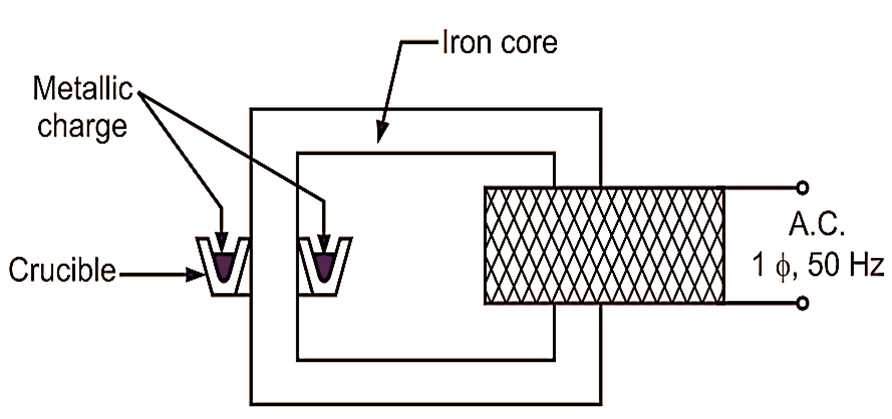

Fig. 1: Core Type Induction Furnace.

Construction of Core Type Induction Furnace

It consists of magnetic core having thin laminations of silicon steel. The primary is wound on one limb and a crucible type non-conducting ring is provided on the secondary. The crucible provides housing for the metal to be heated. The crucible is made-up of ceramic material so that it can withstand high temperatures. The core of the transformer is designed such that it does not saturate even if high current is passed.

Working of Vertical Core Type Induction Furnace

First of all the charge in the form of different sizes is poured into the crucible. Due to these different sizes of the material, there is a possibility that the secondary circuit may not be complete, to avoid it, this more conductive material of powdered form is put on the pieces of material.

When A.C. supply is given to the primary, alternating flux is produced which links with the secondary. So e.m.f. is induced in the charge itself. Heavy current is circulated through the top powdered layer of conductive material and heat is produced in the top layer of charge which is transferred to the bottom layer of charge.

Disadvantages of Core Type Induction Furnace

- Due to irregular shape of the charge, magnetic coupling between primary and secondary is poor.

- High leakage reactance due to poor magnetic coupling causes poor power factor.

- To avoid low power factor low frequency supply is necessary. So low frequency generator is required to be installed. The overall cost of the furnace is increased.

- Pinch effect may occur which causes open circuit to secondary side.

- Crucible is of odd shape and it is difficult to manufacture.

Pinch-off effect in core type Induction furnace

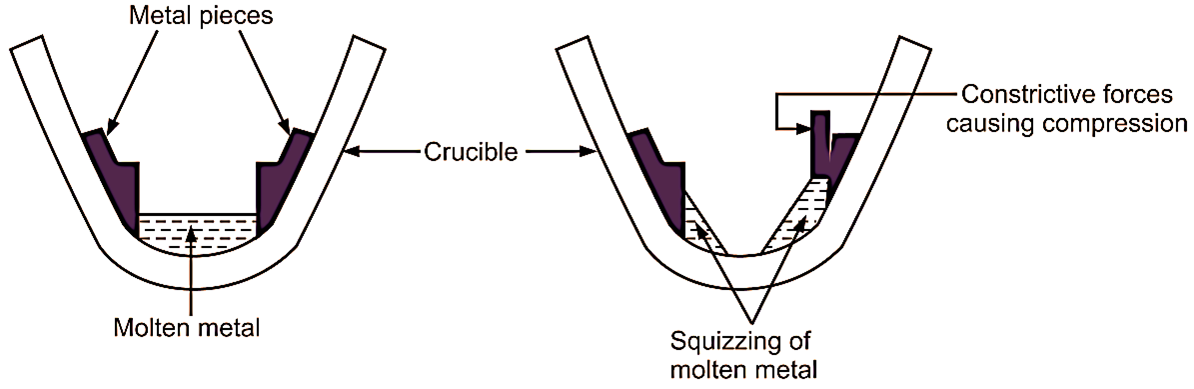

Fig. 1: Pinch-off Effect

The magnetic coupling between primary and secondary is very poor, resulting in high leakage reactance and low power factor To overcome this difficulty frequency is kept small (as low as 10 Hz).

The electromagnetic forces produce turbulence in the molten metal. This turbulence effect is dependent on frequency and current density. The turbulence effect is severe at high values of frequency and current density.

Hence, frequency is kept upto 10 Hz and current density is 5 amp/mm2. The current flowing around the melt interacts with the alternating flux and produces constrictive forces on a section of the metal. This squeezes the melt and results in complete interruption of the section circuit. This effect is known as Pinch-off effect.