The main types of insulators used for overhead lines are

- Pin Insulator.

- Shackle insulator

- Suspension Insulator or disc or string insulators.

- Strain or tension Insulator.

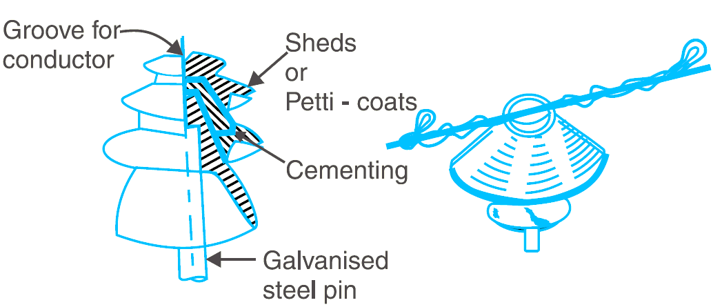

Pin Insulator

The pin insulator supports the wire at the top or at the one side as shown in Fig. 1. It is supported with a steel bolt or pin which is fixed on the cross arm. The conductor is first placed in the groove at the top of the insulator and then attached to the insulator by tying it with the help of a wire generally of the same material as that of conductor. The pin insulators have some times one, two or three sheds or petticoats for the suitability on telephone line, L.T. lines and H.T. lines respectively.

Uses: Pin type insulators are used for telephone lines, distribution and transmission lines of electrical power up to 33 kV.

Limitation of Pin Insulator

- These are less flexible

- The size become heavy at higher voltages so these are not economical to use above 33 kV line.

Fig. 1: Pin insulator

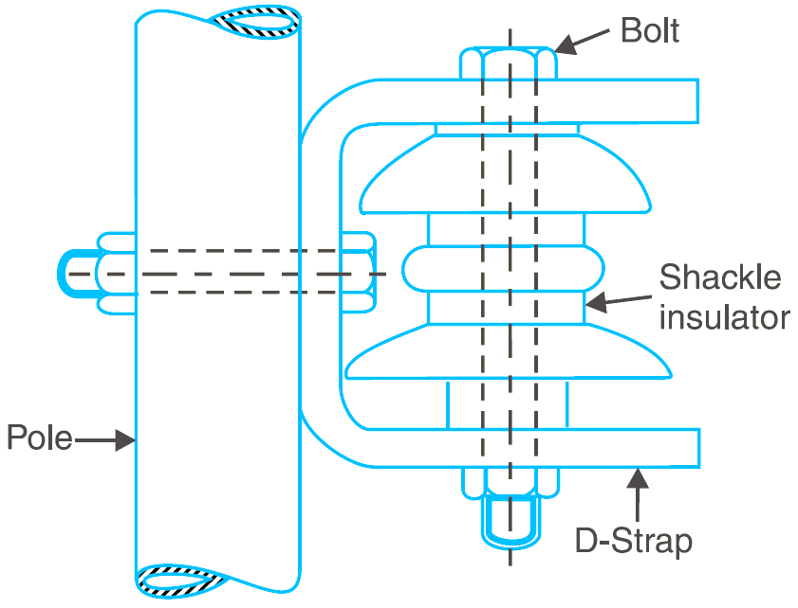

Shackle insulator

The shackle insulators are used to support the wire at dead end, or sharp turns or where the wires take bend at a particular angle as shown in Fig. 2. It has hole in its center and is supported by means of nuts and bolts and a supporting strip.

Uses: These are used at dead end or sharp turns of L.T. lines.

Fig. 2: Shackle insulator

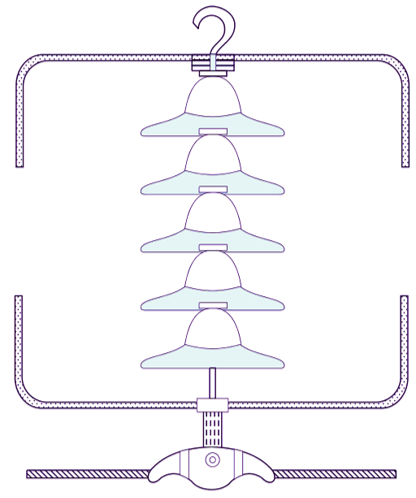

Suspension insulator

These are also known as disc insulators. These are used for H.T. transmission line conductors. It consists of a number of porcelain discs connected in series by metal links in the form of a string. A number of discs can be added to meet the demand of increased voltage of H.T. line. The conductors are suspended at the bottom end of the string as shown in Fig. 3 while the upper end of the string is secured to the tower or pole cross-arm.

Uses: These are generally used for HT. lines above 33 kV.

Fig. 3: Suspension insulator

These insulators are cheap for more than 33kV voltage range. Each disc is designed for approximately I I kV so number of units can be increased in series to meet any voltage requirement ahnve 33 kV. The replacement of disc is easy. So this system is more flexible and frequently used for H.T. lines.

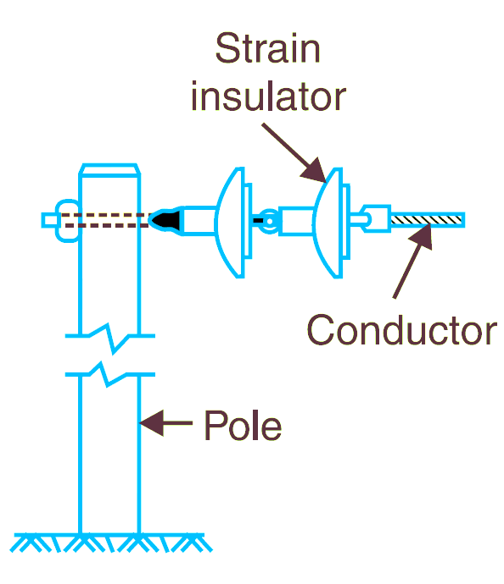

Strain insulator

In order to relieve the line from the strings at the end of line, or sharp ends etc, the strain insulators are used as shown in Fig. 4. Generally these are used in the stay wires. In that case these are termed as stay insulators. For low voltage line egg insulators or shackle insulator can be used as a strain insulator. However for H.T. lines disc or suspension type insulators arc also used. If the strain is much higher in that case two parallel stays are also used. These are used to avoid flow of any leakage current to earth. These are provided at height about 3 m. above the ground level.

Fig. 4: Suspension insulator

What are the reasons for the failure of an insulator in the transmission line?

There could be so many reasons for the failure of an insulator in the transmission or distribution line.

Cracking of an insulator

The thermal expansion of steel, porcelain and cement is different, so as the climatic condition changes, the temperature rises, the expansion is different and uneven which will crack the insulator. So the thermal stresses developed due to seasons i.e. heat, cold or dryness, dampness, rain etc. are the causes of cracking of an insulator.

Defective raw material

If the raw material is defective, on the actual performance the insulator will fail so the defective raw material is also a cause of failure.

Porosity in the material

If during manufacturing some porous are left (low temperature casting) the insulator will puncture in dampness or rain etc. or in long use.

Glazing

If the insulation is not properly glazed the water will stick to its outer surface which will effect its dielectric strength and the insulator will fail.

Flash over

If by any reason there is a flash between the metal parts the continuous slow heating will spoil the insulator and it will fail.

Mechanical stresses

When the insulator is installed and the whole assembly or any one of it is not in equilibrium state, some mechanical stresses will develop because of drawing of line conductors. These stresses will result the mechanical failure of insulator.

Sometimes Short Circuit

Sometimes short circuit due to birds etc. near the insulator happens, it will cause a flashover and failure of the insulator.