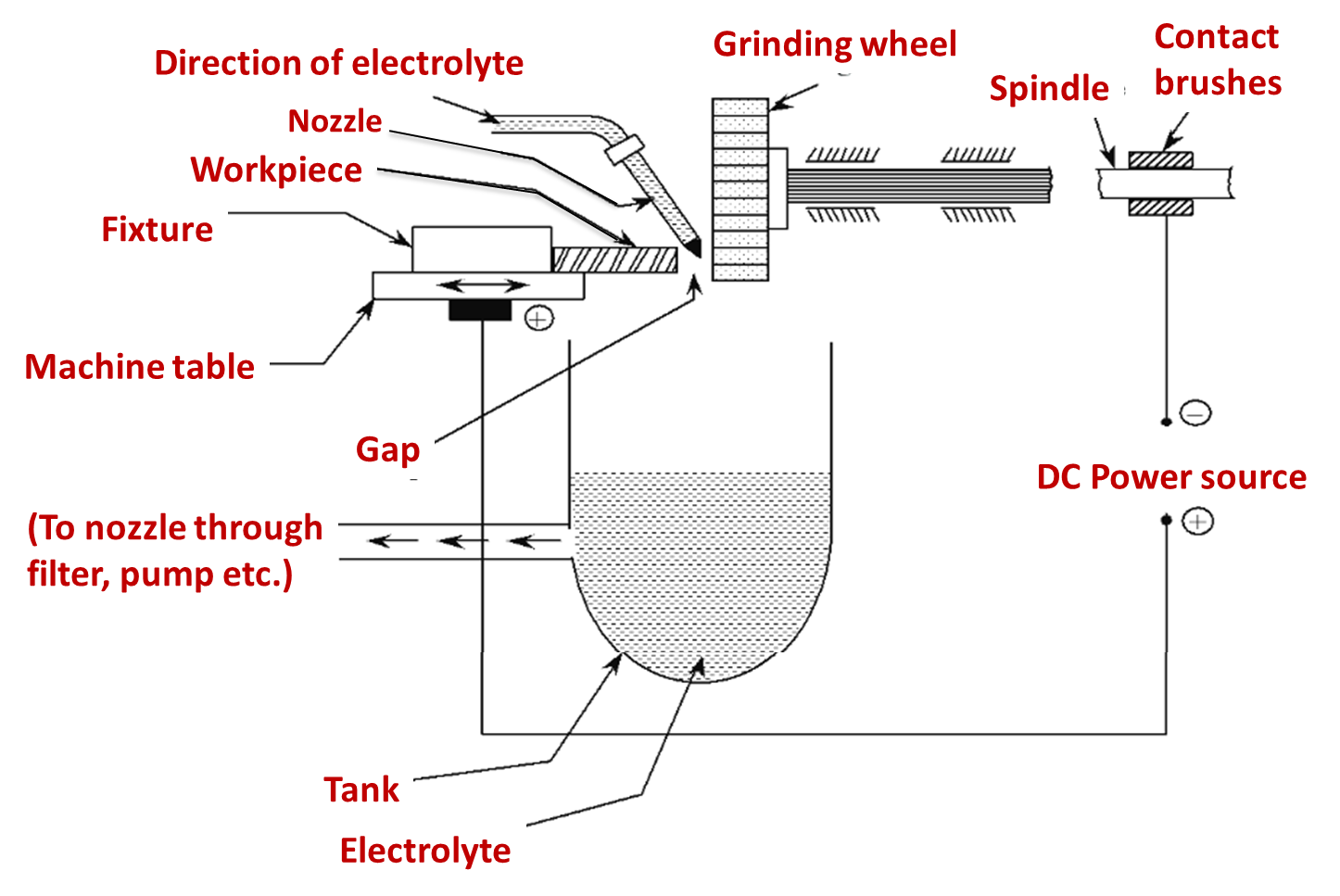

Figure 1: Electrochemical Grinding (ECG)

Depending upon the improvement of electrochemical machining process, the electrolytic process is developed. In the electrochemical grinding process, the removal of material takes place by electrochemical deposition (90

Advantages of Electrochemical Grinding

- Electrochemical grinding provides excellent surface finish ranging from 0.05 to 1 µm.

- It provides better accuracy (0.01 mm) by selecting the wheel grit size and abrasive particles accurately.

- Insignificant tool wear.

- No need of “wheel dressing” repeatedly, hence it saves a considerable amount of time.

- In contrast to the normal grinding, Electrochemical Grinding requires small amount of cutting force on the workpiece.

- Machined surfaces are free from cracks.

- Structure of workpiece material remains unchanged.

Disadvantages of Electrochemical Grinding

- The rate of metal removal is very less and is about 15 mm3 /sec.

- Initial cost of the system is very high.

- It requires more power for performing the operation.

- It machines only the electrically non-conducting materials.

- This process requires frequent safety precautions in contrast to the corrosion by electrolyte.

Applications of Electrochemical Grinding

- Electrochemical Grinding process is more widely used for grinding carbide cutting tools.

- Electrochemical Grinding specifically employed for grinding delicate components which involves honeycomb, thin walled tubes, skins, hypodermic needles, etc.

- This also used for grinding hard, tough, stringy, work hardenable or heat-sensitive materials.