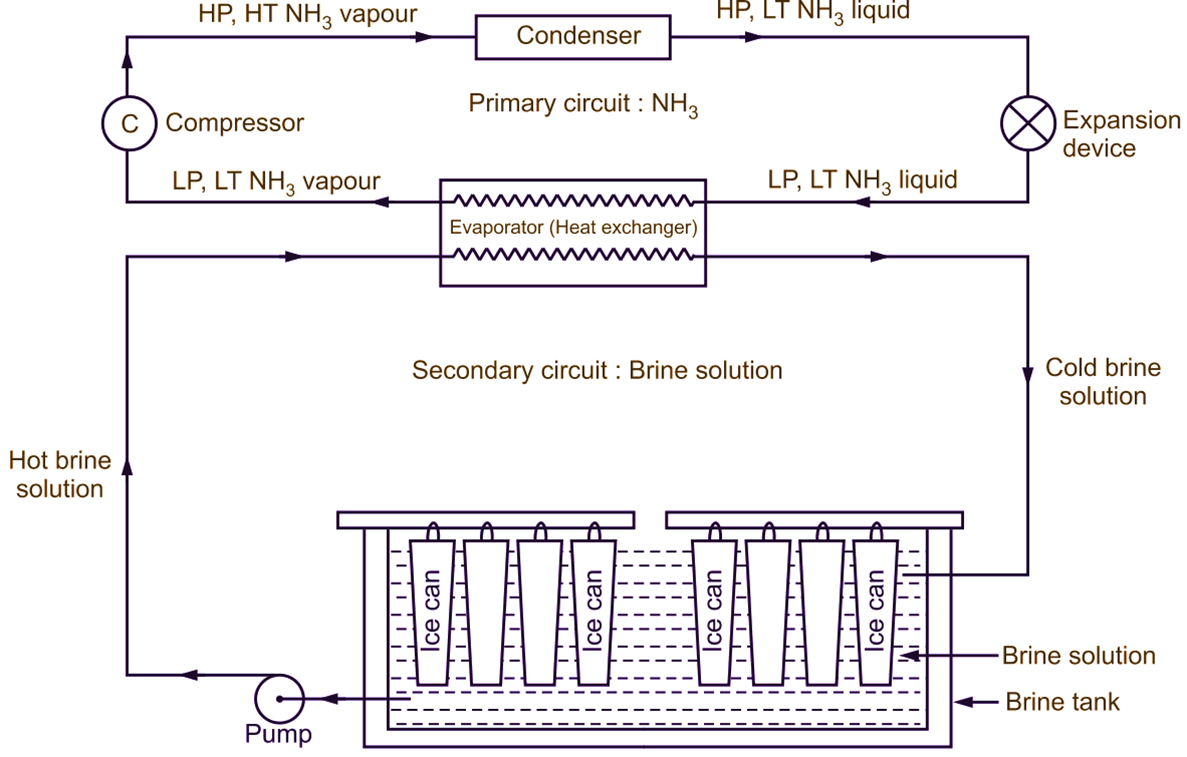

Ice plant consists of two circuits: Primary circuit and Secondary circuit.

In primary circuit, ammonia is used as refrigerant, whereas in case of secondary circuit, brine solution is used as refrigerant. As ammonia (primary refrigerant) is toxic in nature, so it should not come in direct contact with the water. Therefore, a secondary refrigerant (brine solution) is used. This brine solution is circulated around the galvanized iron cans containing the water circulating with the help of brine pump. Brine solution takes the heat from the water to convert it into ice. This heat absorbed by brine solution is ejected to primary refrigerant (ammonia) in the heat exchanger.

Figure 1: Ice Plant.

Construction of Ice PIant

Commercial ice is produced by freezing water in standard cans placed in rectangular tank insulated from all sites. The tank is filled with chilled brine, which is continuously circulated in secondary circuit. Brine tank is fabricated from 7 mm thick mild steel plates. The depth of brine tank and insertion of ice cans are so adjusted that, brine level is at 25 mm more than the water level in the cans. Insulated wooden lids are provided to cover the top to facilitate the removal of ice cans. Ice cans are tapered by about 10 to 12 mm in their height for easy removal of ice produced from the Ice cans. To get clear transparent Ice, the water in the can is agitated by the use of low pressure air through the tubes suspended from the top.

Working of Ice PIant

Primary circuit consists of four basic components, namely compressor, condenser, expansion device and evaporator. The vapour ammonia coming out from the evaporator is compressed in the compressor and gets converted into high pressure, high temperature vapour ammonia refrigerant. This high pressure, high temperature vapour ammonia (refrigerant) is condensed in condenser and gets converted into high pressure, low temperature liquid ammonia refrigerant. This high pressure, low temperature liquid ammonia refrigerant is made to pass through expansion device, where it and gets converted into low pressure, low temperature liquid ammonia refrigerant. This low pressure, low temperature liquid ammonia refrigerant comes in the evaporator, where it absorbs heat from brine solution and gets converted into low pressure, low temperature vapour ammonia refrigerant and then enters to compressor of primary circuit. Also, we can see that, the brine solution flowing through the secondary circuit is cooled. This cooled brine solution is circulated around the water cans to absorb heat from water. Now, the same cycle is repeated again and again till the ice of desired temperature is formed.