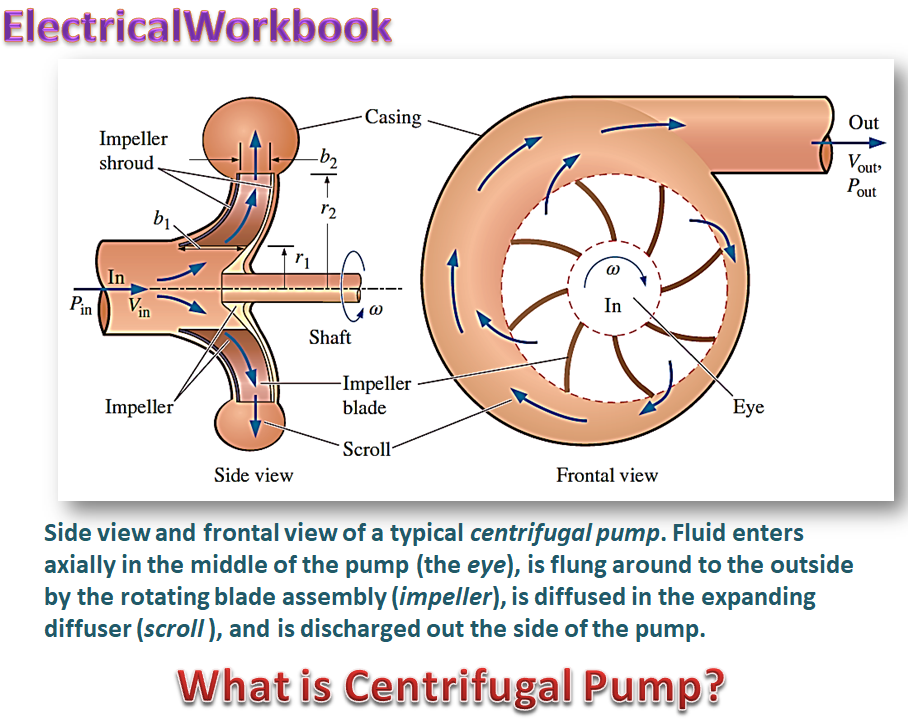

In a centrifugal pump, the fluid is rotated with high speed, to rise beyond the restricted walls of the casing by means of centrifugal action of impeller. Then the liquid flow out.

Centrifugal Action in Centrifugal Pump

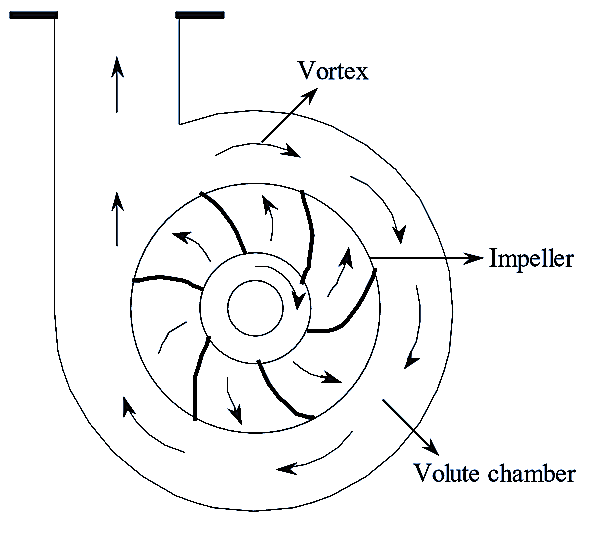

Figure 1: Centrifugal Action.

The pressure difference is caused due to spiral forced vertex flow with the help of centrifugal action. ‘Whirling action is added to fluid by means of blades (generally backward curved blades) of impeller of the pump. The liquid enters at centre of impeller (i.e., eye) and discharges into casing surrounding the impeller. The potential energy head developed by centrifugal action is entirely due to velocity of rotating impeller and not due to any impact or displacement. Hence, the pump is named after this action on liquids.

Parts of Centrifugal Pump

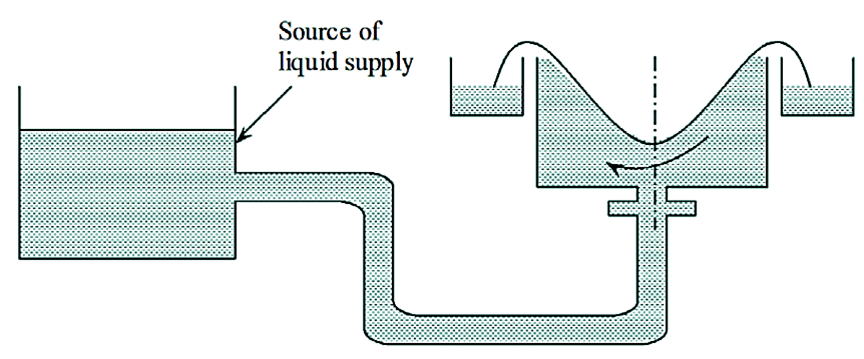

Figure 2: Centrifugal Pump

The main components of a centrifugal pump are as follows,

- Impeller

- Casing

- Suction pipes

- Delivery pipes

- Foot valve and strainer

- Delivery valve

- Pressure gauges

- Foundation base

- Foundation locking bolts

- Air valve, funnel etc.

Working of Centrifugal Pump

The first step in the operation of centrifugal pump is “priming”, it means removing all the air or gas or vapour from pump portion by filling water in suction pipe, casing and portion of delivery pipe up to delivery valve. Afier priming, close the delivery valve and start electric motor to rotate the impeller. Rotation of impeller in casing receives mechanical torque and produces forced vortex, which imparts a centrifugal head to water and causes increase in pressure. When delivery valve opens, the water is made to flow rapidly in outward direction. At the eye of the impeller, vacuum is produced due to centrifugal action, this helps to suck the water from sump (source of water) through suction pipe. The higher pressure water leaves the impeller and flows through delivery pipe to required height.

Classification of Centrifugal Pumps

The types of centrifugal pumps as,

According to the type of casing,

- Volute pump

- Diffuser or turbine pump.

According to the number of impellers per shaft,

- Single stage centrifugal pump

- Multi stage centrifugal pump.

According to the direction of fluid flow;

- Radial flow pump

- Axial flow pump

- Mixed flow pump.

According to the number of entrances to the impeller,

- Single suction pump

- Double suction pump

According to the disposition of shafts,

- Pumps with horizontal shafts

- Pumps with vertical shafts.

According to the head developed,

- Low head

- Medium head

- High head.

Advantages of Centrifugal Pumps Over Reciprocating Pumps

- Initial cost for installation of centrifugal pump is low.

- Installation and maintenance of centrifugal pump is easier and economical as it has small number of components.

- It is very compact and requires less space.

- It is a high speed pump and can be directly coupled to electric motor or oil engine.

- Discharging capacity of centrifUgal pump is higher than reciprocating pump.

- Discharge through the centrifugal pump is uniform.

- Performance of centrifugal pump is superior than the reciprocating pump.

- Torque is uniform for centrifugal pump.

- The efficiency of centrifugal pump at low heads is quite high.

- It can be used for lifling high viscous fluids like oil, paper pulp, sugar molasses, etc.

- There is no danger of separation and cavitation of liquid in the pump.

- For same capacity and energy transfer the gross weight of centrifugal pump is less than the reciprocating pump.

Applications of Centrifugal Pumps

- For agricultural and irrigation purposes.

- Thermal power plants.

- For drainage and drinking water system.

- Process industries such as paper pulp, chemicals, petrochemicals, pharmaceuticals to convey raw material and finished products from one place to another place.

- Food industries

- Water Purification plants.

- Oil and gas industries for purification purposes.

- Metal treatment processes like electroplating, anodizing etc.

- Textile industries for bleaching of fabrics.

Volute Centrifugal Pump

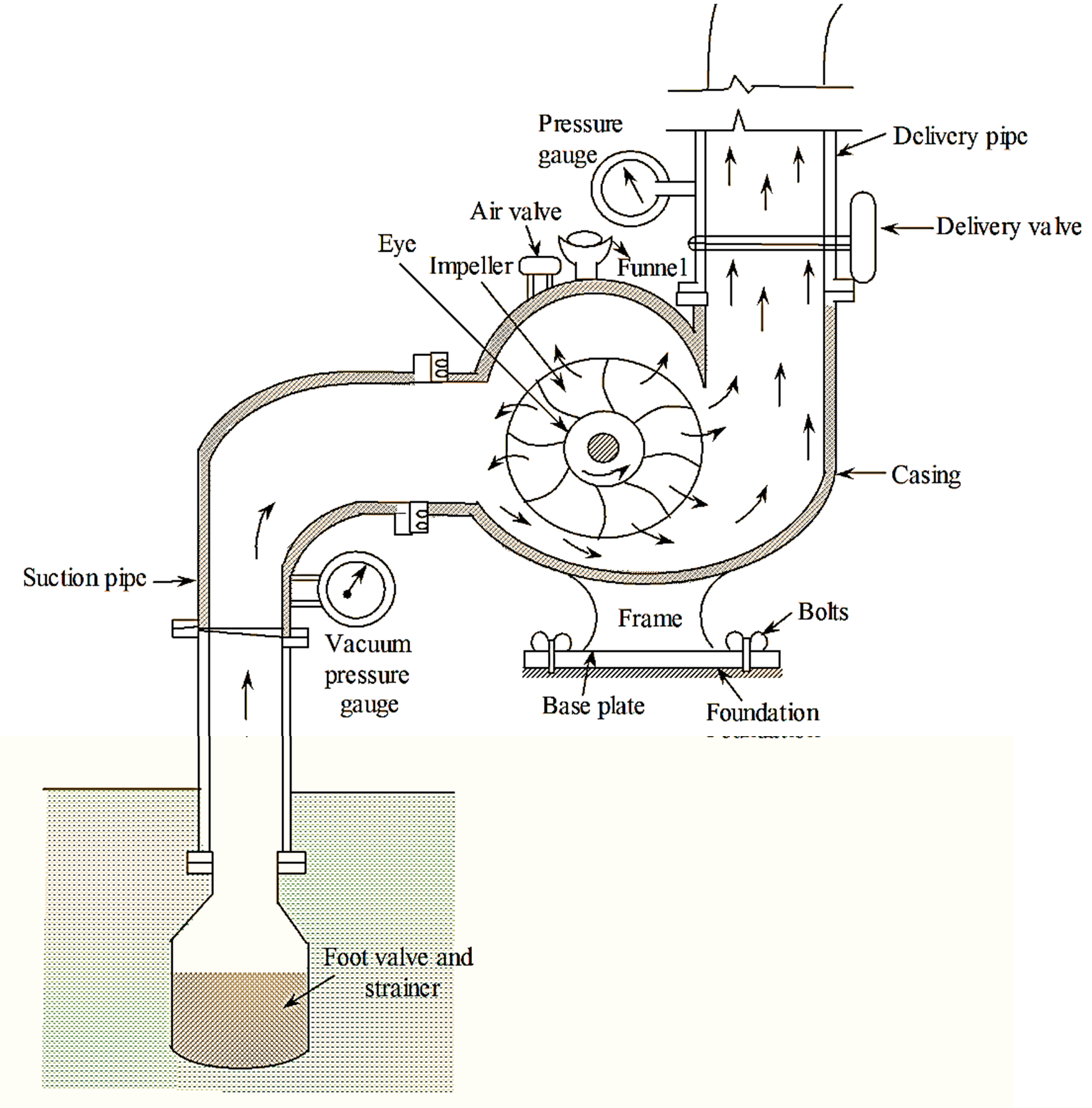

Figure 3: Volute Pump.

In ‘volute type’ of centrifugal pump, the casing is of spiral shape that gradually increases the area of flow (Figure 3). As shown in figure, the liquid is sucked through the centre of the impeller, which is rotated by motor.

When the impeller starts rotating, liquid present at eye of the impeller is pushed towards the periphery. The liquid flows through a gradually widening channel. As a result of it, its velocity reduces with corresponding increase in pressure. Thus, volute chambers are the ducts alTanged around the impeller that reduce the exit velocity and convert velocity head into pressure head.

Diffusion Centrifugal Pump

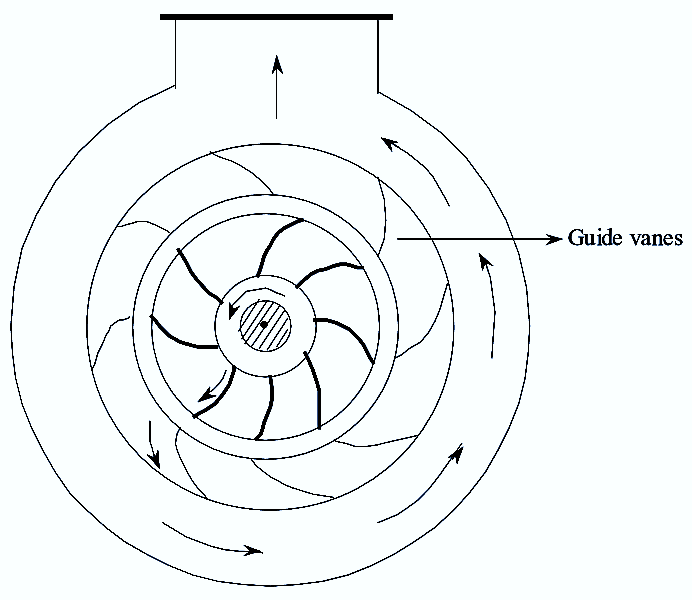

Figure 4: Diffusion Pump.

In this type of pump, a diffusion ring surrounds the impeller (Figure 4). The ring consists of series of guide blades or diffusers. Liquid from the impeller eye is forced towards the periphery through the openings between the guide blades. When the liquid flows through the diverging passages between the guide blades, its velocity reduces with corresponding increase in the pressure. As a result, the velocity head is converted to pressure head. Diffusion pumps are also known as turbine pumps as these resemble Francis turbine with inlet guide blades