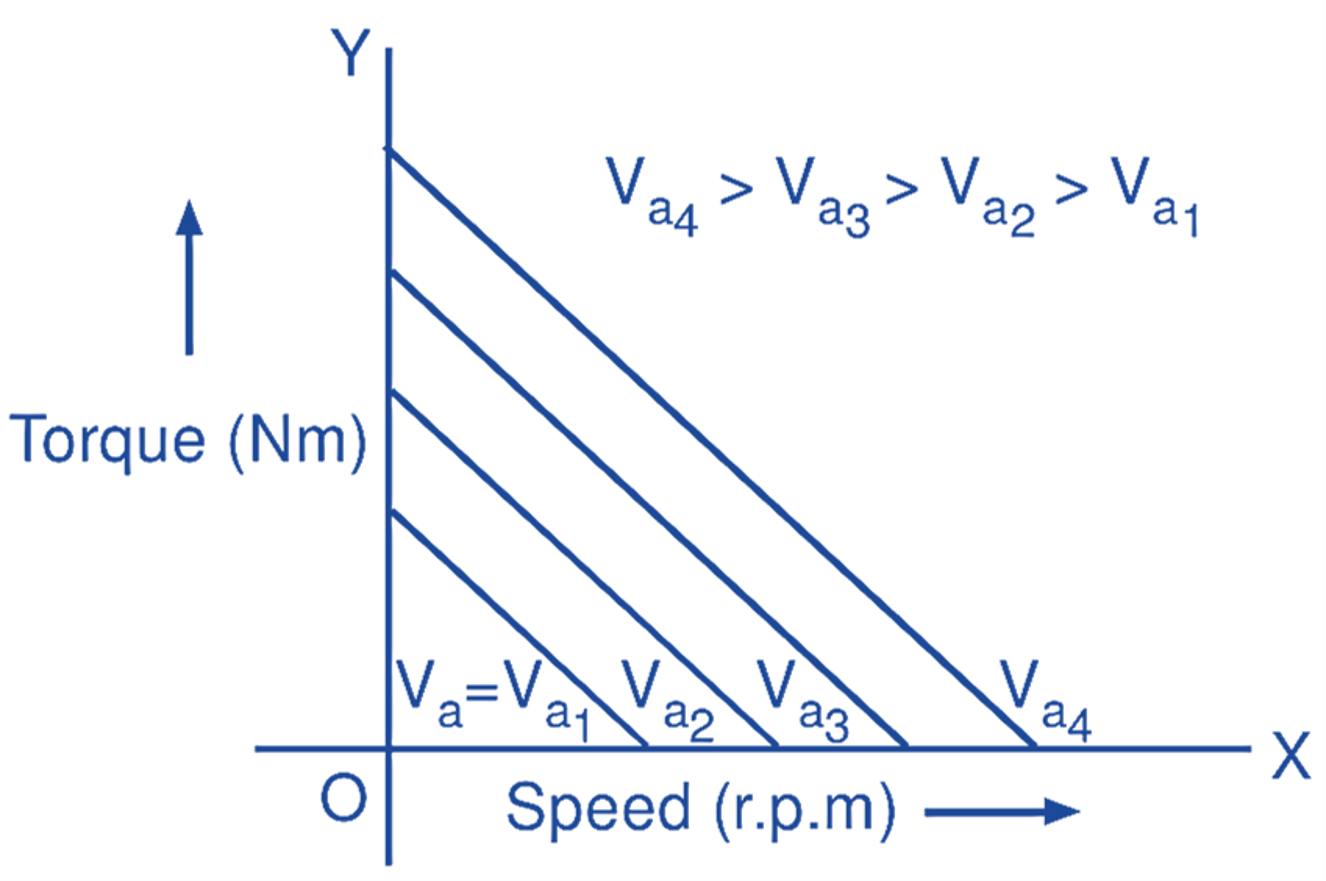

Torque-Speed Characteristics of DC Servo motor

Torque-speed characteristics of dc servo motors are quite similar to those for ac servo motors (Fig. 3). Comments made earlier regarding starting torque and stability consideration in respect of torque-speed characteristics of ac servo motors are therefore, equally applicable to torque-speed characteristics of dc servo motors.

Fig. 3: Family of torque-speed curves for an armature controlled dc servo motor with varying control voltage

Other Performance Characteristics of DC Servo motor

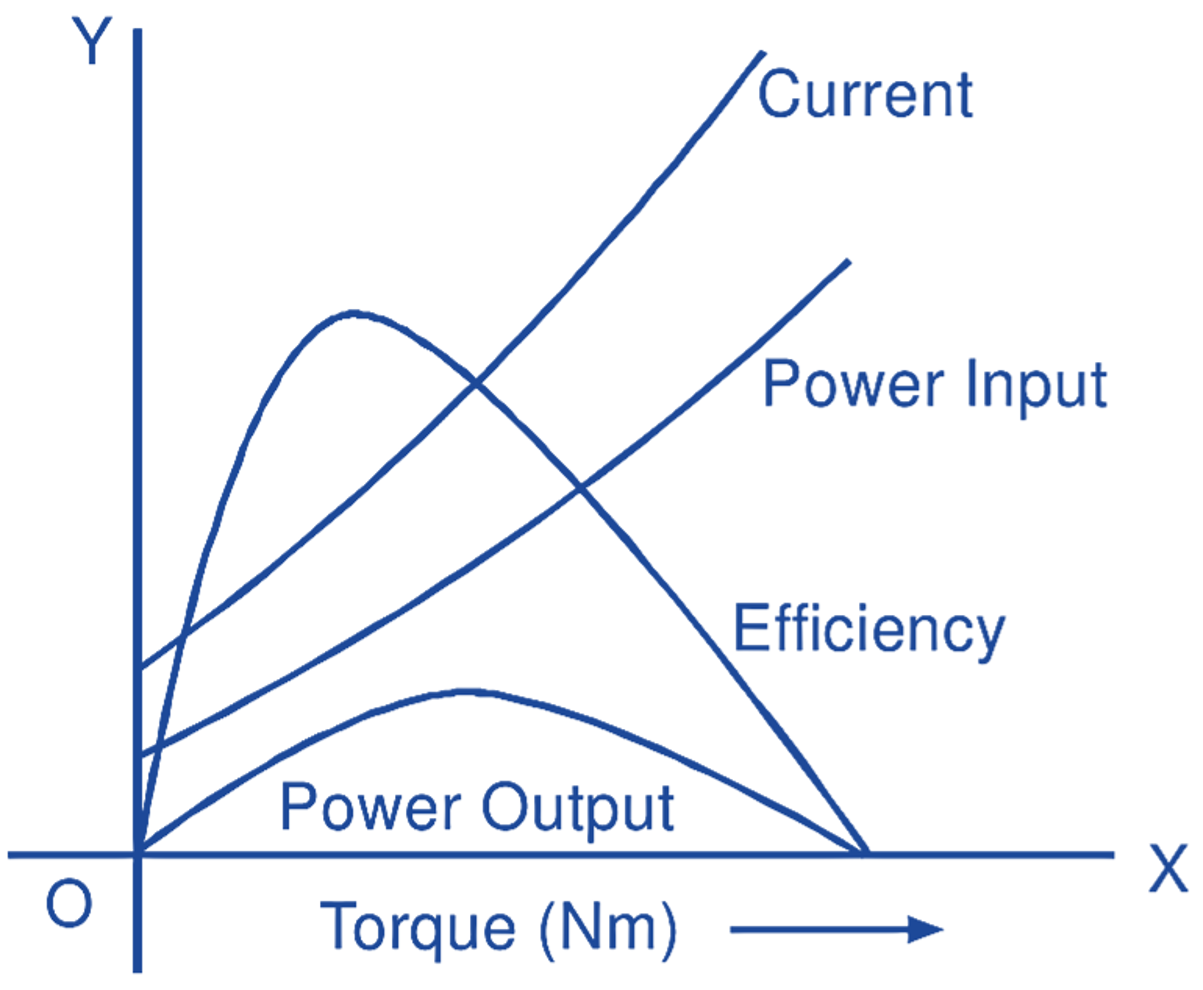

Fig. 4 shows some other performance characteristics of a typical dc servo motor.

Fig. 4: Performance characteristics of a typical dc servo motor.

Applications of DC Servo motor

The inertia of dc servo motors tends to be larger than that of squirrel-cage ac motors. This and added frictional drag of brushes are the main factors which discourage their use in instrument servos. In small sizes, dc servo motors are primarily used in air-craft control systems where weight and space limitations require motors to deliver maximum power per unit volume. They are often used for intermittent duty or where unusually high starting torques are required e.g. for fan and blower drives. They may also be used for electromechanical actuators, process controllers, programming devices, robotics, machine tools, special purpose machines, and for a host of other applications of a similar nature.