The hydraulic accumulator stores excess hydraulic energy and on demand makes the stored energy available to the system. The function of accumulator is similar to the function of flywheel in the IC engine/steam engine or capacitor in the electric circuit. Since accumulators are having the ability to store excess energy and also having ability to release the energy to system when system is in bad need of energy, the hydraulic systems using accumulators are most efficient systems because there is very little energy loss.

Types of Hydraulic Accumulator

There are three basic types of hydraulic accumulators:

- Dead weight accumulator.

- Spring loaded accumulator.

- Gas pressurised accumulator.

Dead Weight Accumulator

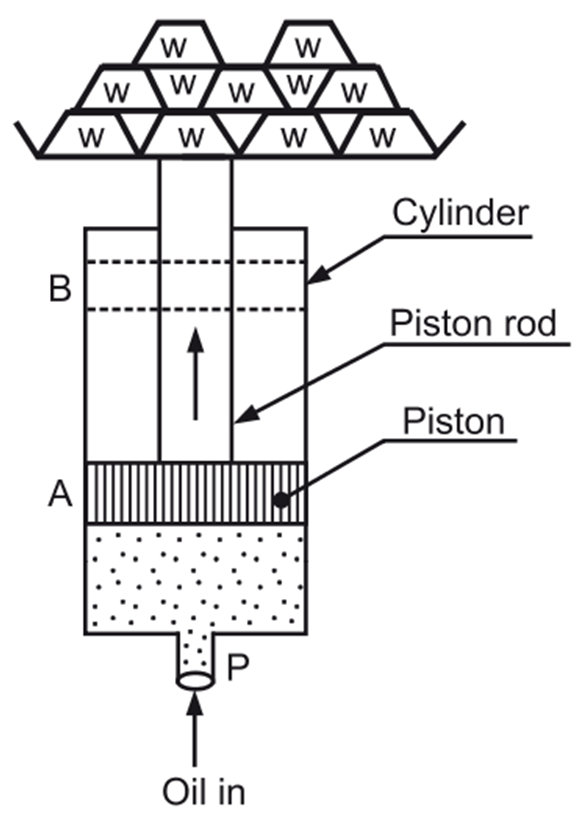

Figure 1: Dead Weight Accumulator.

This accumulator consists of a sliding piston in a cylinder. The piston rod diameter is much bigger. The oil under pressure usually from pump enters into the cylinder through port P (see Figure 1). The pressurised oil forces the piston upwards, until it reaches position B. Dead weight W kept on top of piston rod is in the form of concrete/steel/other heavy material. This weight is chosen to exert a predetermined pressure on the fluid entering the cylinder. When piston reaches at point B, the accumulator is said to be ‘fully charged’. Now the oil in the cylinder is having ‘pressure energy’ due to dead weight W acting on it.

The energy is stored by oil in cylinder. Now when the system in which this accumulator is connected, it demands hydraulic oil under pressure, then pressurised oil starts flowing out of port P. When oil starts going out the piston will move down. Due to dead weight pressure of oil will be maintained.

Advantages of Dead Weight Accumulator

- Pressure remains constant for full stroke due to dead weight.

- This accumulator can supply large amount of oil under pressure.

Disadvantages of Dead Weight Accumulator

- These accumulators are bigger in size and occupy more space and are bulky.

Spring Loaded Accumulator

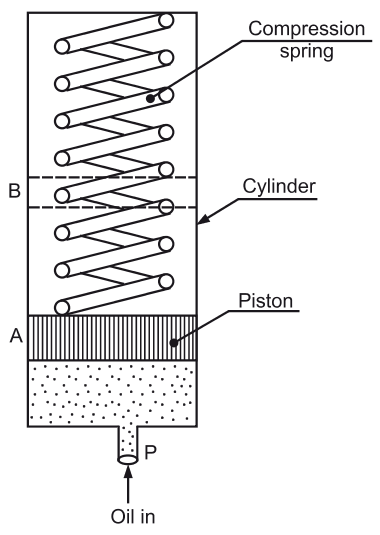

Figure 2: Spring Loaded Accumulator

This is a modified version of dead weight accumulator. In this accumulator, there is a spring loaded piston which moves up and down in cylinder. The oil under pressure usually from pump enters into the cylinder through port P. This oil forces the piston upwards causing the spring to compress. The top dead position of the piston shown by point ‘B’ in the Fig. 2 will be decided by full compression length of spring.

When piston reaches point B by fully compressing the spring, the accumulator is said to be ‘fully charged’. Now the oil in the cylinder will be having ‘pressure energy’ due to resilience of the spring.

Now when system in which this accumulator is connected, if demands hydraulic oil under pressure, then spring starts expanding thereby pushing the piston downwards and pressurised oil will come out of the port ‘P’. When spring will be fully expanded (reaches to its free length), the pressure of oil coming out of the accumulator will be almost minimum.

Advantages of Spring Loaded Accumulator

- All moving parts are enclosed in the cylinder. No parts outside.

- Compact design i.e. if we use compound spring, the design will be more compact and handy.

Disadvantages of Spring Loaded Accumulator

- When spring starts expanding it gives off the stored energy very quickly. And hence as spring starts expanding the pressure of oil below the piston goes on decreasing. So we cannot get uniform pressure in a stroke.

- When spring is fully compressed, its length is called solid length. Due to this solid length, the stroke of piston becomes limited, as compared to dead weight accumulator

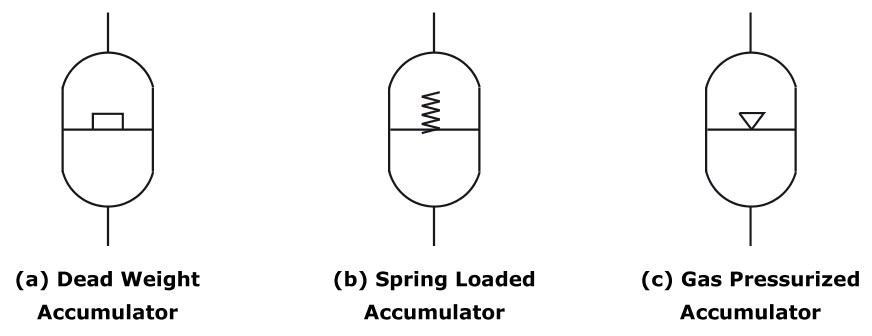

Symbols of Hydraulic Accumulator

Figure 3: Symbol of Hydraulic Accumulator