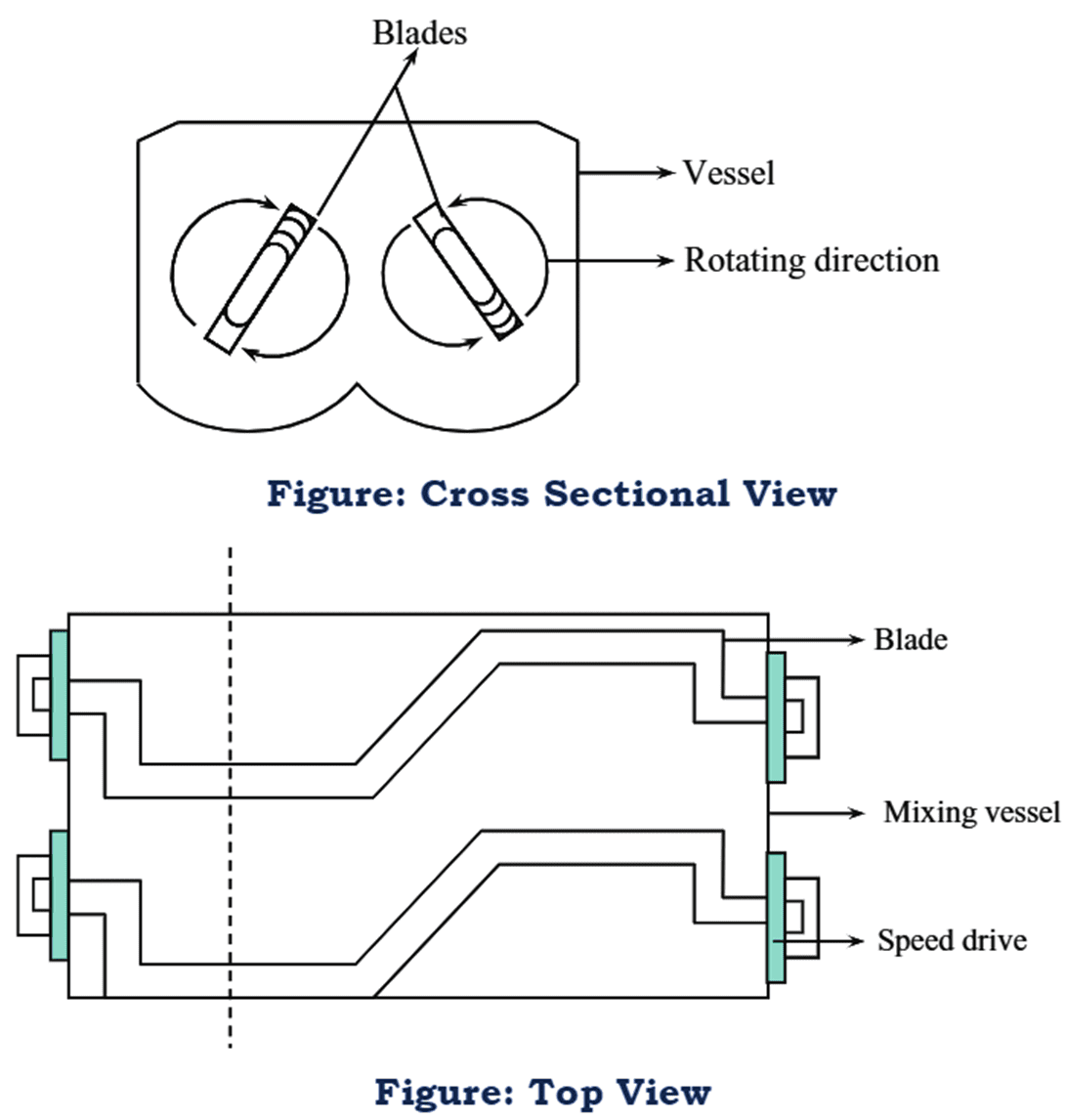

Figure 1: Sigma Blade Mixer.

Working Principle of Sigma Blade Mixer

The working principle involved in Sigma Blade Mixer is shear, which is produced due to inter-meshing and kneading action of sigma shaped blades. It may also involve convective mixing by introducing large amount of materials.

Construction of Sigma Blade Mixer

It is a static mixer which consists of two sigma ($\sum $) shaped blades held horizontally in a double trough-shaped vessel. These blades are connected to a fixed speed drive. The vessel is provided with a rack and pinion drive to facilitate its tilting for product recovery.

Working of Sigma Blade Mixer

Material is introduced into the vessel from the top and blades are rotated with the help of a speed drive. The blades vary in their speeds i.e., first blade rotates at double the speed of second blade producing a pulling action on the material. The blades also move in opposite direction due to which the material is carried to the center from the sides of the vessel.

Distance between the trough and the blades is about 0.03 inches which leads to effective shearing of materials and also prevents the formation of dead spots on the trough walls. Formed lumps and aggregates are broken down by the perforated blades. The process is continued till uniform mixing is achieved. Finally the mixture is collected by tilting the vessel with the help of rack and pinion drive.

Advantages of Sigma Blade Mixer

- It can be closed to prevent the loss of volatile solvents during solid-liquid mixing.

- Formation of dead spots is minimum.

- In addition to solid-liquid mixing, it is also used for solid-solid mixing.

Disadvantages of Sigma Blade Mixer

- Power consumption is mole.

- Blades rotate at a fixed speed.

Applications of Sigma Blade Mixer

1. For mixing dough ingredients (in baking industry).

2. It is used in wet granulation for manufacturing ointments, tablets and pill masses.

3. Used for solid-liquid mixing.