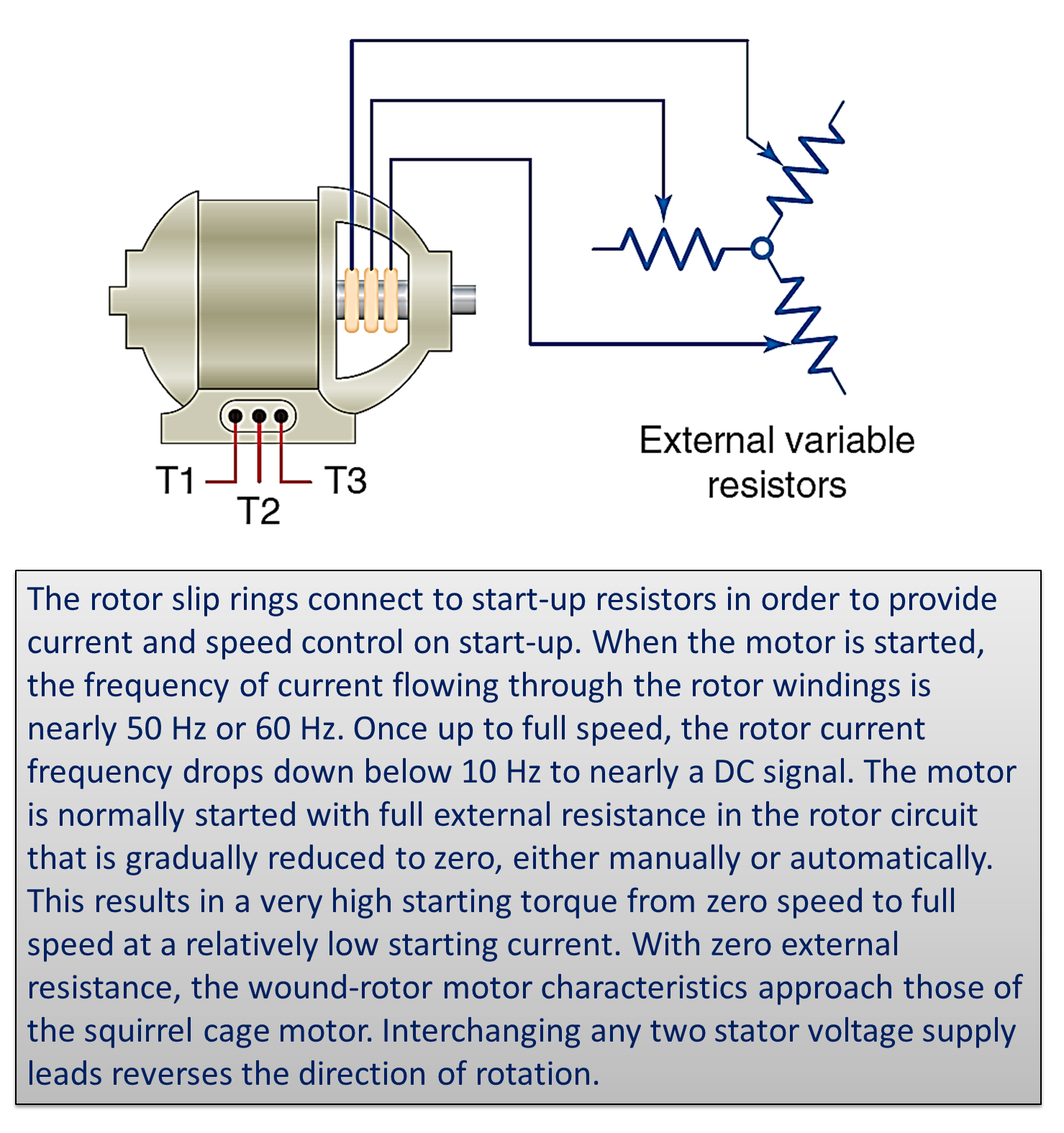

Slip Ring Induction Motor also called Wound Rotor Induction Motor. Induction motors employing slip ring rotor are said to be slip ring induction motors. They consist of three phase winding connected in star internally, the other three ends are brought out and connected to other slip rings. These three ends get short circuited automatically when the motor is running. Therefore because of inclusion of external resistance in rotor circuit, it is possible to control the starting torque. Hence the rotor is wound with same number of poles as that of stator.

Construction of Slip Ring Induction Motor

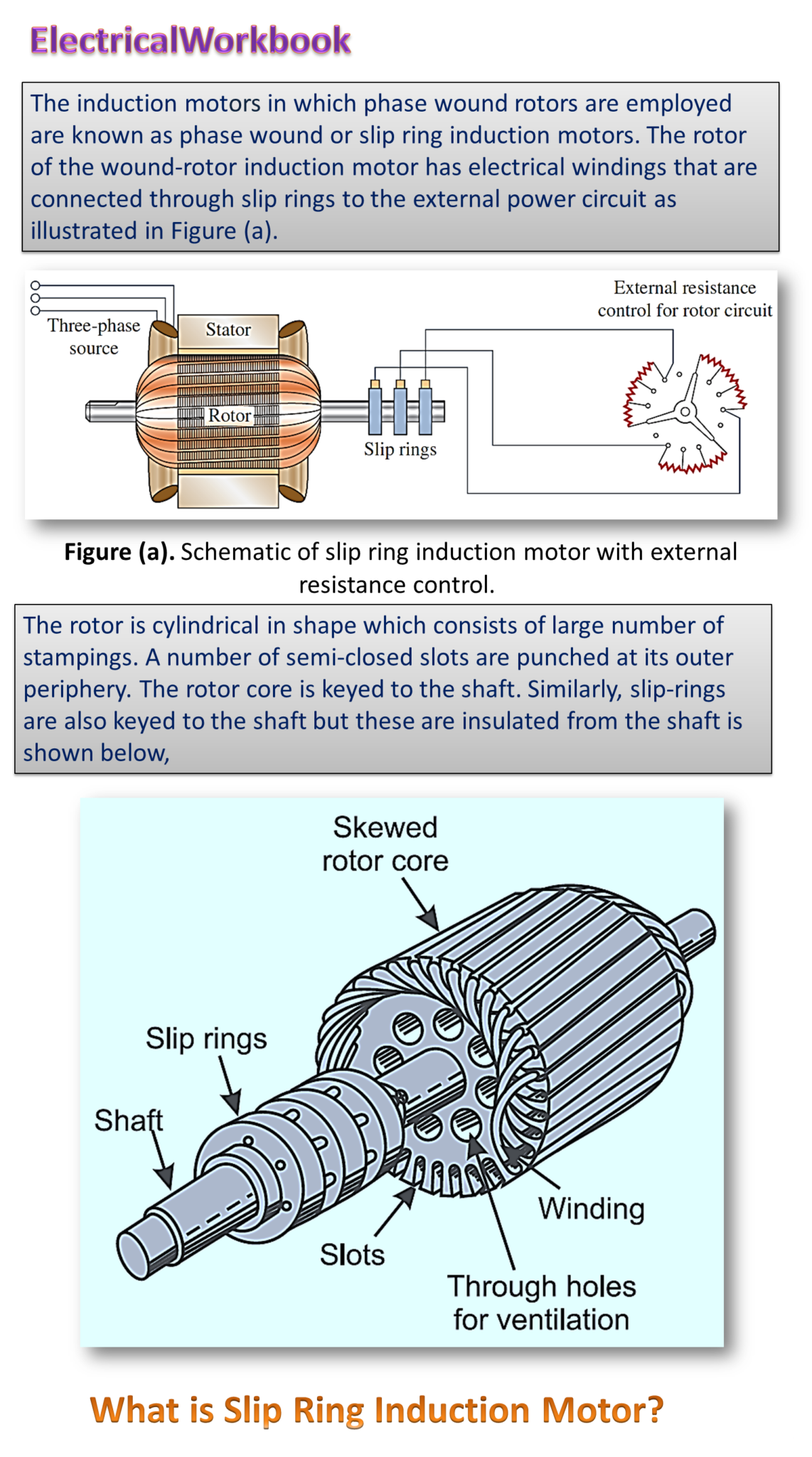

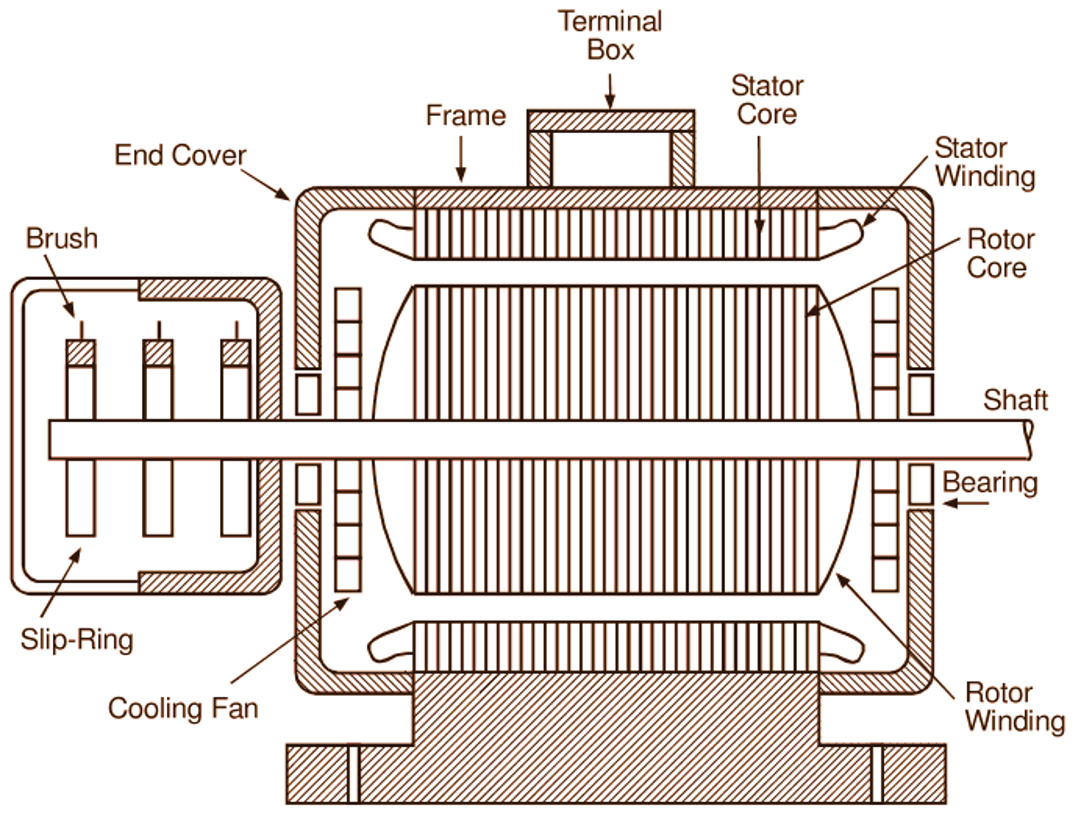

The stator and rotor of this type of motor (Fig. 1) also have laminated construction for their cores.

Fig.1: Wound Rotor Induction Motor

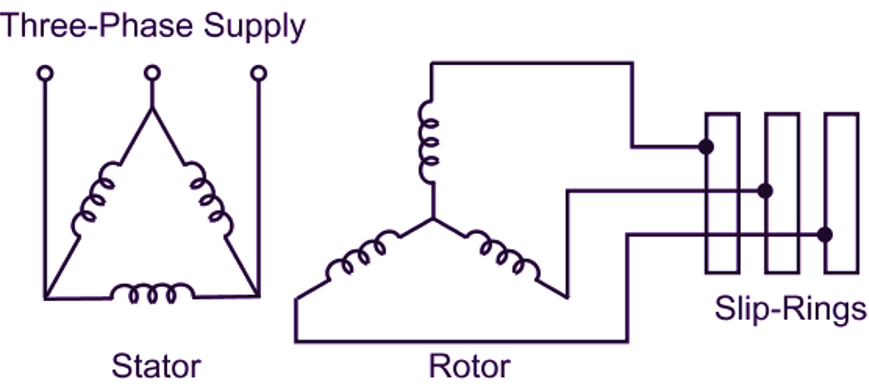

The stator of this motor has three phase star or delta connected winding similar to the stator of the squirrel cage induction motor. The rotor also carries a similar three phase star connected winding. Both stator and rotor are wound for the same number of poles. The open ends of the rotor windings are brought out to three insulated rings called slip rings. These slip rings are mounted on the motor shaft and bear the brushes. This arrangement allows the insertion of external resistance in series with each phase of the rotor for starting or speed control purposes. When running normally, the slip-rings are short circuited. Thus under running condition, even the wound rotor is short circuited on itself just like squirrel cage rotor. Fig. 2 shows the schematic representation of a three phase slip-ring induction motor.

Fig. 2: Schematic representation of a 3-phase slip-ring induction motor.

Working of Slip Ring Induction Motor

Characteristics of Slip Ring Induction Motor

This motor has high starting torque and low starting current. Its speed is maximum at no load and drops with the increasing of load. The speed can be controlled up to 5

Applications of Slip Ring Induction Motor

It is widely used for high starting torque and low starting current as in centrifugal pumps, elevators, etc.

Advantages of Slip Ring Induction Motor

- High starting torque.

- Low starting current.

- Speed control is obtained up to 5

Disadvantages of Slip Ring Induction Motor

- It has more cost.

- More maintenance, because the rotor is to be connected to the external circuit.