There are two types of pressure thermometers:

- Liquid pressure thermometer.

- Vapour pressure thermometer.

LIQUID IN GLASS THERMOMETER (LIQUID PRESSURE)

Operating Range: up to 300°C.

Method used: Expansion of Liquids.

Working principle of Liquid in glass thermometer

If temperature increases, liquid expands in volume. This change in volume of liquid is directly proportional to change in temperature.

Construction of Liquid in glass thermometer

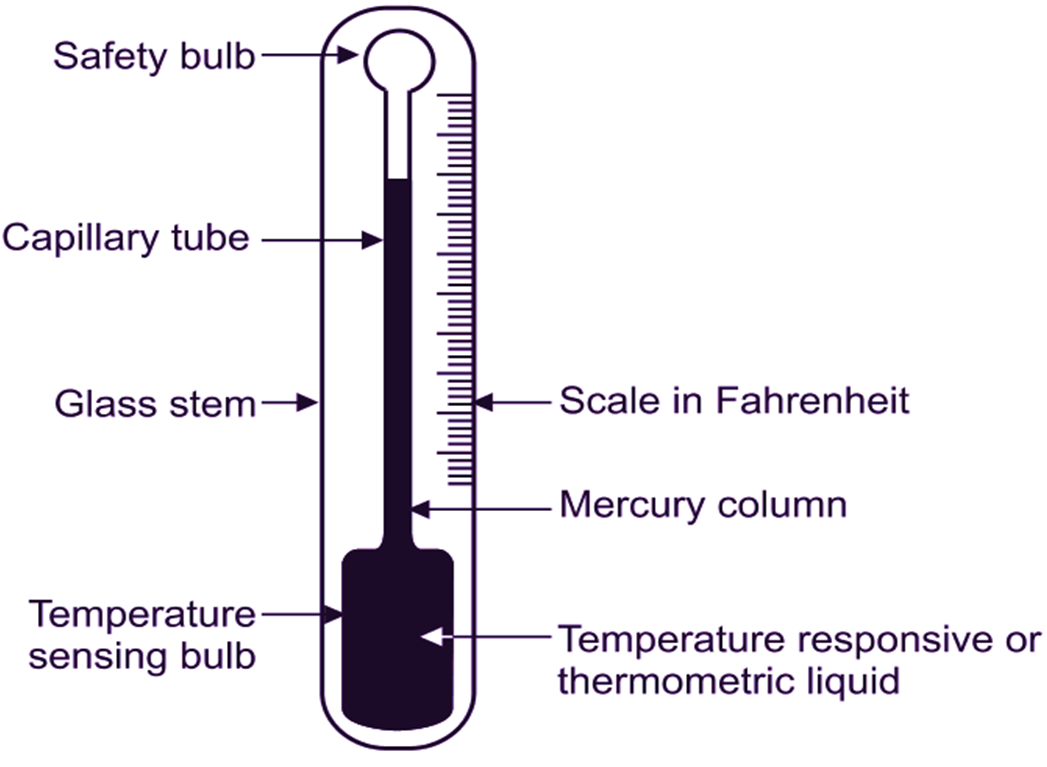

Liquid in glass type thermometer is a thick-walled glass tube casing. Another tube of very small diameter is enclosed inside this glass tube casing. This tube is alled as capillary tube. ower end of capillary tube is shaped in the form of spherical or cylindrical bulb, which is filled with responsive liquid. Generally, Mercury is used as responsive or thermometric liquid. Capillary tube is sealed at top. Accidently, if thermometer comes in contact of extreme high temperature, which is more than its maximum temperature range, then the liquid inside the capillary tube will expand in volume to a much greater extent. It can lead to breakage or damage of capillary tube and thermometer will no longer be able to measure temperature. To avoid such circumstances, a safety bulb is provided at the top of sealed capillary tube in order to protect thermometer. A calibrated scale is engraved on the surface of glass tube for indicating measured value of temperature.

Fig. 2.15: Liquid in Glass Thermometer

Size of capillary tube depends upon the size of sensing bulb, responsive liquid and desired temperature range of thermometer.

Working of Liquid in glass thermometer

When thermometer is placed near the hot body, whose temperature is to be measured, then responsive liquid contained in capillary tube will expand in volume. It causes the liquid to rise in capillary tube. As area of capillary tube is very small, increase in liquid volume will result in significant rise in liquid level. Length of movement of free surface of liquid column (Mercury column) will indicate the temperature, for which, calibrated scale is engraved on the surface of glass tube.

Precautions Taken for Accurate Readings with Minimum Dynamic Error

Precautions to be taken for obtaining accurate readings with minimum dynamic error are,

- Proper contact between sensing element and system, whose temperature is to be measured.

- No heat gain or heat loss from the sensing element to the surrounding.

- Sensing bulb should have good exposure to radiant energy emitted by gas or liquid, whose temperature is to be measured.

- Minimum thermal resistance at sensing bulb.

- Sensing bulb should be cleaned, before use.

- Accumulation (deposition) of any insulating film over the surface of sensing bulb should be avoided.

- It should be ensured that, there is no flow of air or gas around the sensing bulb.

Desirable Characteristics or Properties of “Liquid in Glass Thermometer”

High thermal conductivity of sensing element:

If thermal conductivity of sensing element is low, then it will give slow response to temperature change. Therefore, thermal conductivity of sensing element should be high for fast response to temperature change.

High heat transfer coefficient:

Heat flow rate increases, if heat transfer coefficient of sensing element is high. It makes thermometer to give quick response.

More surface area:

Heat flow rate increases with increase in surface area per unit mass of sensing element. Like heat transfer coefficient, larger surface area also makes thermometer to give quick response.

High velocity of atmospheric air surrounding the sensing element:

Velocity of atmospheric air surrounding the sensing element should be high to get accurate reading of temperature under measurement. If velocity of air passing over the sensing element is low, then there are chances of formation of a film around the sensing element. Due to this film, heat flow rate decreases leading to slow rate of response. As air is passing slowly over the bulb, process of film formation will get enough time to cover sensing bulb and hence, thermometer will not show true value of temperature under measurement.

Temperature Range of Thermometric/Responsive Liquids in a Glass Thermometer

Mercury: – 35°C to 510°C

Alcohol: – 80°C to 70°C

Toluene: – 80°Cto 100°C

Advantages of using Mercury as Thermometric/Responsive Liquid in a Glass Thermometer

- Large span between freezing temperature (- 38.53°C) and boiling temperature (356.73°C).

- Linear coeffcient of thermal expansion.

- Easily available in a very pure state.

- It does not stick to glass surface.

- It is clearly visible through transparent glass.

Advantages of “Liquid in Glass Thermometer”

- Simple and easy to use.

- Low cost.

- Portability.

- Good accuracy.

- Physical damage (If any) of thermometer can be easily checked.

- It is a self-operated system, because no auxiliary power is required for its operation.

- No need of additional indicating instrument.

Disadvantages of “Liquid in Glass Thermometer”

- Cannot be adopted for automatic recording.

- Slow response with respect to change in temperature.

- Time lag in measurement, i.e. time de ay in sensing and indicating the temperature measured.

- Range is limited to 300°C.

- Not suitable for temperature measurement of any distant applicat•on. In other words, it cannot be adopted for remote reading.

Applications of “Liquid in Glass Thermometer”

- Temperature measurement of liquids contained in open tanks, container etc.

- Temperature measurement of cooking kettles, molten metal baths, pipe lines used for fluid flow, air ducts (pipes) etc.

- To record temperature of standard room, calibration room etc.

- Measurement of atmospheric temperature in industries, where, it is necessary to maintain a specific temperature during the occurrænce of some processes.

- Temperature measurement of human body.

- If liquid ins-de sensing bu b is mercury, then “Liquid in glass thermometer” can measure temperature of any fluid having temperature up to 340°C. Mercury has boiling point temperature of 356.73°C. Hence, there is no possibility of evaporation of liquid mercury.

LIQUID IN METAL THERMOMETER (PRESSURE GAUGE THERMOMETER)

Method used: Expansion of liquid due to increase in temperature.

Working principle of Pressure Gauge Thermometer

If temperature increases, liquid expands in volume. This increase in volume of liquid is directly proportional to increase in temperature. Therefore, by measuring increase in volume of liquid, we can carry out temperature measurements.

Construction of Pressure Gauge Thermometer

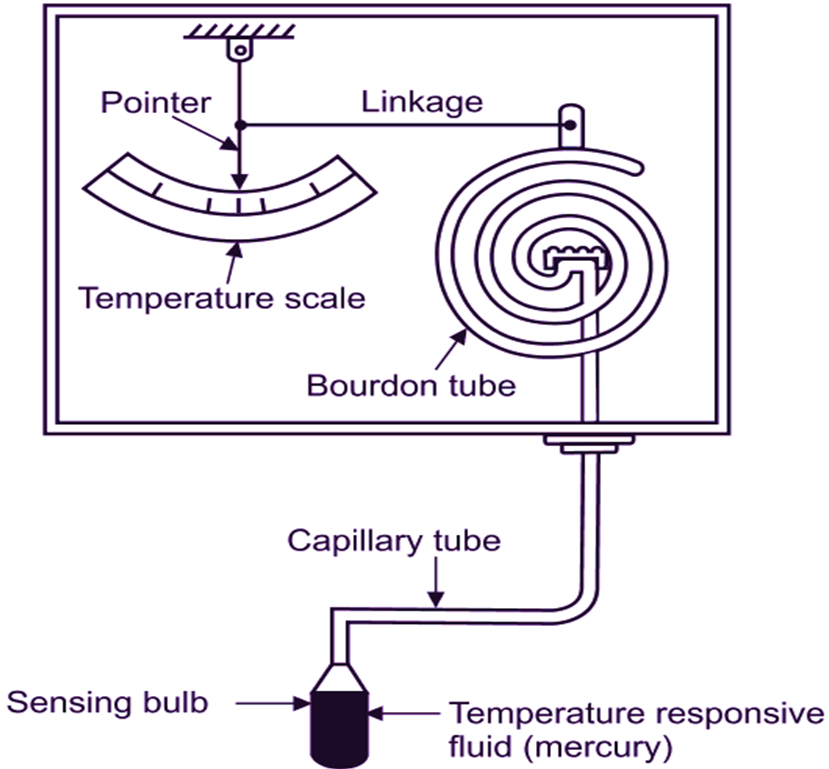

“Liquid in Metal Thermomete# or “Pressure Gauge Thermometer” consists 0f,

Pressure bulb:

Pressure bulb is a sensing element containing thermometer fluid (transmitting fluid or responsive fluid or thermometric fluid). Pressure bulb is a metal tube having cylindrical shape. One end of pressure bulb is closed and other end is connected to capillary tube. It is placed, where temperature is to be measured.

Capillary tube:

It is a tube of very small diameter. Capillary tube is made up of copper or steel for systems using fluids other than mercury. When mercury is used as transmitting fluid, capillary tube is made up of stainless steel. Capillary tube connects the pressure bulb to transmitting system and readout device.

Receiving element:

It is a device, which responds to change in pressure or change in volume of thermometer fluid caused due to change in temperature. Bourdon’s pressure gauge or a bellow or a diaphragm can be used as a receiving element. Receiving element is used to convert change in pressure or change in volume of thermometer fluid (transmitting fluid) into displacement. Displacement so obtained may be amplified to operate a pointer over a stationary scale for indication of temperature.

Fig. 2: Liquid in Metal Thermometer

Advantages of Pressure Gauge Thermometer

- Rigid in construction.

- Low cost.

- Accuracy is good ( ±1

- Fairly good response and sensitivity.

- It is a self-operated system, because no auxiliary power is required for its operation.

- If it is combined with a pneumatic or electrical transmission system for the purpose of magnification, then only auxiliary power is needed for its operation.

- Less maintenance.