In this topic, you study Electric Motor – Diagram & Working.

An electric motor is a machine which converts electrical enegy into mechanical energy and so its function is exactly the reverse of that of a generator.

In fact, the same DC machine can be interchangeably used as a generator or motor depending upon whether the electrical energy is supplied by it or supplied to it.

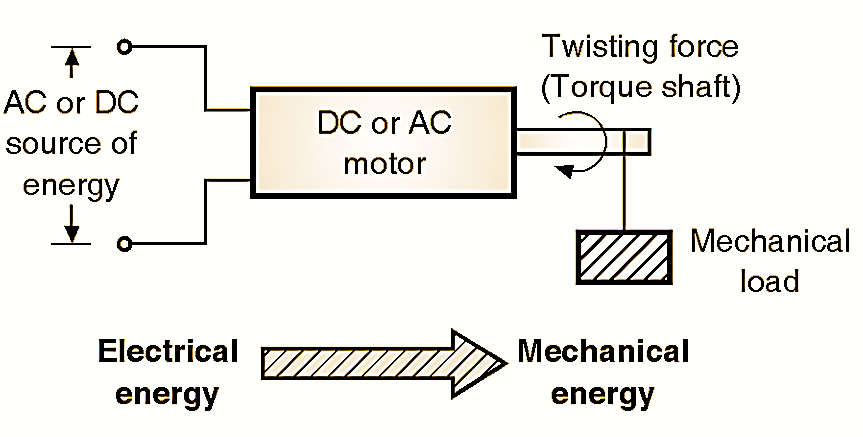

Most electric motors operate on the principle of generation of a twisting force produced due to the interaction between the magnetic field and the winding current of the motor (see Figure 1).

Figure 1: An electric motor converts electric energy into mechanical energy.

Working of an Electric Motor

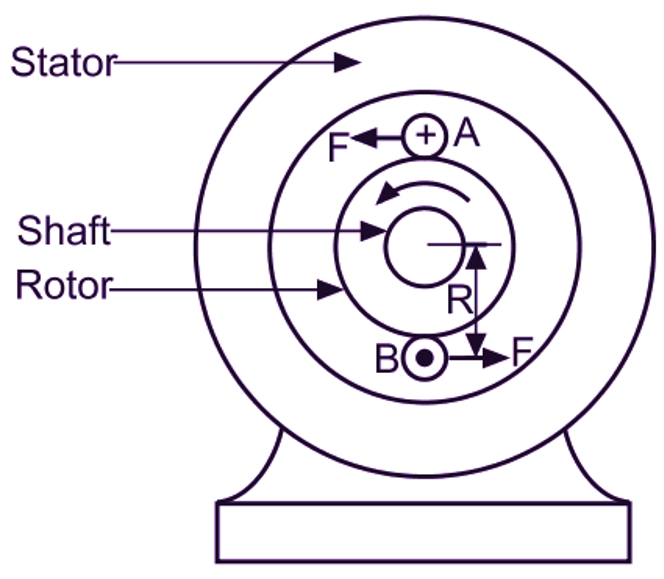

We know that when a conductor carrying a current is placed in a magnetic field, it experiences a mechanical force. The action of electric motor is based on this principle. It has some suitable mechanical arrangement to utilize this force in producing the motion(rotation) of the conductors as illustrated in Fig. 2.

Fig. 2. Production of torque in a motor

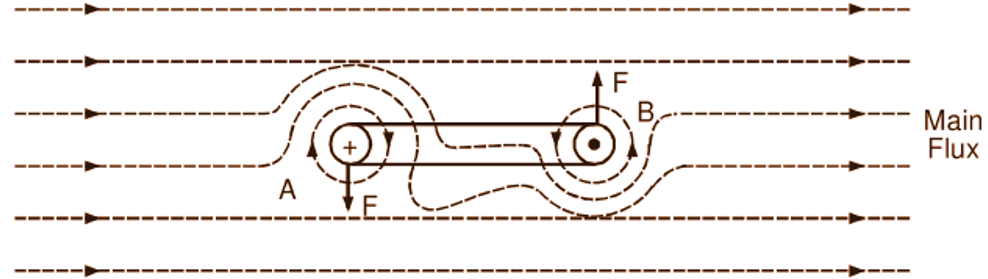

The turning or twisting moment of a force about an axis is known as torque. It is measured by the product of the force (F) and the radius (R) at which this force acts, the unit being newton-metre (Nm). The production of the torque requires the interaction of two sets of magnetic fields produced by two sets of windings both carrying currents. One set of windings is placed on the stationary outer member called stator and the other set on the rotating member called rotor. The principle is illustrated in Fig. 3 which shows a rotating member in the form of a coil (AB) free to rotate about its axis in a uniform magnetic field produced by the current-carrying winding on the outer stationary member.

Fig. 3: Principle of torque production in a motor

If this coil is supplied with current directly or by induction, the magnetic flux associated with this current will interact with the main magnetic flux resulting into a motion of the coil due to force and subsequent torque experienced by each coil side. With the current in the direction as indicated, the motion of the coil will be in an anticlockwise direction. This is obvious from the resultant flux pattern shown in Fig. 3. The direction of the force (F)which will be experienced by each coil side can also be found by using Fleming’s left hand rule.

“Fleming’s Left-Hand Rule : Arrange the first finger, the second finger and the thumb of your left hand mutually at right angles to one another. Point the first finger in the direction of the field and the second finger in the direction of the current, then the thumb will point in the direction of the force on the conductor”.

The principle of torque production is basically the same whether the current producing the two fields originate from a.c. or dc supplies. In all the commonly encountered varieties of practical electric motors, either or both the sets of windings mentioned above are excited by alternating or direct current. When direct current (dc) is supplied to both rotor and stator windings, the motors are known as dc motors. On the other hand, in induction motors, alternating current is supplied directly to the stator winding and by induction (i.e. by transformer action) to the rotor winding. In synchronous motors, alternating current is supplied to the stator winding and direct current(dc) to the rotor winding. We shall begin our study of electric motors firstly with the study of dc motors.

Types of Electric motor

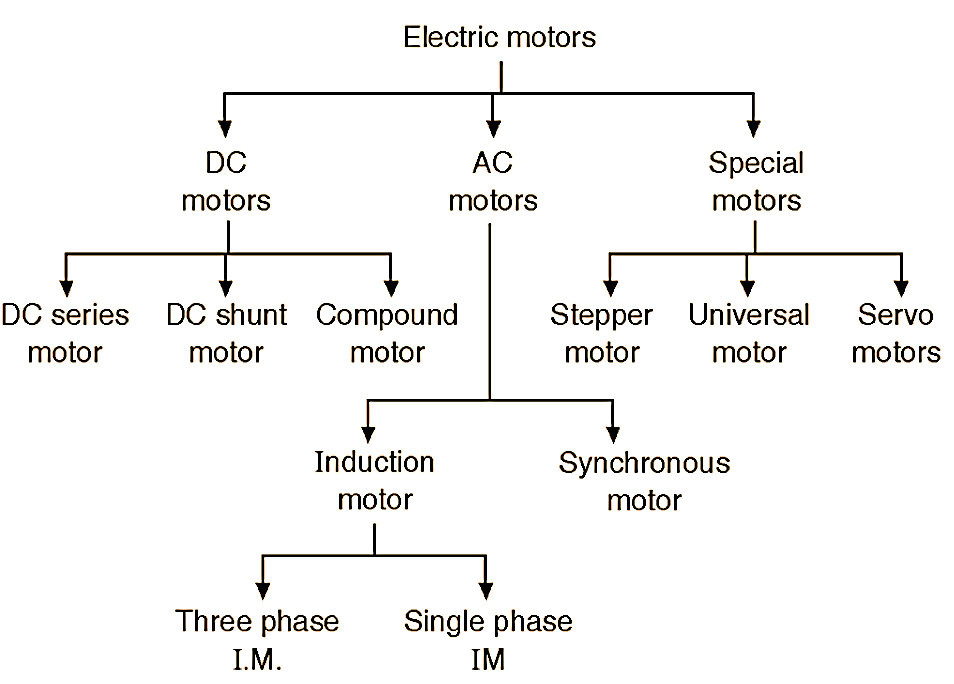

Fig. 4: Classification of Electric motors

Electric motors are broadly categorized as DC motors and AC motors depending on the type of energy source used. Electric motors produce linear or rotary force (torque). Fig. 4 shows the classification of motors. We can classify the electric motors on the basis of the following parameters:

- Power source type (AC or DC).

- Internal construction.

- Applications.

- Type of motion output (Continuous or steps).

- Brushed or brushless.

- Number of phases (Single phase, three phase).

Applications of Electric motor

Present-day large scale utilization of electrical energy is possible only because of the development of the various types of electrical motors to suit different industrial and domestic applications. Every modern industry of today incorporates such motors either into its products, or its manufacturing processes. The number of homes equipped with domestic appliances using electric motors is also increasing very fastly. The study of electric motors is, therefore, of vital importance. Among the different types of electric motors that are available, induction type a.c. motors are most widely adopted in industrial drives. Even then, use of dc motors becomes essential in many industrial applications due to their typical performance characteristics and precise speed control over a wide range. Hence, various aspects like operating principle, types, starting, reversal of rotation, speed control and industrial applications of dc motors.