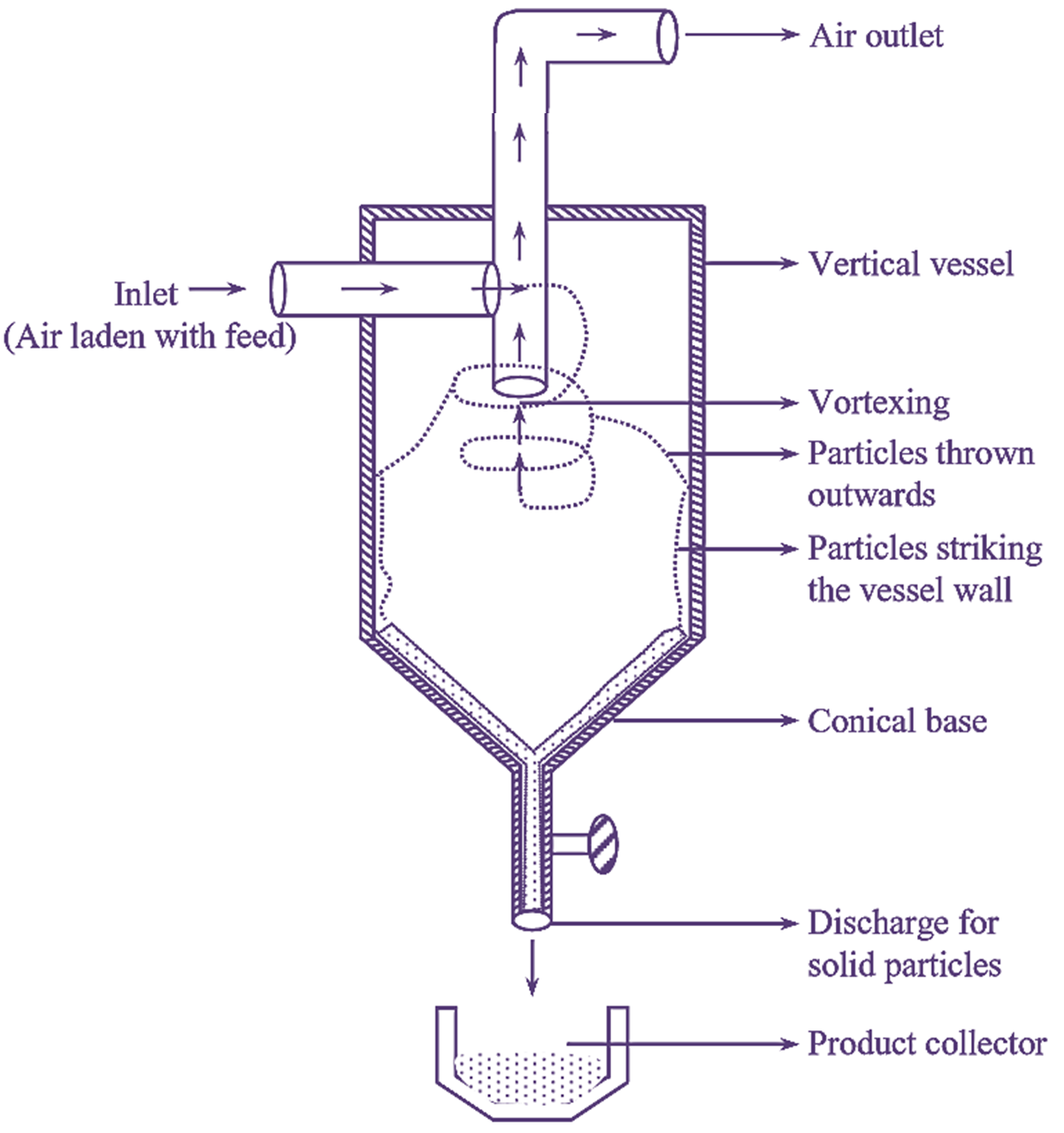

Figure 1: Cyclone Separator.

Working Principle of Cyclone Separator

Centrifugation is the main principle involved in the separation of solids from fluids through cyclone separator. Such separation is done on the basis of particle size as well as particle density. Larger particles with greater density under the influence of centrifugal force are thrown outwards and are collected first then successive particles with relatively less size and density are collected.

Construction of Cyclone Separator

The cyclone separator consists of a vertical cylinder which is conical at the bottom (see Figure 1). The top portion of the cylinder consists of a flat plate. The equipment possesses an inlet for feed (solid and air mixture) towards the lateral side and an air outlet on the top portion. The air (fluid) outlet extends into the separator for certain distance much below the feed inlet.

This arrangement prevents the air from short-circuiting directly from the feed inlet to the air outlet. The base is provided with an outlet for recovery of the solids.

Working of Cyclone Separator

Feed (air laden with solid material to be size separated) is introduced into the vertical cylinder through the feed inlet at a very high velocity. As a result, rotary movement takes place inside the vessel. Solid particles are under the influence of centrifugal force and vortexing force (air spins around very fast and pulls the solid particles into its empty centre). Larger particles with greater density are thrown outwards, they strike the vessel wall and as the velocity is reduced they fall to the base of the vessel. They are then collected from the bottom of the vessel through the solid outlet into a hopper or chute.

Later particles with relatively smaller size and low density are collected successively. Air leaves the vessel through the air outlet at the top.

Advantages of Cyclone Separator

- The process takes place at a faster rate.

- Efficiency is high.

- Very fine particles can also be separated.

Disadvantages of Cyclone Separator

- Energy input is more.

- Large amount of air has to be introduced.

- Requires special equipment.

Applications of Cyclone Separator

- Cyclone separator is used for the separation of solids from liquids (liquid cyclone).

- It can also be used for the separation of fines and dust particles from coarse particles.

- Used for the separation of crystal magma such as lactose and sodium bisulfate.

Modification of Cyclone Separator

Cyclone separator can also be used for the separation of solid particles suspended in liquid. In such case, the equipment is referred as wet or liquid cyclone. This is also based on the difference in the density of solid and liquid particles. Water is more viscous when compared to air, hence for the separation of solid particles suspended in liquid, more centrifugal force has to be applied. Centrifugal force can be enhanced by reducing the diameter of the vessel. When cyclone separator is under operation, coarse particles under the influence of centrifugal force are thrown outwards. i.e., towards the walls of the vessel and are collected from the base. The lighter particles along with liquid escape from the outlet on top of the vessel.