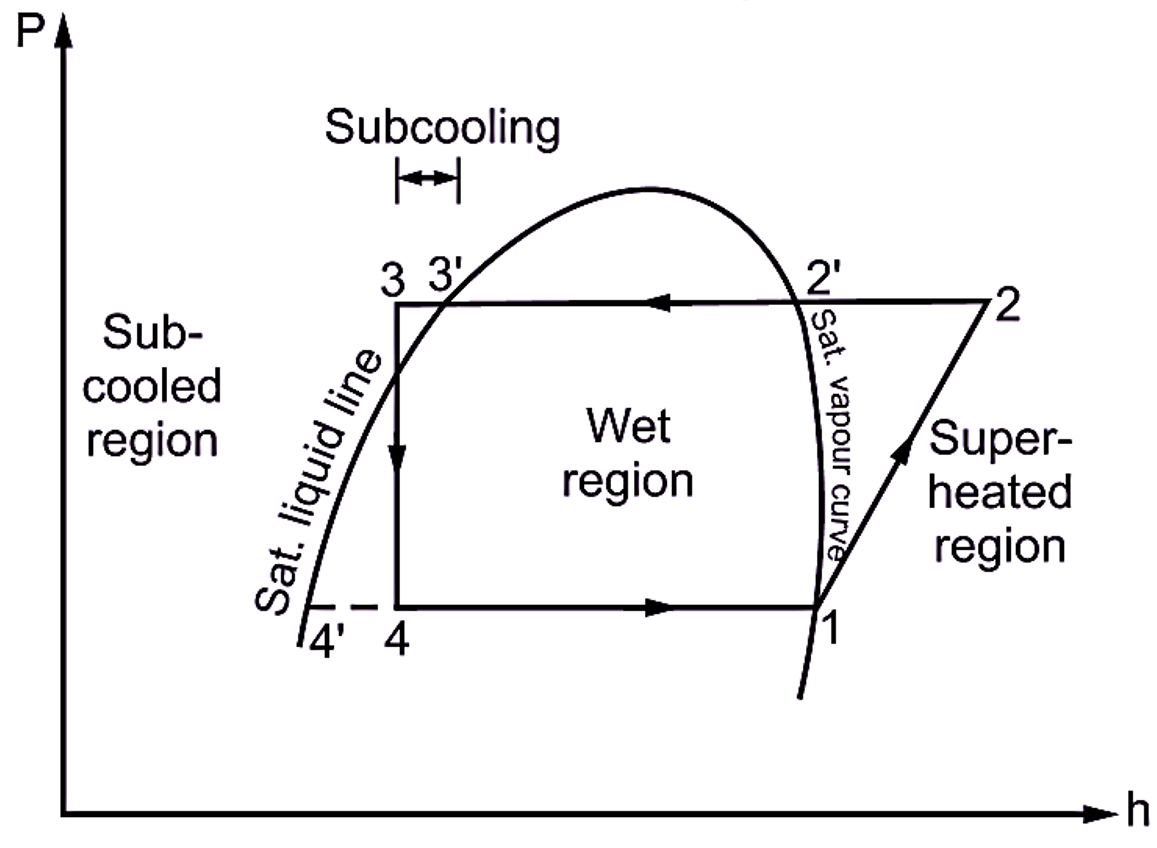

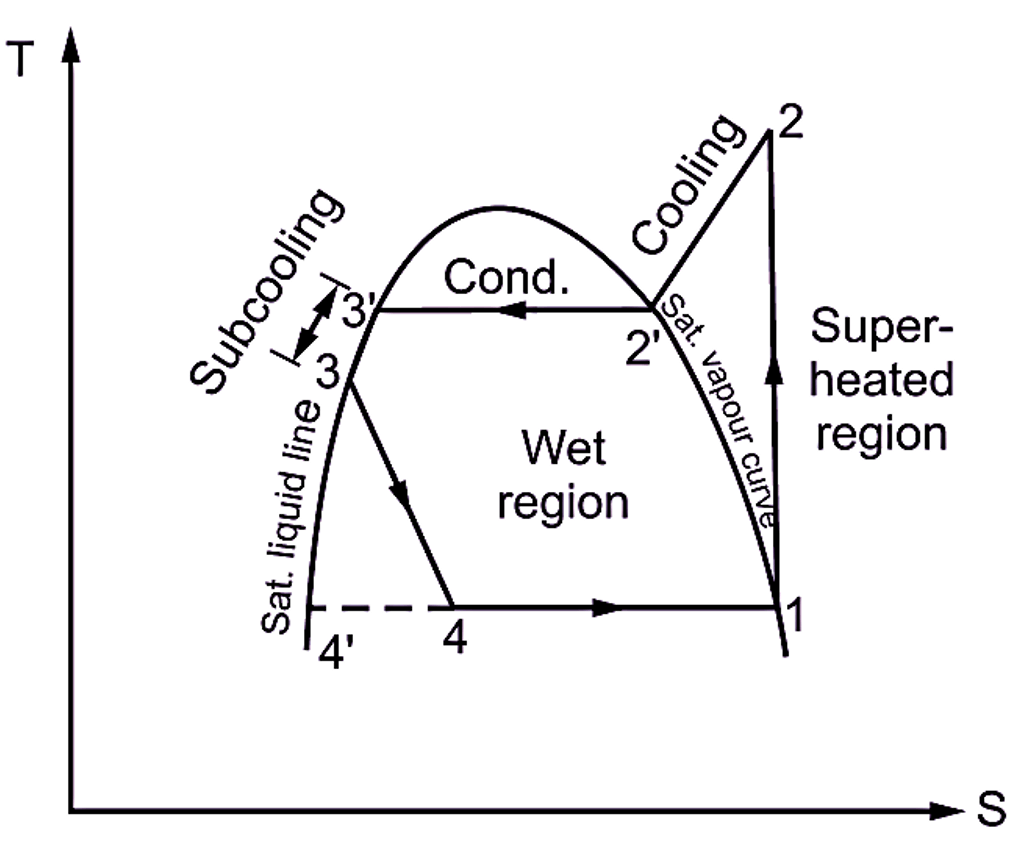

Subcooling or undercooling is defined as, “the process of cooling the refrigerant below condenser temperature for given pressure”. After undergoing the cooling and condensation process (2-3′), the liquid refrigerant is further cooled below the condenser temperature (i.e. saturation temperature, T’3 ) up to temperature T3 along liquid line (curve) before the start of compression process. Such a process is also called as ‘undercooling’ of refrigerant and is generally done along the liquid line. Refer T-S diagram shown in Fig. 1, where subcooling or undercooling is represented by curve 3′-3 along saturated liquid line or curve,

Fig. 1: Representation Of ‘Subcooling’ on P — h and T – S charts

Effects of Subcooling on coefficient of performance (COP)

Due to subcooling, the refrigerating effect increases. Therefore, COP of system increases. Also, the required mass flow rate of refrigerant (m) per tonne of refrigeration reduces and it is less as compared to simple saturated cycle. Therefore, less amount of refrigerant is required for the refrigeration system of same capacity. This saves cost of refrigerant. Since required quantity of refrigerant is reduced, therefore, the volume of vapour refrigerant to be handled by compressor reduces. Therefore, comparatively less power is required to run the refrigeration system for obtaining the desired refrigerating effect. Subcooling is desirable, because it increases refrigerating effect and reduces the required compressor power. Since COP is ratio of refrigerating effect to work done, therefore, COP of system increases. Thus, the ultimate effect of the undercooling or subcooling is to ‘increase the value of coefficient of performance’ under the same set of conditions.