In Dynamometer type instruments, the permanent magnet used in moving coil permanent magnet instruments is replaced by either one or two fixed coils which carry the current to be measured (or current proportional to voltage to be measured) and which are connected either in series or in parallel with the moving coil. The coils are usually air cored, the use of iron being usually avoided in such instruments owing to its introduction of hysteresis and eddy current and other errors.

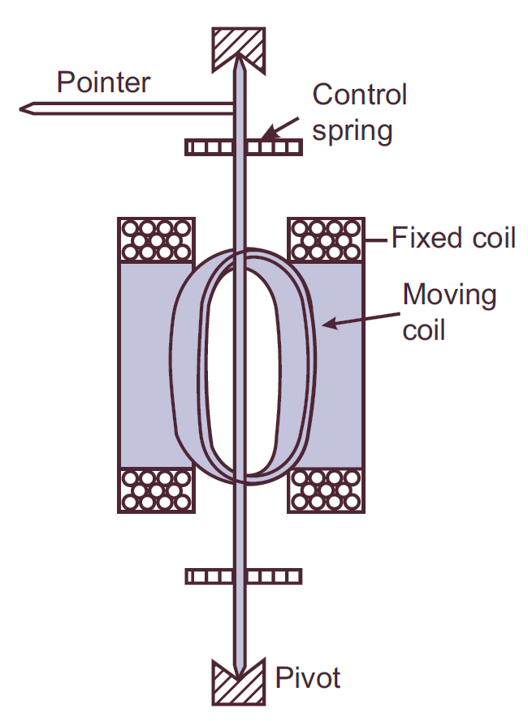

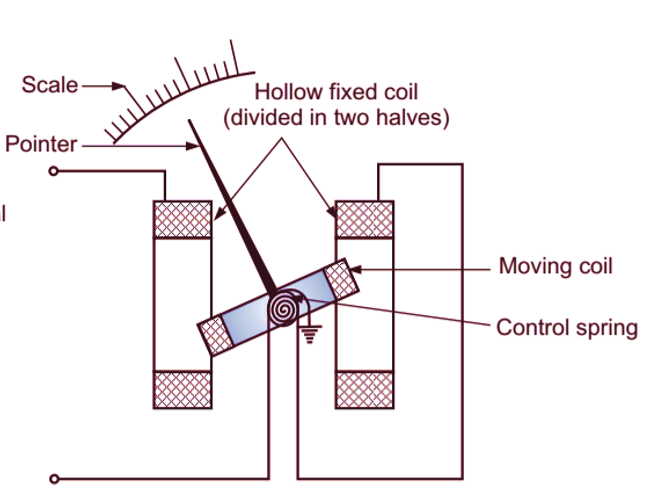

When the instrument is used for A.C. measurements, the general arrangement is shown in Fig. 1. and the connection diagram is shown in Fig. 2.

Fig. 1: Dynamometer type instrument (Actual construction)

Fig. 2: Dynamometer type instrument (Schematic connections)

Dynamometer type instrument Ammeter and Voltmeter

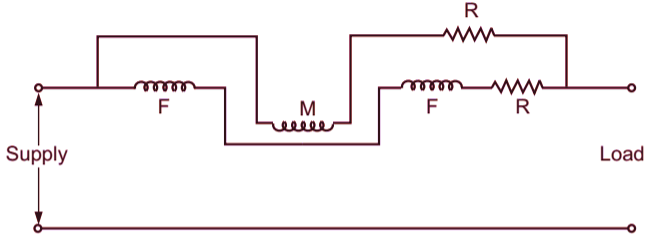

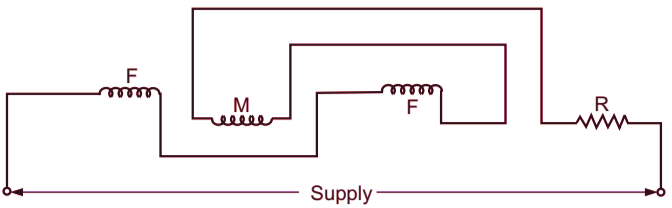

Fig. 3 (a) shows the connections of a dynamometer, ammeter, and Fig. 3 (b) that of a voltmeter. The torque of the instrument is dependent upon the strengths of the magnetic fields of both fixed and moving coils i.e. in an ammeter the torque is roughly proportional to the current squared and in voltmeter to the voltage squared.

(a) For high current ammeter

(b) As voltmeter

Fig. 3: Dynamometer-type instrument connections.

Advantages of Dynamometer type instrument

- It is free from hysteresis and eddy current errors, but is used only as voltmeter or ammeter for precision measurements. It is generally used as a wattmeter

- It can be used for D.C. as well as A.C. measurements.

- It has a fairly high degree of accuracy.

Disadvantages of Dynamometer type instrument

As compared to permanent magnet instruments, it has the following disadvantages:

- As there is no iron core in the fixed coils, the field intensity is very weak. Therefore, to obtain necessary deflecting torque, large number of ampere turns must be used on moving coil. This makes the moving element heavy and the power loss is high. The torque to weight ratio is small and frictional error is high.

- It is comparatively costly.

- Deflecting torque being proportional to square of voltage or current, the scale is not uniform.

- Operates with weak magnetic field because the coils are air cored