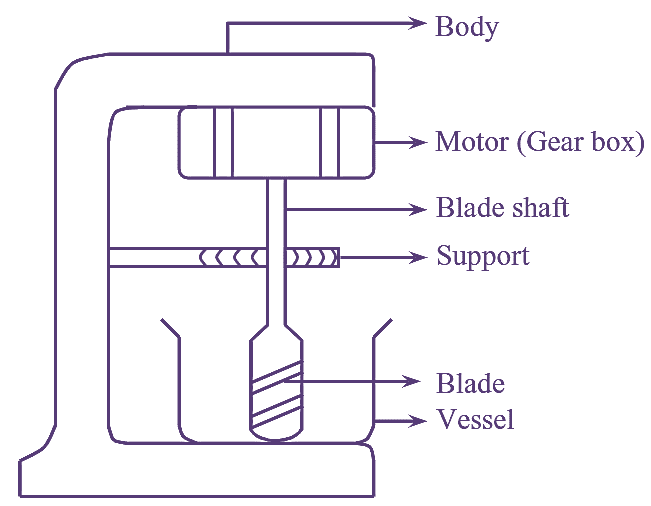

Figure 1: Planetary Mixer.

Working Principle of Planetary Mixer

Planetary Mixer operates on the principle of shear that develops in between the stationary wall and rotating blade. The blade moves around its own axis and also around the central axis which makes it reach every part of the vessel, due to which efficient mixing is achieved. The blade also consists of plates that are slightly sloped in order to enable in the upward movement of the material, thereby inducing tumbling motion.

Construction of Planetary Mixer

It consists of a C-shaped hard metal body provided with a flat bottom and a gear box along with motor at the top. A vessel is placed on the flat bottom, into which a blade is suspended. The blade is connected to the gear box with the help of a shaft. A support is fitted at the centre of the body for holding the blade shaft. The equipment is constructed in such a manner that the vessel and the blade (along with shaft) can be easily removed by slightly raising the blade shaft. The speed of the blade can be altered with the help of variable speed drive.

Working of Planetary Mixer

Its operation is simple. Ingredients to be mixed are added to the vessel and the blade is allowed to rotate. As the motion of blade is planetary, it reaches each and every part of the vessel and mixing is achieved due to the shear developed between the blade and the vessel wall. The curved or slightly sloped blades facilitate size reduction and prevent aggregate formation. Since the blade comes in close contact with the vessel wall, there are no dead spots and hence efficient mixing occurs. The process is continued for long duration, after which the resultant mixture is collected by detaching the vessel.

Advantages of Ribbon Mixer

- Blade speed is adjustable, hence it is more advantageous than sigma and ribbon mixers.

- Apart from solid it can also be used for semisolid mixing.

- Formation of dead spots is avoided.

- Most suitable for wet granulation when compared to other mixers.

Disadvantages of Planetary Mixer

- Power consumption is high.

- Available in relatively small sizes and can be employed only for batch operation.

- Heat may be generated during mixing.

Applications of Planetary Mixer

- Used for mixing thy powders.

- Used to produce kneading action, as required in wet formulation.

- Used in the manufacture of ointments and sustained-release formulation.