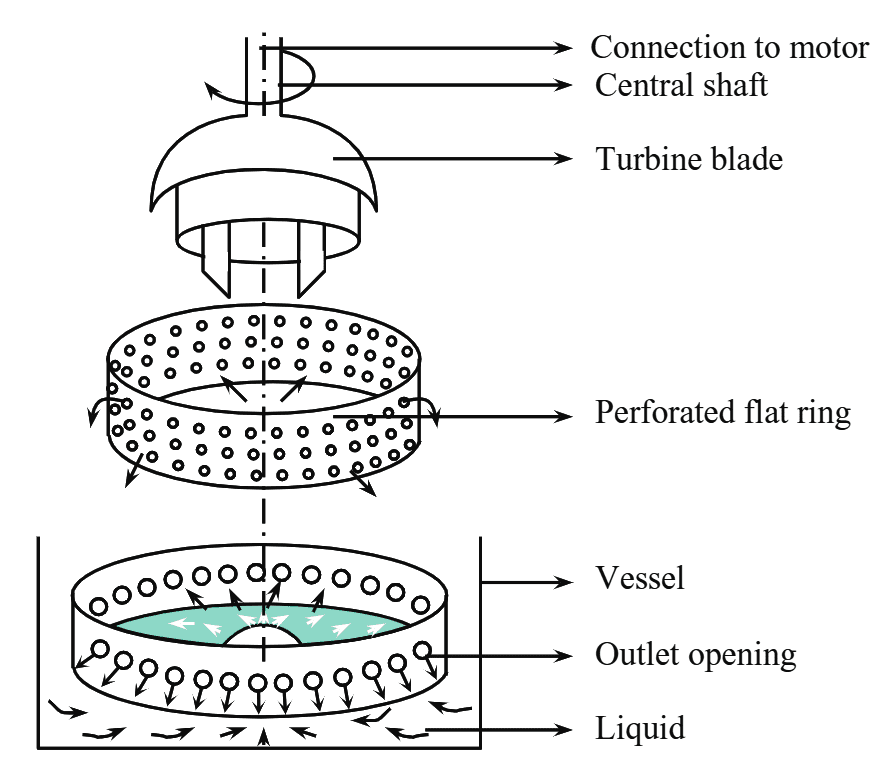

Figure 1: Silverson Emulsifier Mixer.

Working Principle of Silverson Emulsifier Mixer

The high speed rotor produces turbulence and intense shearing forces which facilitates the penetration of the liquid through the perforated metal sheets. Suction is applied to the liquid from the bottom of the head which allows the liquid to remain in continuous motion. As a result, liquid breaks and gets dispersed as smaller globules.

Construction of Silverson Emulsifier Mixer

Silverson Mixer consists of a perforated emulsifier head into which perforated flat ring is placed. There is a central shaft that holds the turbine blade. One end of the shaft is connected to the motor and the other end to the emulsifier end. This entire assembly is placed in a vessel. There are four to five supporting columns that connect the motor shaft and the emulsifier head in series.

Working of Silverson Emulsifier Mixer

The vessel is filled with immiscible liquids and the emulsifier head is placed into it such that it gets completely dipped in the liquid. Turbine blade along with the perforated flat ring is also placed inside the head. The shaft is allowed to rotate with the help of a motor which facilitates circular movement (rotation) of turbine blades along with the emulsifier head. As a result, the liquid is sucked from the vessel into the head, through the hole provided at the centre of the head.

Due to centrifugal force, the liquid inside the head is expelled through minute perforations. This causes the liquid to break into small globules which get dispersed due to continuous rotation. Turbine blade is rotated at relatively high speed for easy suction and forced expulsion of the liquid in order to achieve efficient mixing.

Advantages of Silverson Emulsifier Mixer

- Suitable for both small scale and large scale mixing as it is available in different sizes.

- It can be used for both continuous and batch type operation.

- The process is rapid and yields emulsions of fine particle size.

- Easy to clean and maintain.

Disadvantages of Silverson Emulsifier Mixer

- Perforations may get blocked in some cases.

Applications of Silverson Emulsifier Mixer

- Used in the manufacture of creams and emulsions.