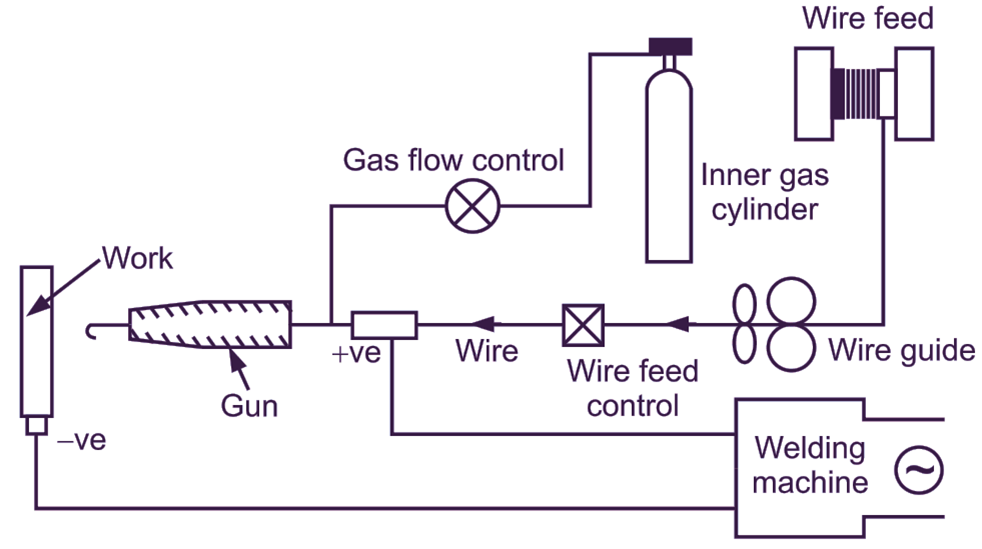

The process involves the welding of metals using a consumable metal electrode in an inert gas atmosphere. The arc is struck between the metal electrode and workpiece (see Fig. 1). The electrode is in the form of continuous wire, which is fed by adjustable feed motor to the weld continuously. A specially designed electrode holder is used which passes inert gas along with the consumable electrode. The inert gas gives the protective shield to electrode, molten weld metal arc and adjacent hot area of base to prevent oxidation. The method is used for welding carbon steels, low alloy steels, stainless steel, aluminum and all alloys. It is not suitable for welding low melting point temperature alloys like lead, tin and zinc. Usually D.C. with reverse polarity is used with MIG for deeper penetration and to get clean weld surface.

Fig. 1: MIG Welding

The inert gas like argon, helium, carbon di-oxide or mixture of these gases may be used to give protective shield.

Advantages of MIG Welding

- Joints can be produced with deep penetration.

- The metal thickness can not vary with this MIG welding process. Thick and thin metals are welded very effectively.

- This welding process is very suitable for large scale production unit because, it can be performed much faster than other types of welding processes like TIG etc.

- Large amount of metal can be deposited on the workpiece.

- The MIG welding process can reduces the welding cost, because it produces neat and clean metal deposit on the workpiece. Spatter free and smooth welding surface is produced, so it is no need to extra cleaning.

Disadvantages of MIG Welding

- Welding equipment is costly.

- Welding in remote place i.e. difficult to reach place is not possible.

- Not suitable for outdoor work.

Applications of MIG Welding

- MIG welding has large use in automobile industry, aircraft parts welding, pressure vessel manufacturing and many other places.

- For welding tool steels, carbon, silicon and low allow steels, stainless steel, aluminium and its alloy, magnesium, nickel and its alloy, copper and its alloy, titanium and so many metals.

- It is used for refrigerator parts manufacturing.