Grinding is defined as the process of removing metal in small quantities, by using an abrasive wheel called grinding wheel. In order to bring the workpiece to required size and shape, to obtain quality of work surface and dimensional accuracy grinding process is used. The metal removal is carried out in small quantities, which bring the machining process to desired accuracy. The microscopic examination of removed chips are similar to that of machined metal chips. The unique surface finish and accuracy in size is obtained by the grinding process.

This process, also removes material in a small area where machining is impossible. It is an efficient method of removing material from the machine parts, which are hardened. Due to high hardness of abrasives, complex profiles can be produced with extremely low pressure. Extremely smooth finish at bearing surface can be produced only by this process.

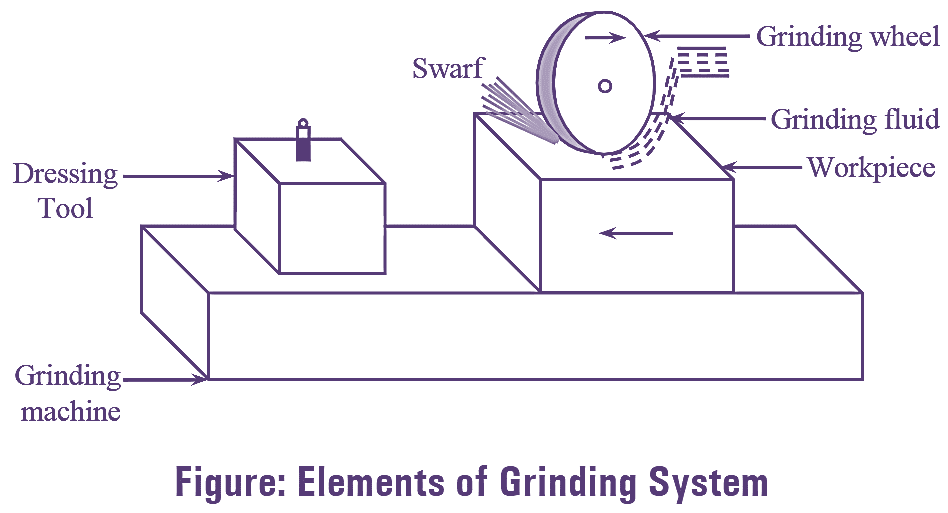

Elements of Grinding

The basic elements of a grinding process include (see Figure 1),

1. Workpiece Material :

Workpiece being ground is firmly held against the rotating grinding wheel, to remove the unwanted metal.

Various parameters of workpiece such as shape, size, stiffness, hardness, chemical and thermal properties have impact on the quality of grinding.

2. Grinding Wheel :

It is the cutting tool, made up of abrasive materials, which should be harder than the workpiece material. The grinding wheel should possess the following properties for better accuracy and surface finish,

- High hardness and stiffness

- Low heat sensitivity

- High wear resistance

- Better grain size

- Good structure of bond

- Highly resistant to thermal and chemical effects.

3. Grinding Machine :

The machine structure provides the static and dynamic constraints between the tool and the workpiece. Type of machines to be selected depends upon the type of operations to be performed.

A perfectly designed grinding machine should experience less vibrations and provide high accuracy movements. Thus, the specification, design and manufacturing of the grinding machine, influence its performance.

4. Kinematics :

Kinematics of grinding process includes the geometry and motions governing the movement or engagement between the workpiece and grinding wheel.

5. Dressing Conditions :

The factors which affect the dressing conditions are type of tool, cooling medium, lubrication, speed and feed, maintenance, etc.

6. Grinding Fluid (Coolant) :

Grinding fluid is used to reduce the wheel wear, cool the workpiece and flush away the swarf (fine chips and abrasive particles). Flow rate, velocity, pressure, physical, chemical and thermal properties of grinding fluid affects its effectiveness.

Advantages of Grinding

- It can be employed for materials, which are too hard to machine by other processes.

- Better surface finish and smooth surfaces can be obtained.

- The pressure required during grinding process is less.

- Complex profiles can be produced accurately.

- The grinding wheels have self sharpening property.

- High cutting speeds can be employed.

- High material removal rate.

- The abrasives can sustain at high temperatures.

- High dimensional accuracy up to ± 0.02 mm can be obtained.

Disadvantages of Grinding

- High cost of tool, power and labour is required.

- The value of the operation lies in the quality of finish obtained and accuracy of the product, but not in the amount of material removed.

- The time taken in removing a certain quantity of stock through grinding operation is more.

- The grinding wheels wear out more quickly than other types of cutting tools.

- Incorrect grinding leads to glazing and clogging.

Applications of Grinding

- It is used for sharpening the cutting tools.

- It is used for grinding threads.

- It is used for machining hard surface, which are difficult to machine by HSS and carbide tools.

- It is used for rapid stock removal from the workpiece.