Capacity of automobile air conditioning systems: 1 TOR to 4 TOR.

Refrigeration cycle used: Vapour compression cycle.

Refrigerant used: R – 134a.

The system used for automobile air conditioning works on the same principles that other air conditioning being used. The major problem associated with automobile air conditioning is running speed of compressor. usually ground AC systems are given electrical input to compressor, whereas, in automobile, compressor is driven by engine shaft. While installing AC in the automobile, the compressor is mounted above the engine and it is driven by belt drive powered from front end of the engine. The condenser is mounted ahead of car radiator. The cooling coil and the blower are usually located under dashboard.

Construction and Working of Automobile Air Conditioning System

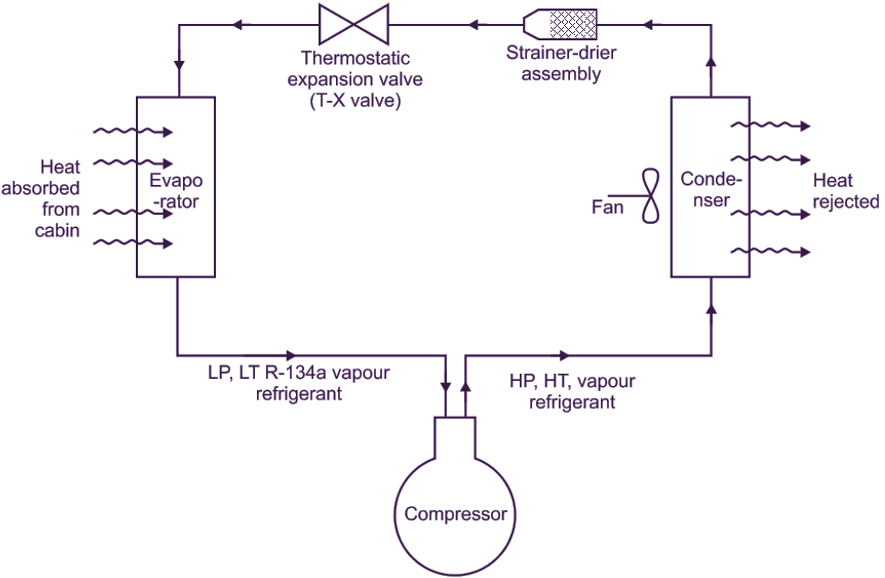

Fig. 1: Automobile air conditioning system

Compressor: Low pressure, low temperature R – 134a vapour refrigerant entering the compressor is compressed to become high pressure, high temperature R – 134a vapour refrigerant. This vapour refrigerant is then circulated along with lubricant oil to the condenser.

Condenser: As the high pressure, high temperature vapour refrigerant travels through the condenser, heat is released to the comparatively cold ambient/atmospheric air passing over the condenser tubes condensing the vapour refrigerant into liquid refrigerant.

Strainer-drier assembly: This high pressure, low temperature liquid refrigerant then flows through the strainer-drier assembly (also known as filter-drier assembly). Strainer traps the impurities, contaminants and foreign particles etc. and removes them from the refrigeration system. Drier removes moisture (i.e. water vapour associated with refrigerant) from the refrigeration system.

Expansion valve: High pressure, low temperature liquid refrigerant flows through the thermostatic expansion valve, where its pressure is decreased due to its flow through a small variable or fice providing restriction. Thus, the refrigerant becomes low pressure, low temperature vapour refrigerant.

Evaporator: Refrigerant is now low pressure, low temperature liquid refrigerant, which enters the evaporator coil. The heat from the cabin is blown over the surface of evaporator coil, through which, low pressure, low temperature liquid refrigerant flows. This low pressure, low temperature liquid refrigerant absorbs the latent heat of vapourization from the cabin and gets vaporized. Due to heat rejected to refrigerant, cabin becomes cooled. The low pressure, low temperature vapour refrigerant is then pulled into the compressor through the evaporator. This completes one cycle. Same cycle is repeated again and again, till desired temperature in cabin is achieved.