Electroslag welding is used to join two thick metal plates without edge preparation. The plates to be welded are held in vertical position keeping some gap between edges.

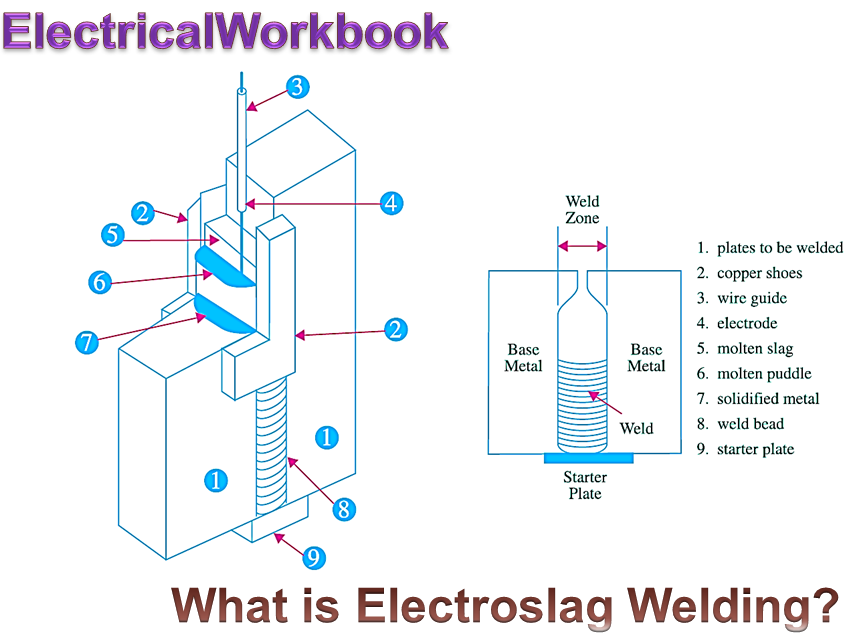

Fig. 1: Electroslag welding.

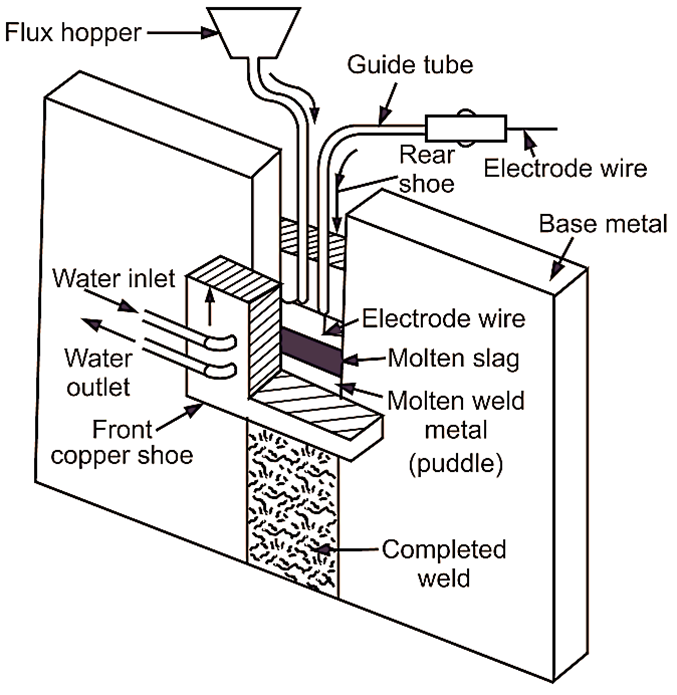

In Electroslag welding process no arc is established but weld is completed by heat of molten flux, which melts the consumable metal electrode and surface of base metal to form weld material. Electroslag welding consists of AC power supply, suitable mechanism for feeding electrode, hopper to carry flux and rail in vertical with water-cooled shoe (Figure 1). To start the weld flux is passed to joint through hopper, current is switched on which passes to electrode through flux. The resistance offered by the flux to the flow of this current creates heat and melts the flux, which in turn heats and melts the electrode and base metal. Water-cooled copper shoes slide the upward and solidify the weld. As the solidification of weld metal proceeds upwards more slag is added in hopper. The process is continuing till whole length of plate is welded. The electrode wire used is solid type or flux coated. Process can be used to form butt joints in heavy steel forgings, castings and heavy structures.

Advantages of Electroslag Welding

- It has an advantage that it can weld the workpiece thickness upto 45 cm easily and more economically than other types of welding processes.

- It has no need to special weld joint edge preparation.

- In the time of electroslag welding the arc is invisible, so this welding process gives spatter free welding joint.

- Welding in the flat and overhead positions is also possible with this technique and equipment.

- Aluminium or other special steels can also be welded in successfully.

- Residual stresses and distortion produced is less.

Disadvantages of Electroslag Welding

- Costlier than submerged arc welding.

- There are some chances of hot cracking.

- Welding is carried out in vertical up hill position.