Working Principle of Steam Jacketed Kettle (Evaporation Pan)

Steam Jacketed Kettle is filled with aqueous extract and steam is supplied through the space between the jacket and kettle. The heat from steam gets transferred to the aqueous extract by conduction and convection processes. This raises the temperature of the extract, thereby enhancing the vaporization of the volatile solvent. The rate of vaporization can be further enhanced by agitating (stirring) the extract.

Construction of Steam Jacketed Kettle

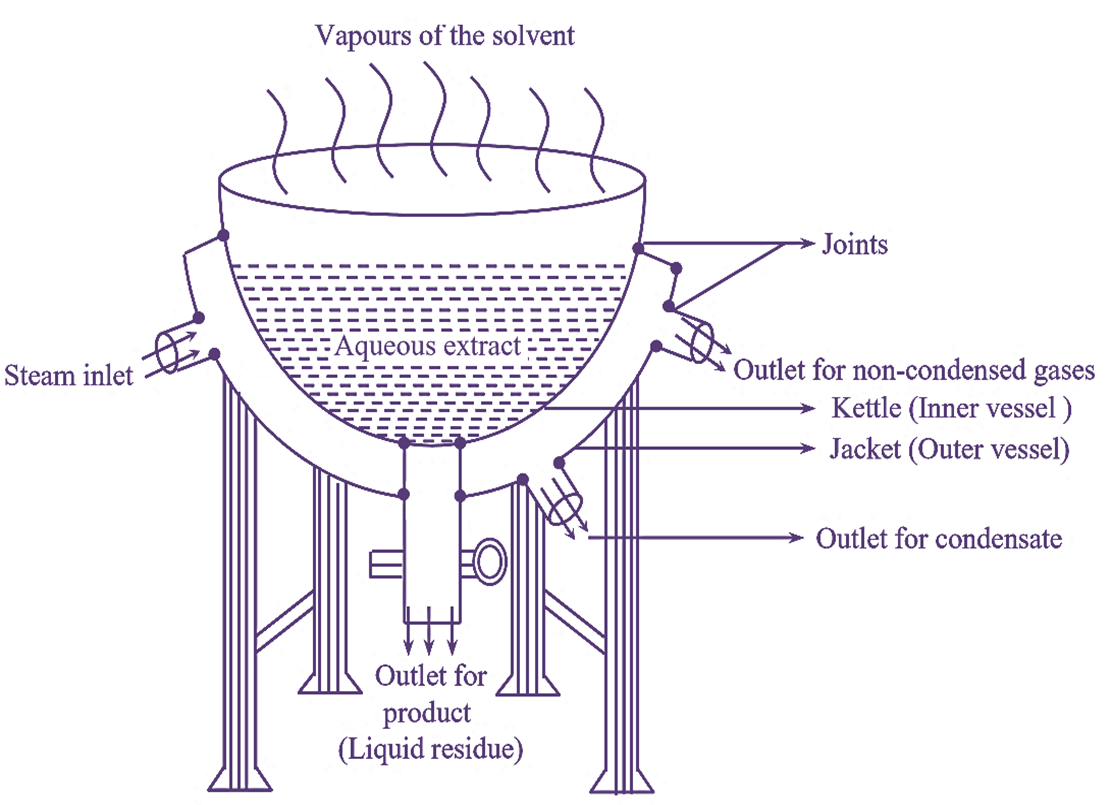

Figure 1: Steam Jacketed Kettle (Evaporation Pan).

The Steam Jacketed Kettle unit is hemispherical in shape. Kettle or inner vessel is made up of copper, as it possesses good conductivity. Copper is replaced by tinned copper if acidic materials are to be handled (see Figure 1). The kettle is enveloped with an outer vessel called jacket which is made up of iron and hence possesses minimum conductivity. Iron may undergo rusting, hence it is tinned or enamelled on its inner side. The jacket is fixed by joints to the kettle. At one side of the jacket, an inlet is provided for steam and on the other side an outlet (vent) for non-condensed gases is present. At the bottom of the jacket, an outlet is provided for the removal of condensate and another outlet for removal of the product.

Working of Steam Jacketed Kettle

Aqueous extract of the drug is taken in an evaporating pan of 90 liters or more capacity. Steam supplied through the inlet pipe, circulates within the cavity of jacket and kettle. Heat is then transferred to the aqueous extract by conduction and convection. The contents of the kettle are stirred occasionally. Initially, evaporation occurs at a faster rate which later decreases when the aqueous extract starts to concentrate.

The steam eventually loses its kinetic energy and undergoes condensation. This condensate is collected from the bottom of the evaporating pan. The product (liquid residue) is collected from the bottom of the kettle having a capacity of more than 90 liters. If the capacity of the kettle is ≤ 90 liters, then the product is obtained by tilting the container.

Adequate ventilation should be provided, which can be achieved by operating fans in the room as this helps to remove the vapours thereby enhancing the rate of evaporation as saturated air over the liquid is quickly removed.

Advantages of Steam Jacketed Kettle

- Evaporating pan can be operated on small scale as well as on large scale.

- Design of this equipment is very easy.

- It can be constructed using several materials like aluminium, stainless steel, copper etc.

- It is easy to stir the contents in an evaporating pan.

- Thermostable materials can be concentrated.

- Maintenance of the equipment is easier.

Disadvantages of Steam Jacketed Kettle

- Temperature cannot be regulated in the evaporating pan.

- As the equipment is of open type, neither pressure of the solvent nor the boiling point of water is reduced.

- Saturation of the air above the evaporating pan decreases the rate of evaporation.

- Heating area decreases as the product gets concentrated.

- Thermolabile materials cannot be evaporated due to longer periods of exposure.

- It is expensive as heat economy is poor.

- Poor heat transfer coefficient leads to the formation of scums (films) at the bottom of the evaporator.

Applications of Steam Jacketed Kettle

- It is used to concentrate only aqueous form of extract.

- It is also used to concentrate the extracts which are stable to temperature (thermostable extracts). E.g: Liquorice extract.