Vapour absorption refrigeration system is quite similar to the vapour compression refrigeration system from design and construction point of view. Like vapour compression refrigeration system, it has condenser, expansion device and evaporator. Only the compressor used in vapour compression refrigeration system is replaced by an assembly of components such as an absorber, pump, pressure reducing valve and a generator. Vapour absorption refrigeration system uses heat energy instead of mechanical energy to change the condition of refrigerant, which is essential requirement for the operation of any refrigeration system to produce refrigeration, Therefore, vapour absorption refrigeration system is called as a heat operated system or thermal energy driven system. Here, compressors are not used. It is quite similar to the vapour compression refrigeration system, which uses mechanical energy to change the condition of refrigerant. For this purpose, compressors (either reciprocating type or rotary type or centrifugal type) are employed in vapour compression refrigeration system. In both the refrigeration systems (i.e. vapour compression and vapour absorption), evaporator and condenser are present. The process of evaporation and condensation of the refrigerant takes place at two different pressure levels to achieve refrigeration in both the refrigeration systems. However, method used to create two different pressure levels for evaporation and condensation of the refrigerant is different in these two systems. In addition to method used for creating different pressure levels, the method used to circulate the refrigerant in the refrigeration system is also different in these two systems.

Necessity of Vapour Absorption Refrigeration System

Vapour compression system is comparatively more efficient than vapour absorption system. However, the mechanical energy required to run the compressor of vapour compression system is obtained from electricity. Since electricity is a high grade energy, it is very expensive. Therefore, operating cost of vapour compression refrigeration system is more. Also, in vapour compression system, the refrigerant is compressed so as to increase its pressure and power or work required is relatively large for compression of vapour refrigerant, which undergoes large change in specific volume. Thus, if any other method is available for increasing the pressure of refrigerant from evaporator pressure to condenser pressure without considerable change in specific volume, then it is possible to reduce the required amount of input energy to greater extent. In order to achieve this, vapour absorption refrigeration system is used.

Advantages of Vapour Absorption Refrigeration System

- Less wear and tear due to less number of moving parts.

- No compressor or any reciprocating component is required.

- Use of low grade energy (heat energy) to change the condition of refrigerant leaving the evaporator.

- No refrigerant leakage problem.

- Less noisy, because the system has only one moving part (i.e. pump).

- Exhaust steam may be used as a source of heat energy in the generator.

- System can be used in remote places, where availability of electricity is a problem.

- Easy to control.

- Partial load performance (i.e. performance at part load) is better.

- Load variations do not affect the performance of system.

- Less overall cost.

- Environment friendly.

- More life.

Disadvantages of Vapour Absorption Refrigeration System

- Lower COP.

- It takes more time to produce the same refrigerating effect, as compared to VCC.

- Bulky in size.

- Costly pump is required.

- If kerosene is used for supplying heat energy to the generator, it gives out bad smell.

Applications of Vapour Absorption Refrigeration Sytem

- Vapour absorption refrigeration system is used in the applications, where availability of electricity is a problem.

- Vapour absorption refrigeration system is used in the applications, where solar energy is available.

- Lithium bromide absorption refrigeration systems are extensively used in large capacity air conditioning systems.

- Chilling of drinking water.

- Chilling of beverages and fruit juices.

Lithium Bromide Absorption Refrigeration System or Li – Br Absorption Refrigeration System

Refrigerant used: Water.

Absorbent used: Lithium bromide solution.

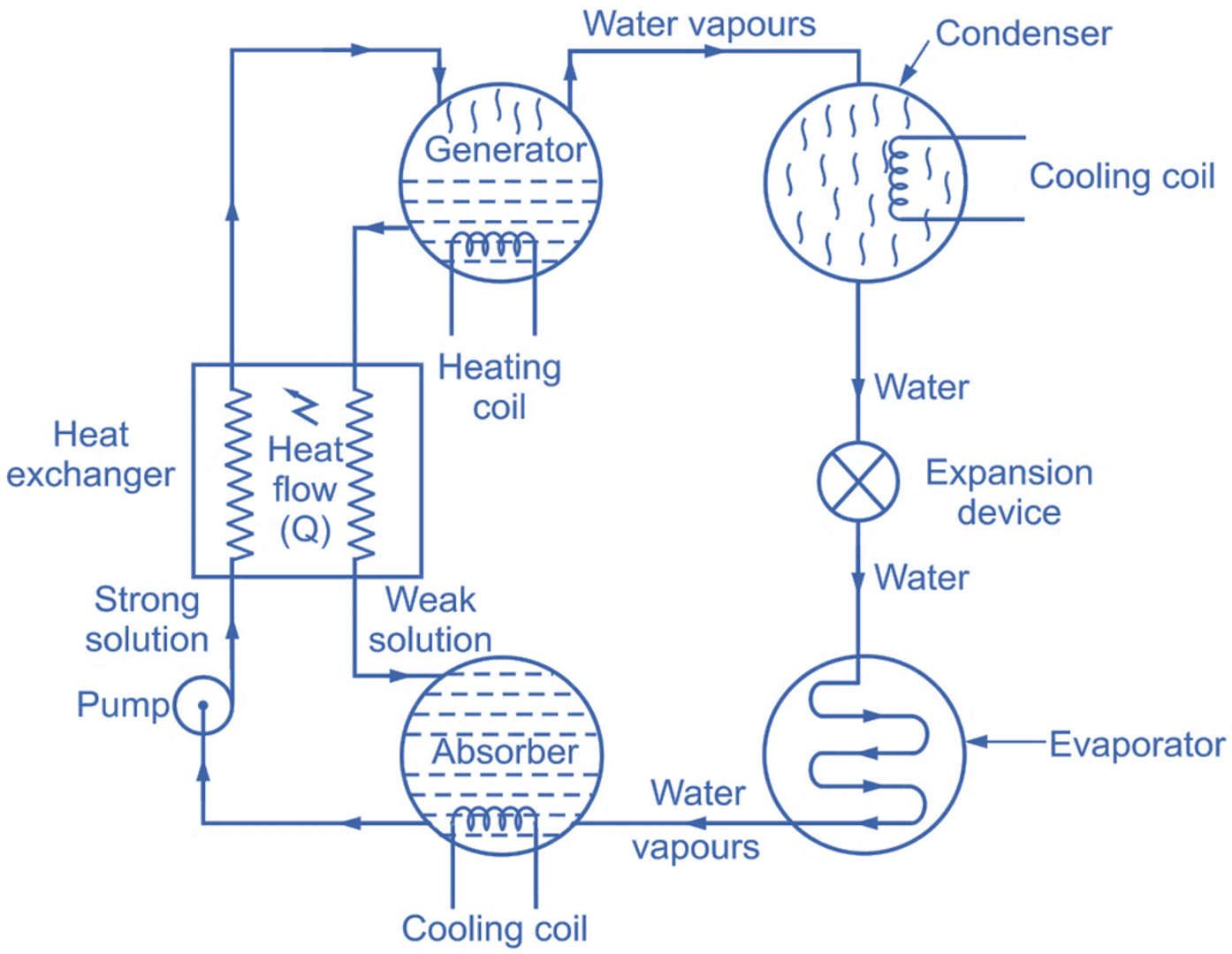

Fig. 1: Lithium bromide absorption refrigeration

Working principle of Lithium Bromide Absorption Refrigeration System

Lithium Bromide Absorption Refrigeration system works on the principle that, ‘When water and lithium bromide solution are placed in a closed evacuated system, the water gets evaporated.’

Construction of Lithium Bromide Absorption Refrigeration System

The essential components of simple Lithium bromide absorption system are,

- Evaporator.

- Absorber.

- Pump.

- Heat exchanger.

- Generator.

- Condenser.

Working of Lithium Bromide Absorption Refrigeration System

After leaving the evaporator, water vapours enter the absorber, where they are absorbed by the lithium bromide solution present in the absorber (Figure 1). The lithium bromide solution has ability to absorb large quantity of water vapours. Some form of cooling arrangement is employed to remove the heat of absorption evolved in the absorber. For example: Cooling coil using chilled water. This is done in order to increase absorption capacity of ithium bromide solution, because at higher temperature; lithium bromide solution absorbs less water vapours. After the absorption of water vapours by lithium bromide, the strong solution so formed is then pumped into the generator. The strong solution of lithium bromide in generator is heated by some external heat source such as heating coil using hot gas or steam. During the heating process, the water present in the strong solution gets evaporated. So formed water vapours are driven to the condenser at high pressure leaving behind the hot weak lithium bromide solution in the generator. This hot weak lithium bromide solution flows back to absorber. The water vapours are condensed in the condenser to give water as condensate (i.e. output of condenser). This water is sent to expansion valve and then to evaporator. Water absorbs its latent heat of vapourization in the evaporator and gets vapourized to give water vapours. Due to heat absorbed by water from the space to be cooled, refrigeration is achieved. These water vapours so formed are supplied to absorber. This completes the cycle of vapour absorption system. The strong solution entering the generator must be heated to vapourize and separate the water vapours, whereas, the weak solution contained in the absorber must be cooled, to draw maximum amount of water vapours from the evaporator. For this purpose, a heat exchanger is employed between the absorber and generator. In heat exchanger, heat from hot weak solution is transferred to the strong solution, which is comparatively cold. Therefore, arrangement of heat exchanger reduces cost of heating in generator and cost of cool ng in absorber.

Advantages of of Lithium Bromide Absorption Refrigeration System

- Pressure inside the system is below atmosphere. Therefore, Electrolux refrigerator is light in weight and there is no danger of bursting, leakage etc.

- Since the refrigerant used (water) is non-toxic, Electrolux refrigerator can be directly used for chi led coil in case of the air conditioning applications.

- Low operating cost.

- Low maintenance cost.

Disadvantages of of Lithium Bromide Absorption Refrigeration System

- Lithium bromide solution is corrosive. Therefore, inhibitors should be added to protect metal parts against corrosion.

- All joints and connections should be made leakproof to prevent leakages in to the system, since the system works under vacuum.

Practical Applications of Lithium Bromide VAS

- Air conditioning.

- Chilling of drinking water.

- Chilling of beverages.

- Chilling of fruit juices.